CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Authorized Field Service Facility

for technical troubleshooting assistance before you proceed.

TORCH PART CONFIGURATIONS

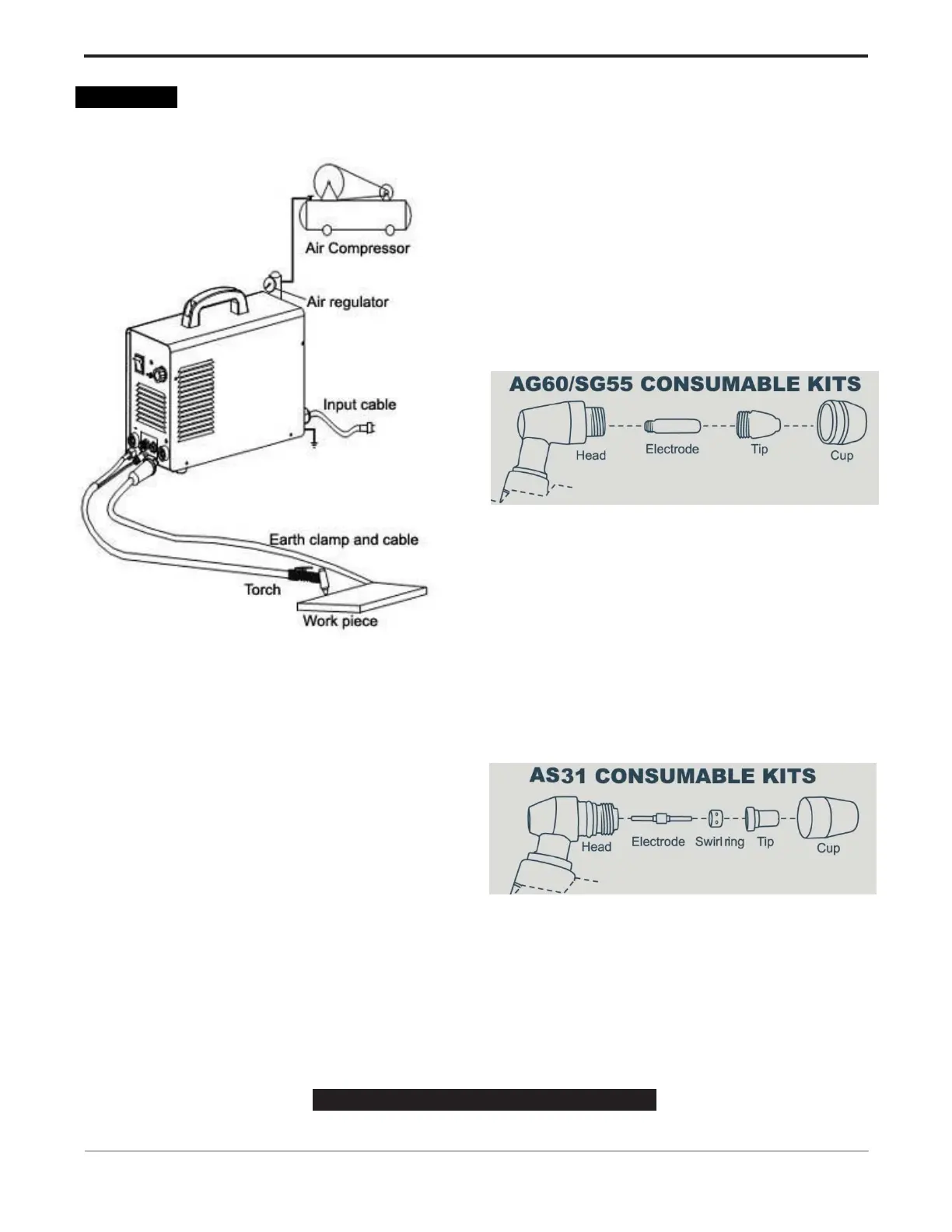

Connection

The RBC5000DL uses a standard cutting setup as

described below.

Standard Cutting Setup:

In the Standard Cutting configuration the nozzle is

designed not to touch the work piece. The advantage

of this cutting method is good visibility of the arc.

However it requires a steady hand to avoid touching

the nozzle to the work piece which will cause

premature nozzle wear and a jagged cut. An optional

drag spacer can be attached to the retaining cap to

maintain a consistent arc height.

The CUT40/RBC5000/RBC5000D uses a standard

cutting setup as described below.

Standard Cutting Setup:

In the Standard Cutting configuration the nozzle is

designed to touch the work piece. The advantage of

this cutting method is good visibility of the arc.

However it will cause premature nozzle wear and a

jagged cut.

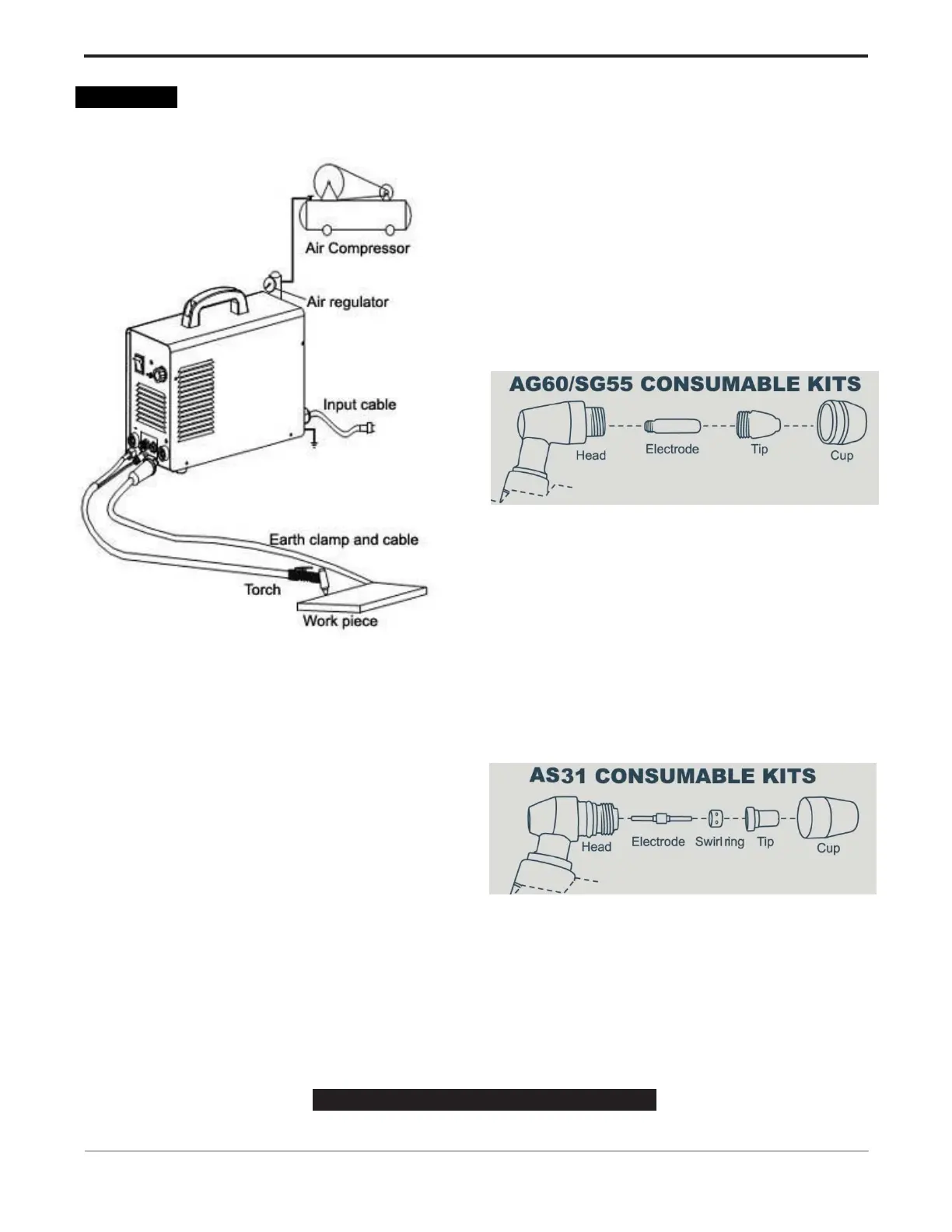

ALWAYS USE GENUINE “REBOOT” ELECTIC

ELECTRODES, NOZZLES, AND EXPENDABLE

PARTS FOR THE BEST CUTTING PERFOR-

MANCE.

Loading...

Loading...