11

Installation

Submersible DEF Pump Assembly

If no column pipe assembly or fixed pressure relief valve was purchased it is mandatory the

contractor follow the ISO 22241 guidelines. Pressure relief must be used with all systems to

limit discharge pressure to 50 psi (344.7 kPa). Any fixed length plumbing needs to allow for

proper clearance to bottom of tank per Figure 3. Ensure all sealants are DEF compatible and

use only stainless steel plumbing and hardware to avoid any product contamination. It is

required that if a fixed pressure relief system is not selected, the optional adjustable

pressure relief must be installed in the manway.

Plastic pipe is not recommended for support of pumps in any applications.

Manway Fittings And Connections

Take caution of fitting and plumbing routing, size and materials to assure adequate performance and material

compatibility per ISO 22241.

Installing the Pump

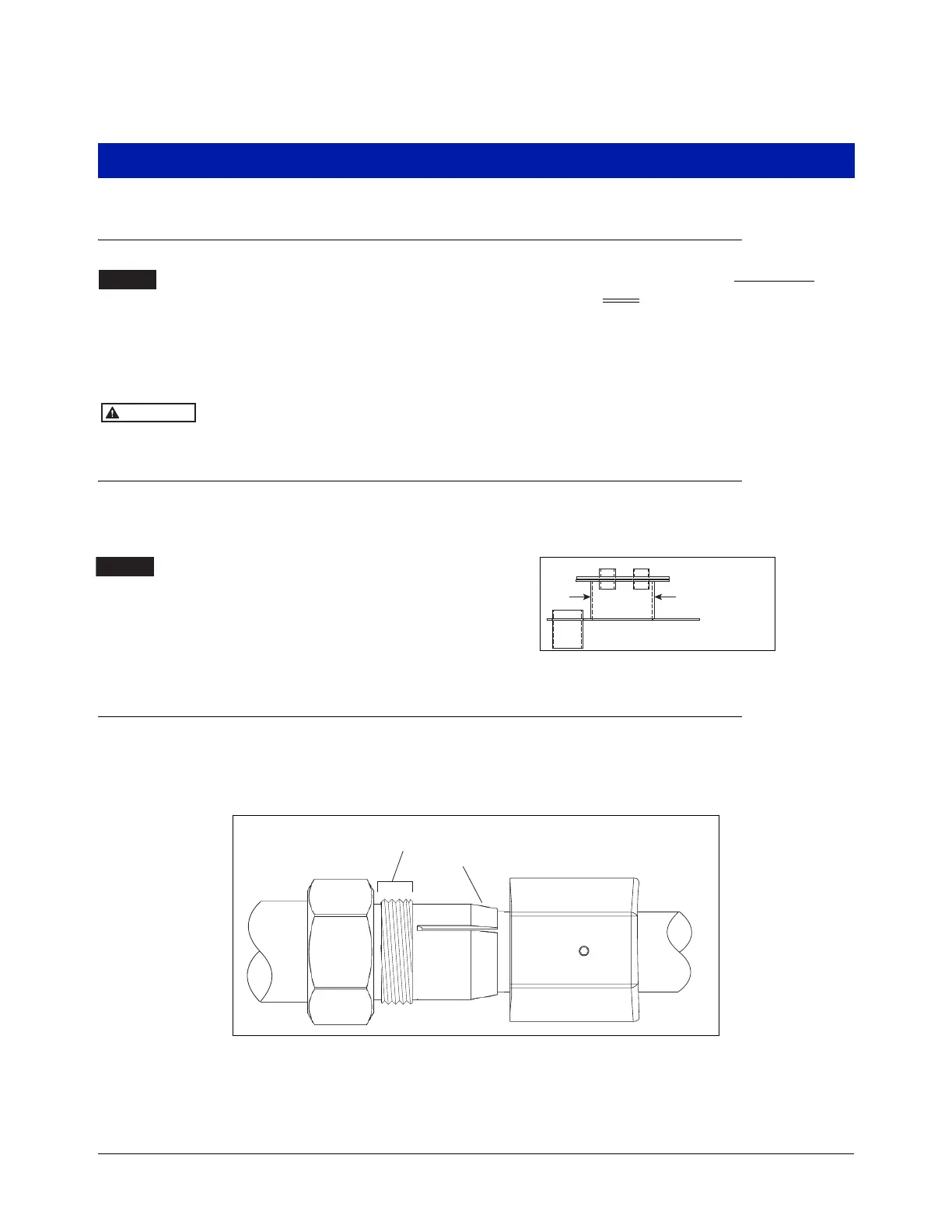

1. Before installing pipe threads apply an adequate amount of fresh, UL classified for DEF, non-setting thread

sealant. Loctite 567 sealant is recommended with Loctite 7090 primer for all field serviceable pipe threads.

Loctite 8009 is to be used as the DEF compatible antiseize on the clinch nut threads (see Figure 5).

Figure 5. Apply Loctite 8009 To Threads And Tapered Fingers Of Clinch Nut

2. Measure the distance from the bottom of the tank to the top of the manway as shown in Figure 6.

Minimum riser flange diameter recommended

for installation of all assemblies is 8” (203mm).

Assemblies may fit into a 6” (152mm) riser

flange if no fixed pressure relief is used. The

2HP or 3/4HP UMP will not fit through a 4”

(102mm) riser.

WARNING

8” minimum ID

bulk head diameter

Apply anti-sieze to clinch nut threads

and taper (if separated)

Loading...

Loading...