Installation Wiring Diagrams

17

SIMPLIFIED WIRING DIAGRAMS

Wiring Diagrams

SINGLE TANK INSTALLATIONS

Figure 16 through Figure 25 contain example wiring diagrams for various single tank/submersible DEF pump

installations.

MANIFOLDED TANK INSTALLATIONS

When greater flow rates are needed, two pumps may be installed in the same piping system by means of a

manifold.Tandem systems offer backup support so operations can continue if one pump stops working.

Figure 26 through Figure 29 contain example wiring diagrams for various manifolded tanks/submersible DEF

pump installations featuring Isotrol Control Boxes.

ISOTROL CONTROL BOX WIRING PRECAUTIONS (Apply to Figure 22 through Figure 29):

The Isotrol Control Box is intended to provide electrical isolation between the dispens-

er pump enable (Hook) signal and the submersible turbine pump (STP) control relay.

Other energized sources of power can still exist within the dispenser even with this

device. The neutral connection to the N terminal of TB1 and N terminal of TB2 must be

from the service panel and be a permanently connected, unswitched connection.

• The N connection on TB1 and the eight N connections on TB2 may be spliced to a common neutral

wire from the service panel described above.

• Make only one ‘wire’ connection on each N terminal on TB2.

The phase of L1 (TB1) must match the phase of the power supplying the ATG device to

prevent cross phasing which may damage the input on some ATG equipment.

GENERAL WIRING PRECAUTIONS

• Wiring must be rated 90°C minimum.

• Make ground connection in accordance with local codes.

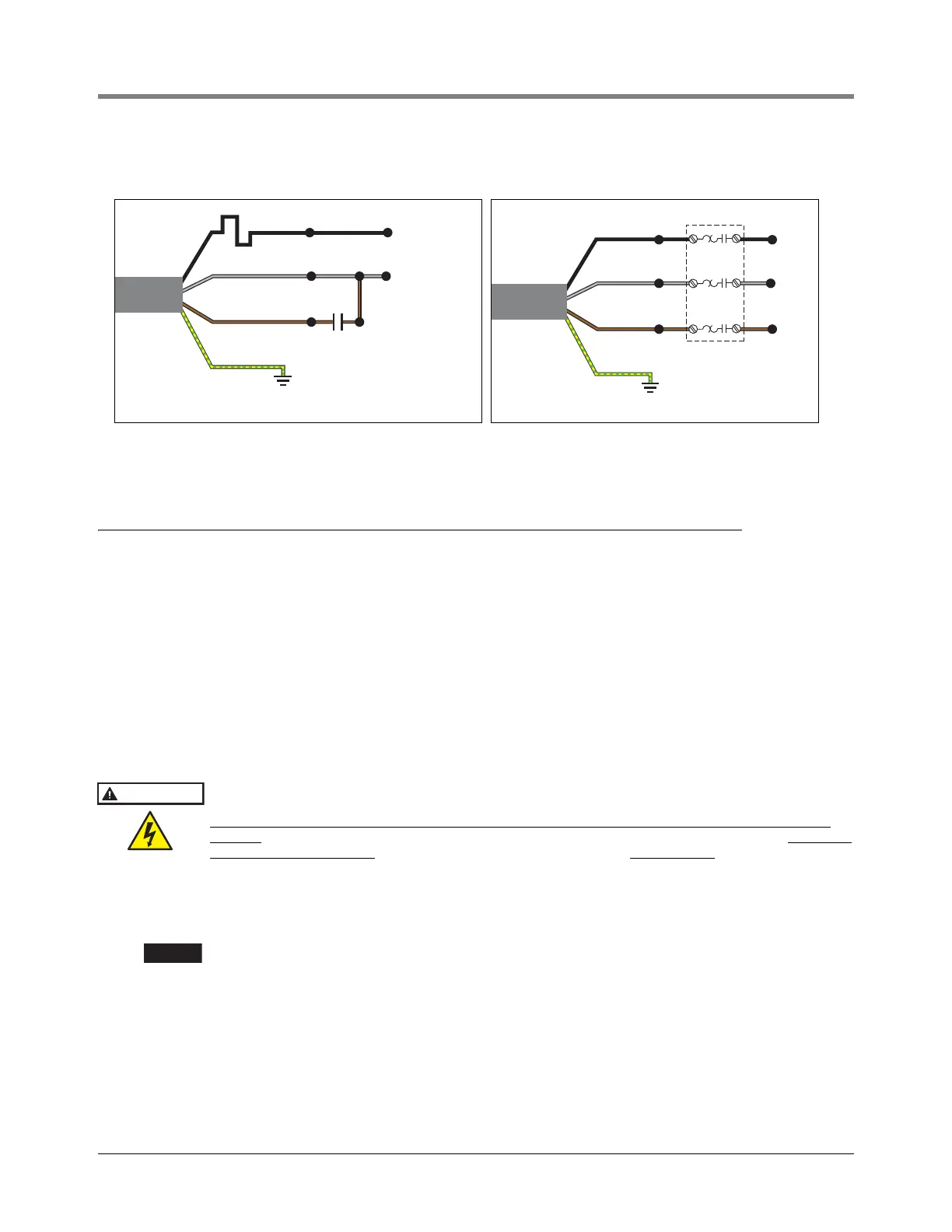

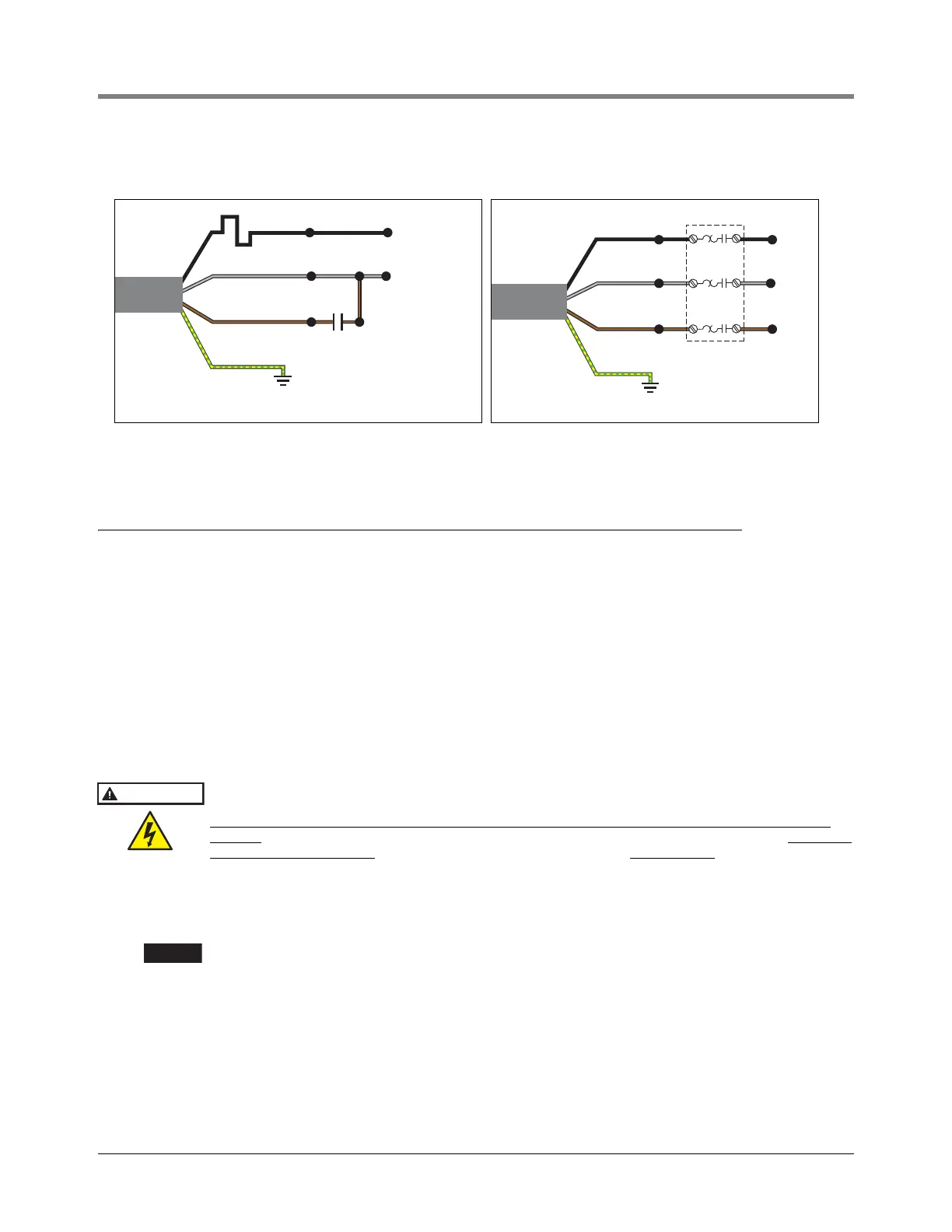

Figure 14. Single Phase Wiring Diagram Figure 15. Three Phase Wiring Diagram

Black

T

C

Grey

M2

M1

L2

L1

Brown

Yellow/Green

M3

M1 - Main

M2 - Common

M3 - Auxilliary

C - Capacitor

T - Thermal Device

Black

Grey

T3

T2

L3

L2

L1

Brown

Yellow/

Green

T1

Class 10

Starter With

Overloads

Loading...

Loading...