31

Troubleshooting

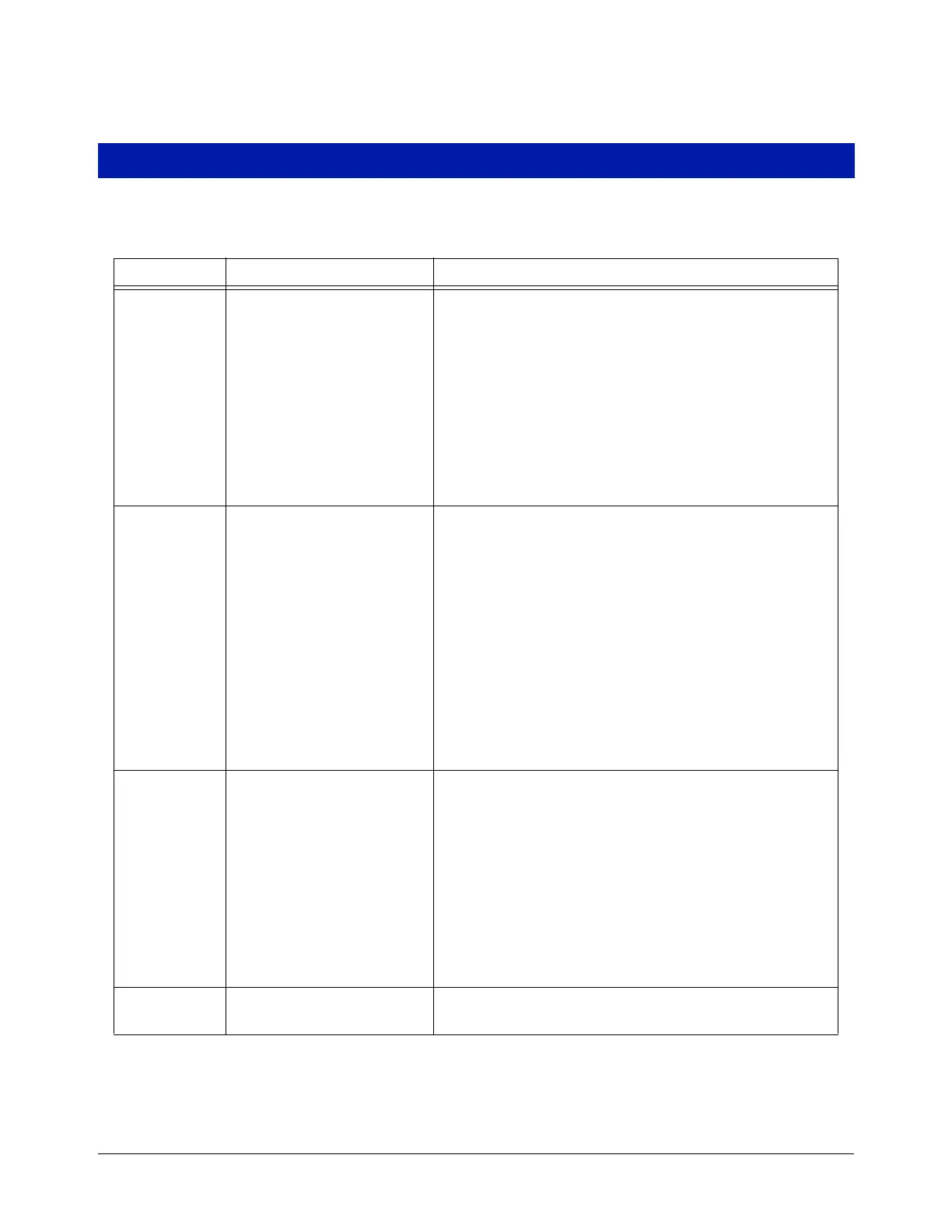

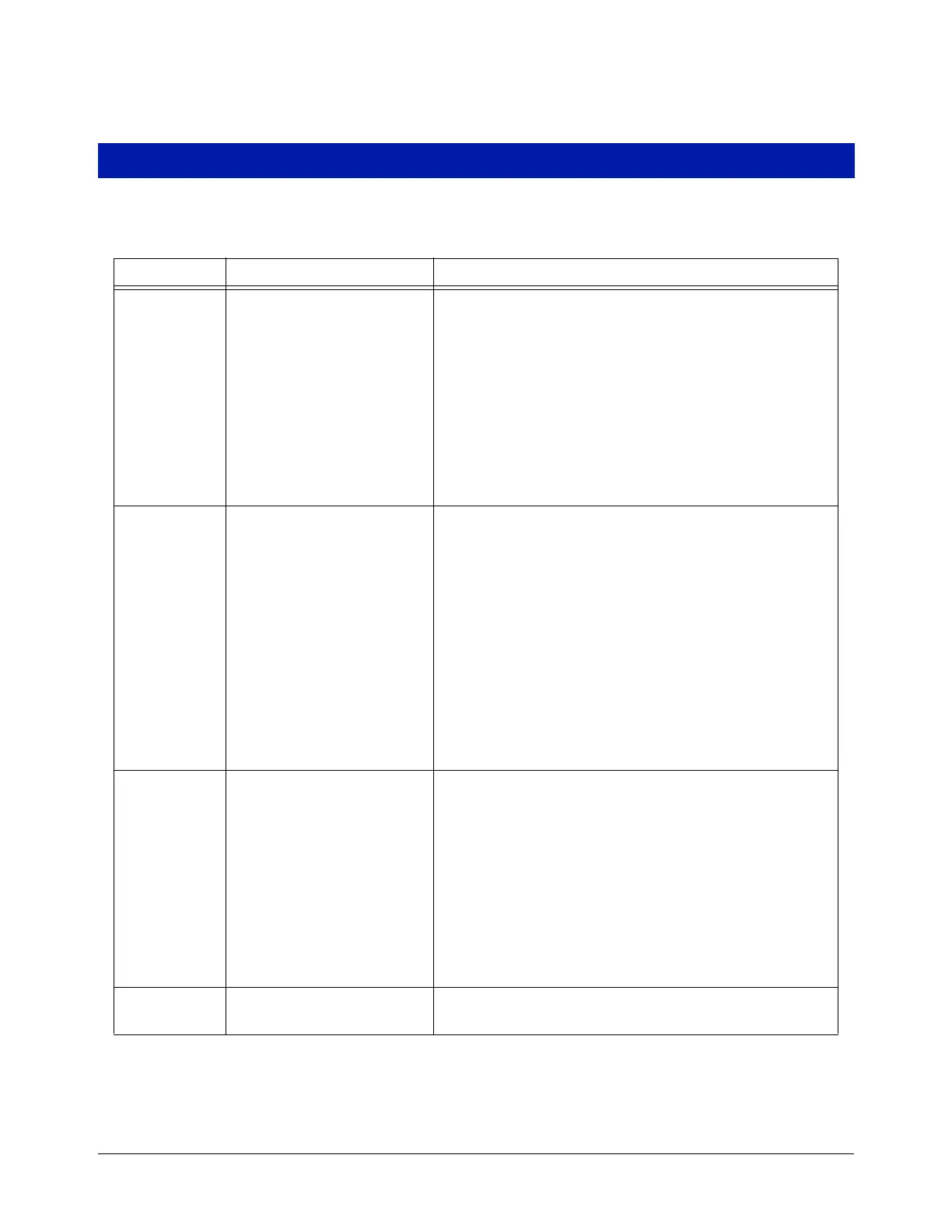

Table 2. Submersible DEF Pump System Troubleshooting

Trouble Cause Corrective Action

Pump stops

and starts

a. Incorrect voltage or volt-

age drop.

a. Check the voltage during starting. If the wiring cross-

section is too small, the voltage drop may be such that

the motor cannot function normally. Installation of a volt-

age boost transformer may be necessary.

b. Open circuit or incorrect

pump wiring.

b. Measure the resistance between pump wires. Check the

pump cable and all wiring to the pump and control boxes

is per the manuals.

c. Motor protection trips out. c. Confirm pump has bypass flow per manual require-

ments. For 3-phase pumps, verify the heaters in the

starter box are the correct size. For single phase pumps,

check capacitor for opens or shorts.

No product

flow

a. Pump is not running. a. See above.

b. Controller not powered. b. Check that the circuit breaker and lockout switch on

control box are not in the Off or tripped position.

c. Restriction in piping sys-

tem.

c. Confirm flow direction of check valve is correct. Confirm

ball valves and plumbing in sump is correct.

d. Insufficient DEF in tank. d. Check fluid level in tank, Confirm minimum of 6 inches

(150mm) above the pump strainer/inlet.

e. Frozen DEF in piping sys-

tem.

e. DEF freezes at +12°F (-11°C). Installation of pipe heat-

ers or a DEF recirculation system may be necessary.

f. Wrong direction of rotation

(single phase).

f. Interchange the two pump wires to the capacitor.

Insufficient

product flow

a. Bypass valve is set below

desired pressure.

a. Set bypass pressure per requirements stated in manual.

b. Strainer clogged. b. Confirm pump strainer is not clogged.

c. Wrong direction of rota-

tion (3 Phase).

c. Interchange two pump wires at box.

d. Fixed pressure relief is

stuck open.

d. Confirm fixed pressure relief valve is closed and sealed

before setting pressure (45 psi [310 kPa]).

e. Partially frozen DEF in pip-

ing system.

e. Continue to dispense DEF to thaw out piping.

Slow to dis-

charge DEF

a. Confirm system is holding

pressure.

a. Check pressure holding of system with pump off and

assure check valve does not have any contamination.

Loading...

Loading...