1

Introduction

Overview

The CoreDEF Series Submersible DEF Pump, herein referred to as Submersible DEF pump, is only intended to be

used to pump Diesel Exhaust Fluid (DEF) from underground storage tanks (UST) or above ground totes in retail,

commercial, and industrial applications. The submersible DEF pump installs into a threaded opening in the bulk

head with a minimum diameter of 8” (203mm) for clearance. The adjustable column pipe is available in a variety of

lengths to accommodate various tank diameters and designs.

The submersible DEF pump system is equipped with variable length column pipe, check valve, pressure relief kits,

optional pressure gauge and various UMP configurations. Operation in flammable fluids is not allowed. The

submersible DEF pump should only be used as described in this manual and is designed for DEF consisting of

32.5% urea and 67.5% de-ionized water.

The submersible DEF pump offers the following features:

• Liquid Quality Compliance - the pump and supplied components satisfy the ISO 22241 standard for DEF

quality.

• Continuous Run Capability - the pressure relief valve will allow the pump to run continuously regardless of

dispensing from the fueling nozzle. Fluid is recirculated back to the tank through the pressure relief valve.

• Start/Stop Capabilities - the pump and motor are capable of up to 30 motor/pump start and stops per hour

regardless of pump flow rates.

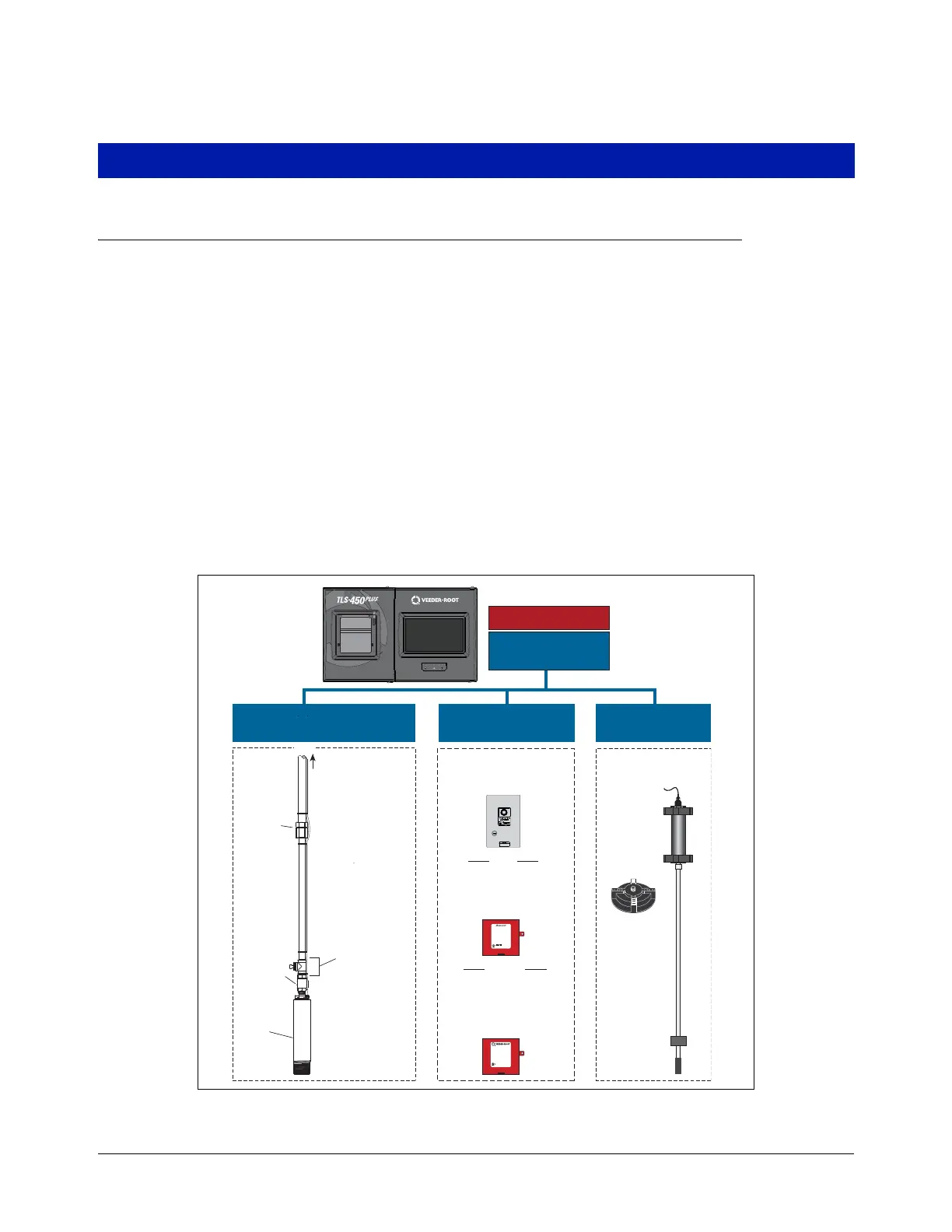

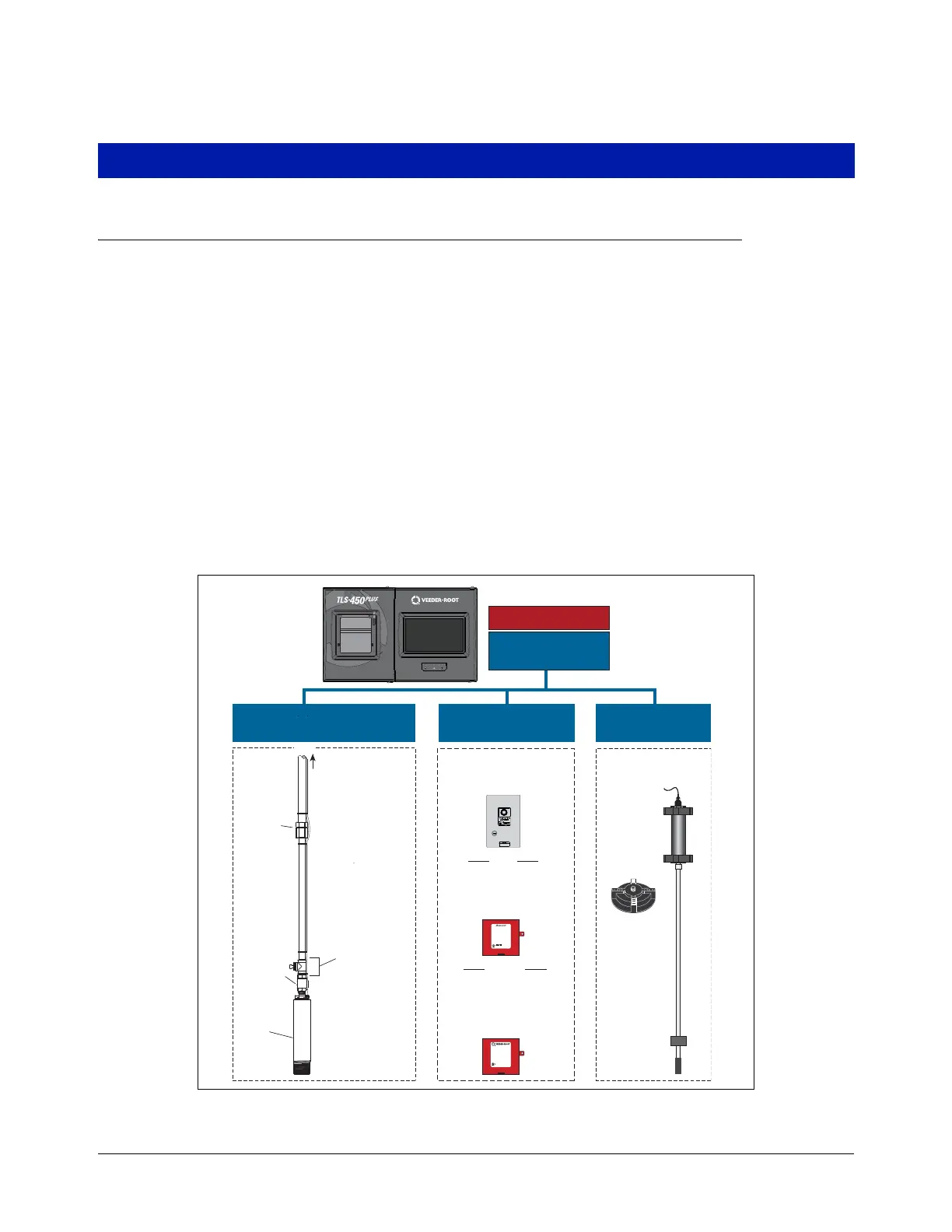

Figure 1. Typical Submersible DEF Pump System Components

ATG

(TLS-350 or TLS-4XX)

With Control Relay

Three Phase

Magnetic Starter

& 3 Heaters

DEF System Control

Submersible DEF Pump

Controllers

DEF Tank

Product Level

Monitoring

UMP

Riser Cap

S.S.Mag Probe W/

Alt. Fluids Float Kit

Check

Valve

Fixed

Bypass/Pressure

Relief Valve

Assembly

(Optionally -

In Sump)

Clinch

Fitting

To Manway

Submersible

DEF

Pump

OR

AND

For Multiple

Dispenser Applications

Single Phase

Control Box

W/Capacitor

VEEDER-ROOT CO.

2709 RTE 764

DUNCANSVILE, PA 16635

INDUSTRIAL CONTROL EQUIPMENT - ENCLOSED (TYPE 1)

INSTALL IN NON-HAZARDOUS LOCATION

NE PAS INSTALLER DANS LES EMPLACEMENTS DANGEREUX

3 WIRE, 120/240 VOLTS AC, 1 PH. 50/60 Hz 2 HP MAX.

AUTOMATIC RESET OVERLOAD IN MOTOR

PART NO. 880-045-5; CONTAINS 17.5 MFD. CAPACITOR

DISPENSER INPUT RATING 120V 30 mA

PART NO. 880-046-5; CONTAINS 25 MFD. CAPACITOR

DISPENSER INPUT RATING 120V 30 mA

PART NO. 410861-001; CONTAINS 40 MFD. CAPACITOR

DISPENSER INPUT RATING 120V 30 mA

THIS DEVICE HAS MORE THAN ONE

POWER SUPPLY CONNECTION POINT. DISCONNECT

ALL POWER SUPPLIES BEFORE SERVICING.

511L

+

+

+

410865-001

Isotrol

Control Box

46NN

ISOTROL

TM

1-8R CONTROL BOX

PART No. 880-047

WITH DISPENSER HOOK SIGNAL ISOLATION

INSTALL IN NON-HAZARDOUS LOCATION

3 WIRE 240 VOLTS AC, 50/60 Hz

DISPENSER INPUT RATING 120V 15mA

ATG OUTPUT RATING 120V 750mA

CONTROL CIRCUIT RATING120V 765mA

RELAY RATED 2HP, 1PH, 240V, 50/60 Hz

S INPUT (RELAY COIL) RATED 120V 60mA

AUTOMATIC RESET OVERLOAD IN MOTOR

CIRCUITS ARE ENERGIZED WHEN INDICATOR IS ON

CAUTION: THIS DEVICE HAS MORE THAN ONE POWER

SUPPLY CONNECTION POINT. DISCONNECT ALL POWER

SUPPLIES BEFORE SERVICING.

CONTROL CONSOLE INTERCONNECTION BOX

Loading...

Loading...