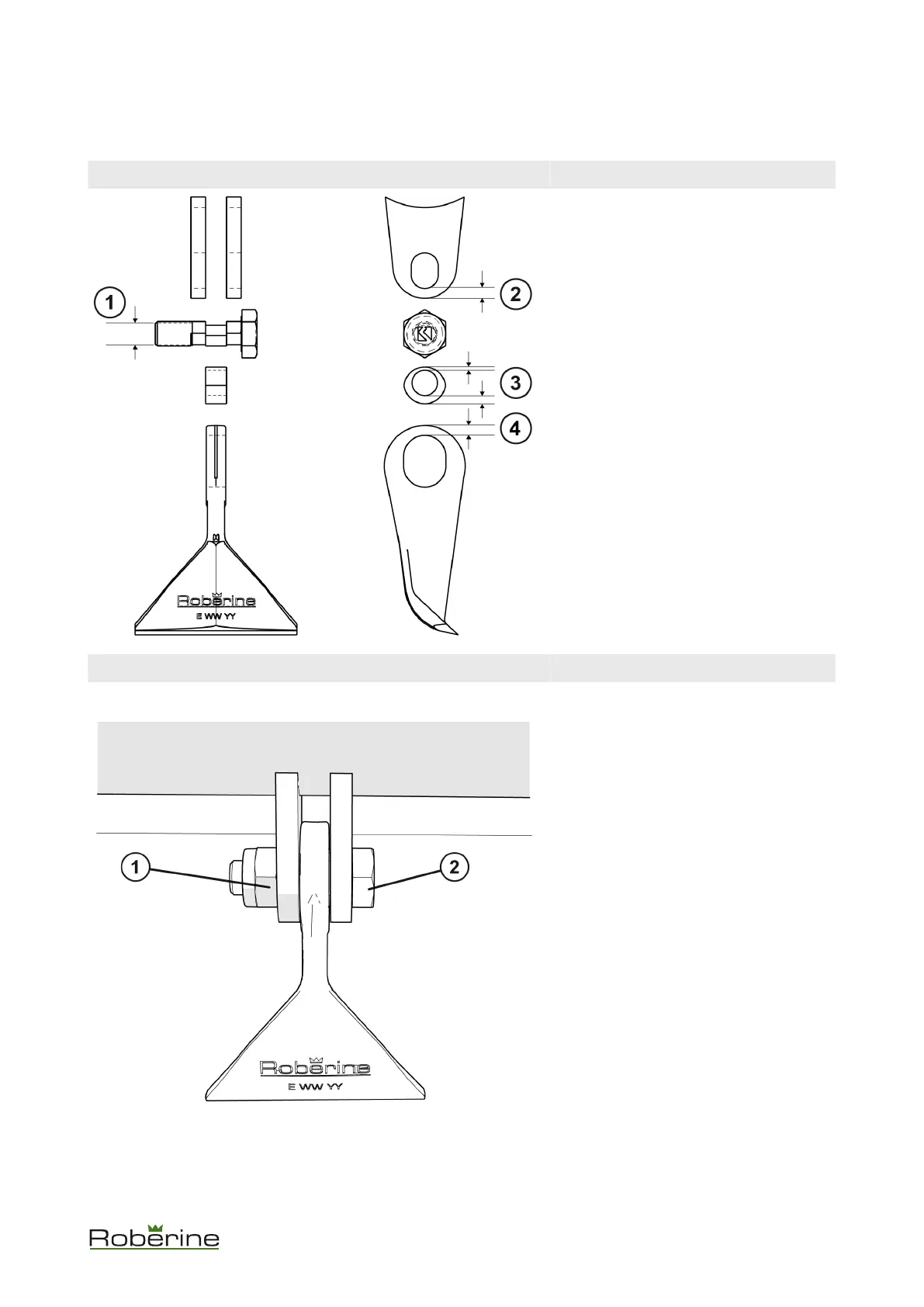

8.14 Checking and replacing the flails

If the flails are lost, damaged or worn too much, they must be replaced to prevent damage to the rotor shaft due to

imbalance.

Maximum flail wear

Minimum value:

1. 8 mm

2. 4.5 mm

3. 0.5 mm

4. 4 mm

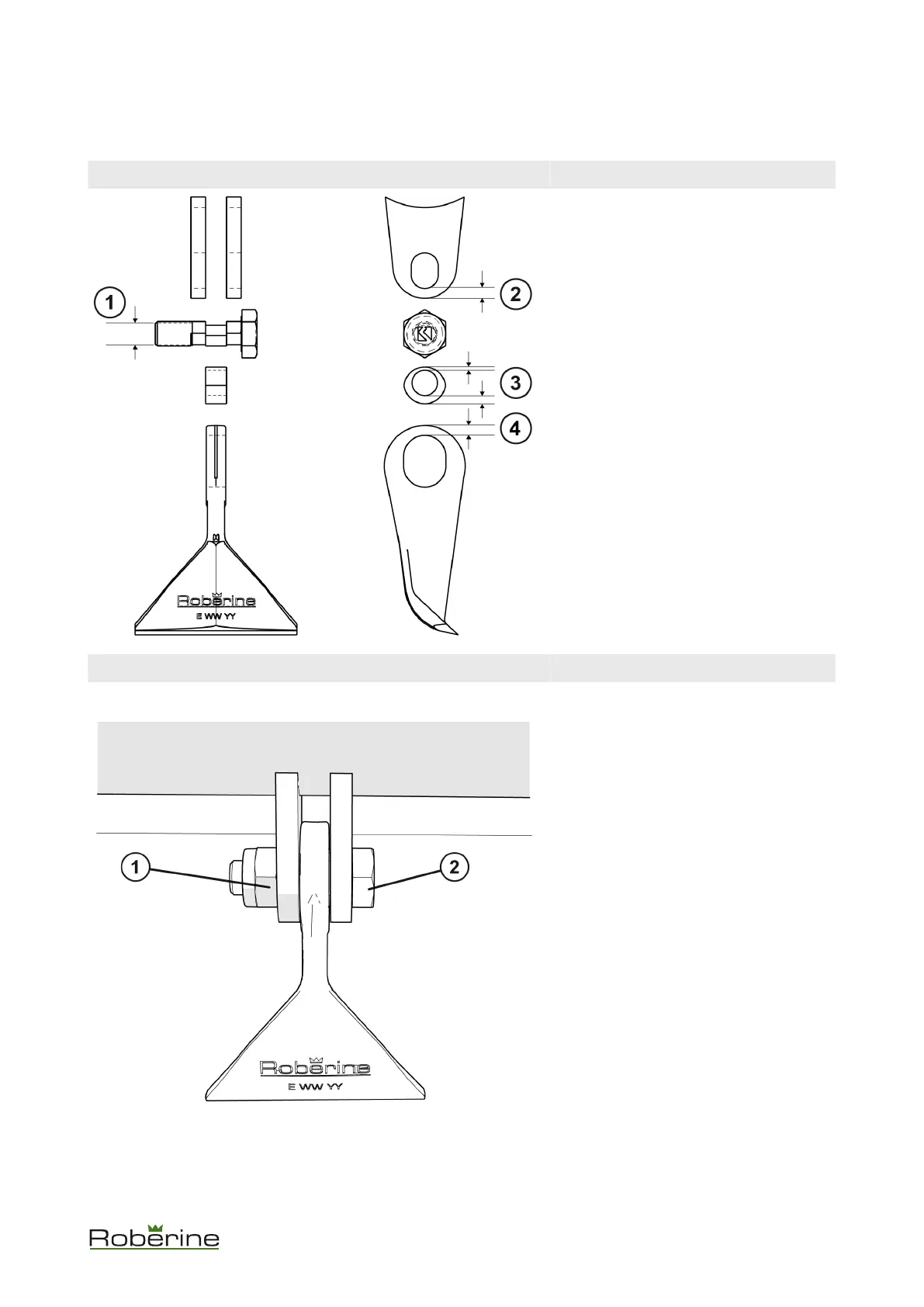

Replacing the flails

Before you begin: Park the machine safely and let the engine cool down.

1. Remove the nut (1).

2. Remove the flail bolt (2).

3. Remove the flail and replace it with a

new one.

4. Install the flail bolt (2). Replace worn flail

bolts and bushings if required.

5. Install the nut (1) and tighten it to a

torque of 48 Nm.

Maintenance 50

Loading...

Loading...