43

7 TROUBLESHOOTING

In this paragraph are reported the common problems of SENTINEL operation, for the Blower problems

please refer always to the blower manual.

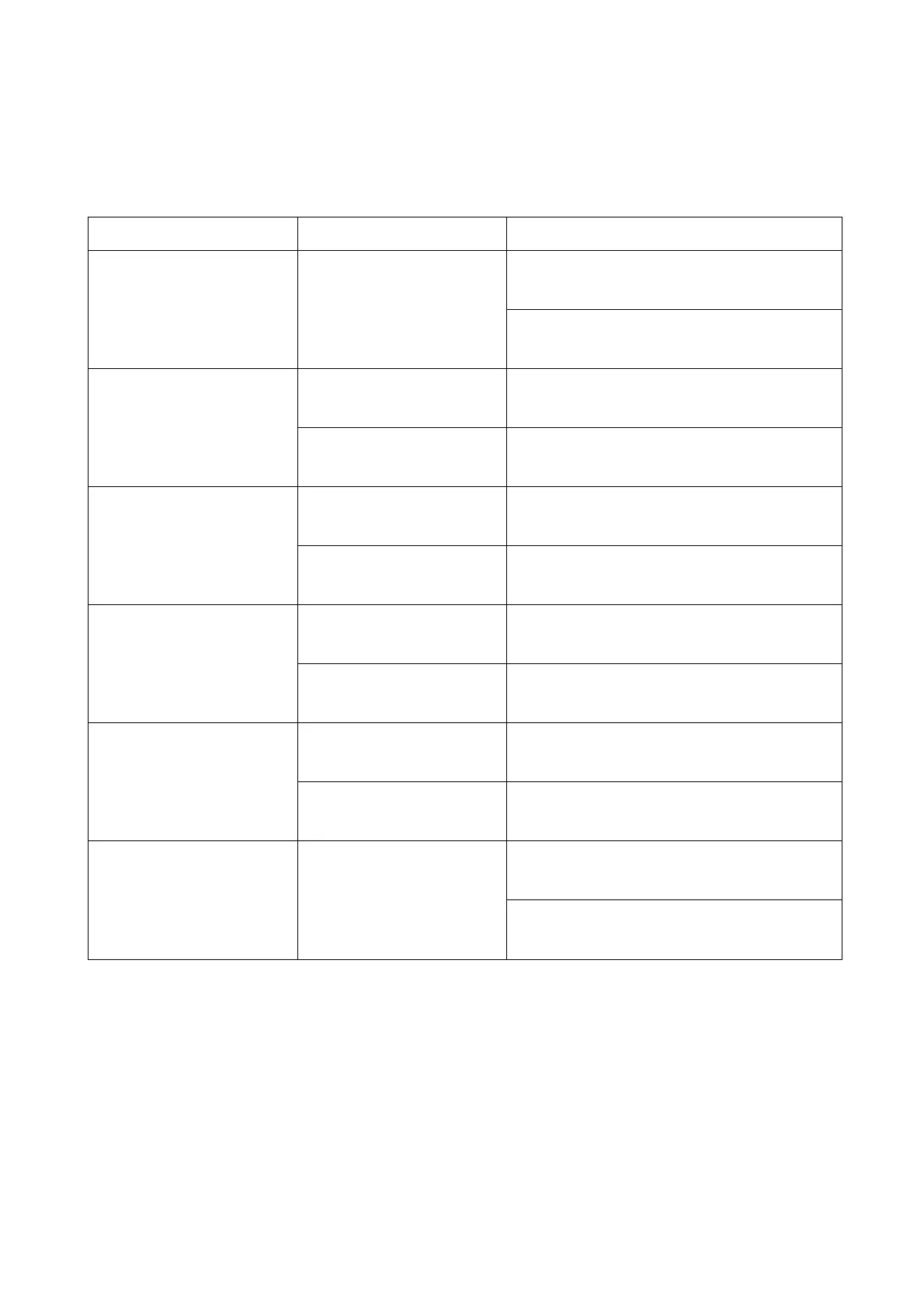

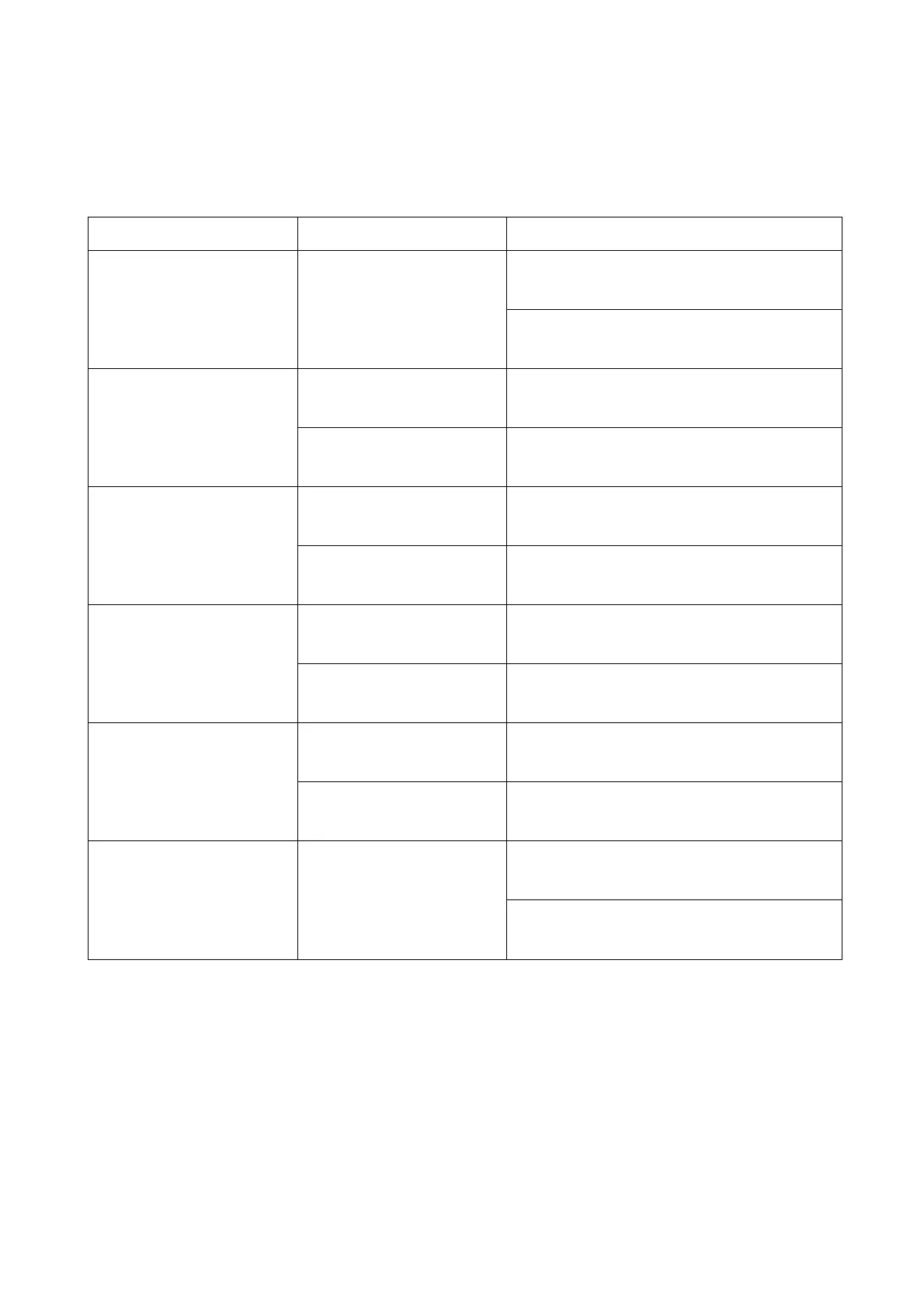

Problem Cause Remedies

SENTINEL not switch on No electrical supply

Check the electric supply from the starting

panel

Change the SENTINEL fuse

The display visualizes

P1=-0000mBar

P1 pressure hose not

connected or cut

Verify P1 pressure hose connection to

SENTINEL and to the blower or eventually

change it

P1 pressure hose connected

to P2

Verify the connection and restore it

The display visualizes

P2=atmospheric pressure

P2 pressure hose not

connected or cut

Verify P2 pressure hose connection to

SENTINEL and to the blower or eventually

change it

P2 pressure hose connected

to P1

Verify the connection and restore it

SENTINEL stops always the

blower for an high

temperature

Temperature transducer not

connected

Verify the transducer connection

Temperature transducer

damaged

Change the transducer

SENTINEL stops always the

blower and visualizes the

message

<->

Wrong rotational direction Check the motor electrical supply

Speed transducer damaged

Verify the connection and the continuity of the

cables

SENTINEL stops always the

blower and visualizes the

message

NO OIL

But there is oil

Oil level transducers

damaged

Check the connection of the oil level

transducer with SENTINEL

Change the transducers

Loading...

Loading...