Rockwell Automation Publication 750-QS100B-EN-P - August 2020 15

Step 3: Power Up, Configure the Modular Control Profiles

Preparation

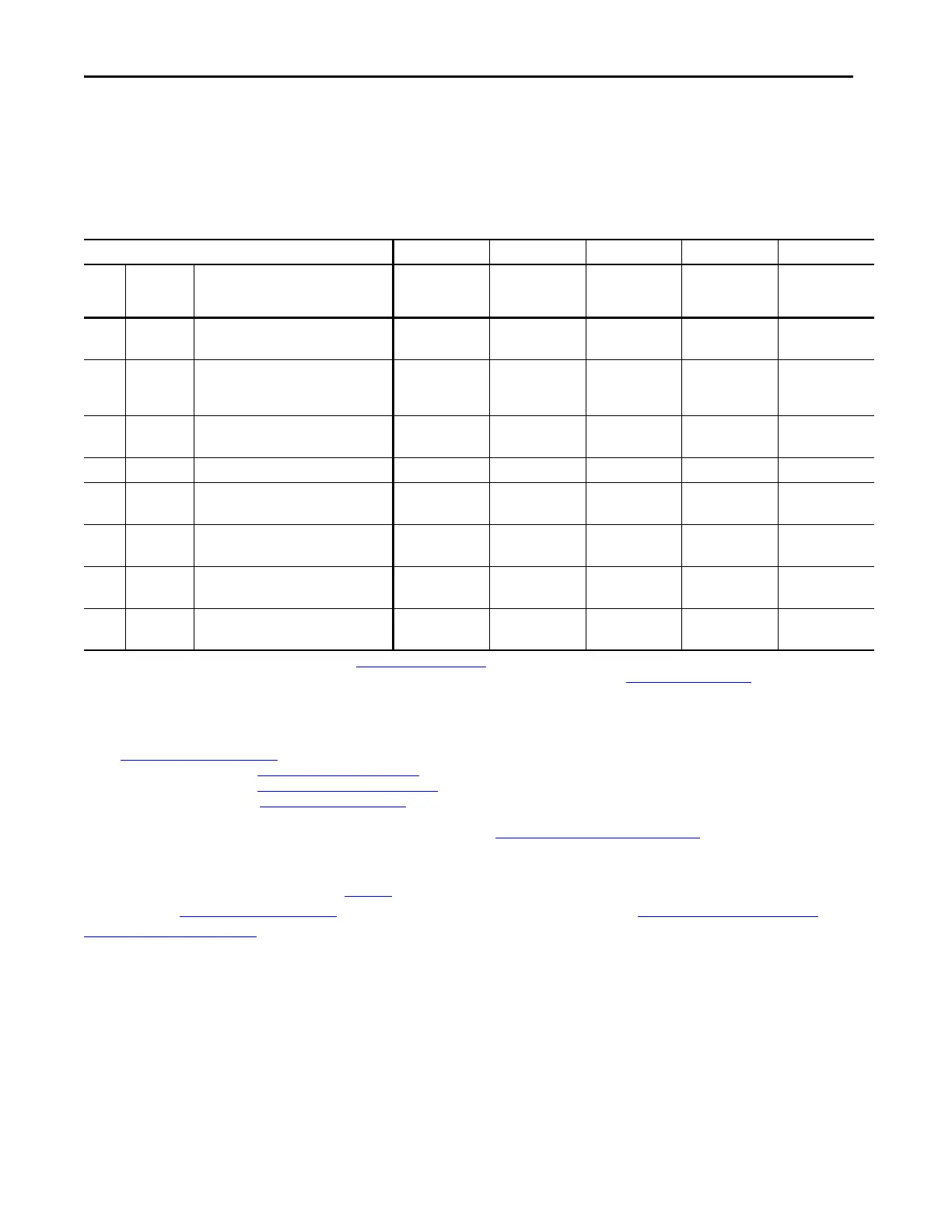

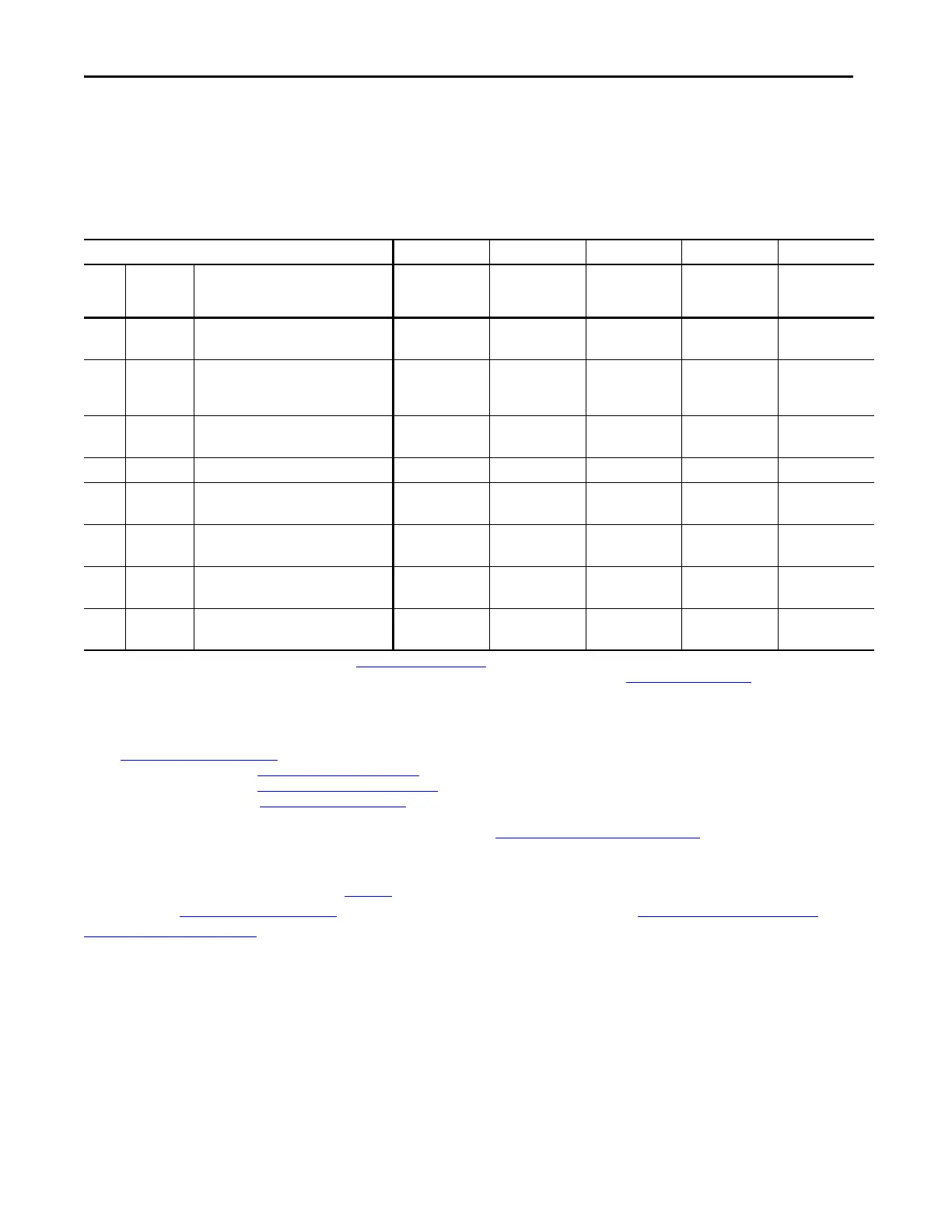

Use the following table to record your configurations and preferences. See the detailed description below the table for

more information about what to record in this table.

Table 3 - Configurations and Preferences

Some of the parameters that are listed in Ta b l e 3 require you to reset the device to change the value of the parameter. See

Appendix A > Reset Device on page 53

. The parameters that require reset are listed in Reset Device and Verify the

Configurations on page 25.

Drive/Motor Name (example, Main Exhaust Fan)

Port

No.

Related

Parameter

No.

Description Drive/Motor 1: Drive/Motor 2: Drive/Motor 3: Drive/Motor 4: Drive/Motor 5:

033 Voltage Class

(1)

(Low, High)

035 Duty Rating Class

(2)

(Light Duty [LD], Normal Duty [ND], Heavy

Duty [HD])

0 46 Velocity Units

(Hertz, RPM)

0 65 Primary Motor Control Mode

(3)

0 70 Application Select

(4)

(None, PID, Torque Prove, OilWell Pump)

0 72 Embedded Logic Select

(5)

(None, DeviceLogix™)

10 110 Stop Mode

(6)

(Coast, Ramp, Current Limit, Decel Hold)

10 116 Motor Side DC Bus Regulation Mode

(7)

(Disabled, Adjust Frequency)

(1) Low for 400V and 600V drives. High for 480V and 690V drives. See Enter the Voltage Class on page 20 for more information about this setting.

(2) Depends on the application overload requirements. LD = 110% for 60 s, ND = 110%/150% for 60 s/3 s, HD = 150%/180% for 60 s/3 s. See Enter the Duty Rating on page 21

for more information about this

setting.

(3) Motor control mode options include: Induction Volts Per Hertz, Induction Sensorless Vector, Induction Economizer, Induction Flux Vector, Interior Permanent Magnet Flux Vector, Surface Permanent Magnet

Flux Vector, Permanent Magnet Volts Per Hertz, Permanent Magnet Sensorless Vector, Synchronous Reluctance Volts Per Hertz, and Synchronous Reluctance Sensorless Vector. For most applications, select

an SV (Sensorless Vector) or Econ (Econ SV) motor control mode. If your application requires closed loop velocity control with encoder feedback, select an FV (Flux Vector) motor control mode.

See Enter the Motor Control Mode on page 22

for more information about this setting.

(4) For most applications, select ‘None‘. See Enter the Application Selection on page 23

for more information about this setting.

(5) For most applications, select ‘None’. See Enter the Embedded Logic Selection on page 23

for more information about this setting.

(6) For most applications, select ‘Ramp’. See Enter the Motor Stop Mode on page 24

for more information about this setting. If parameter 0:65 (port 0, parameter 65) is changed, then performing a Reset

Device procedure changes parameters that are associated with port 10.

(7) For PowerFlex 755TL drives, select ‘Adjust Frequency’. For PowerFlex 755TR drives, select ‘Disabled’. See Enter the Motor Side Bus Regulation Mode on page 25

for more information about this setting. If

parameter 0:65 is changed, then performing a Reset Device procedure changes parameters that are associated with port 10.

Loading...

Loading...