38 Publication 2100-IN012C-EN-P - April 2009

Chapter 2 Installation Procedures

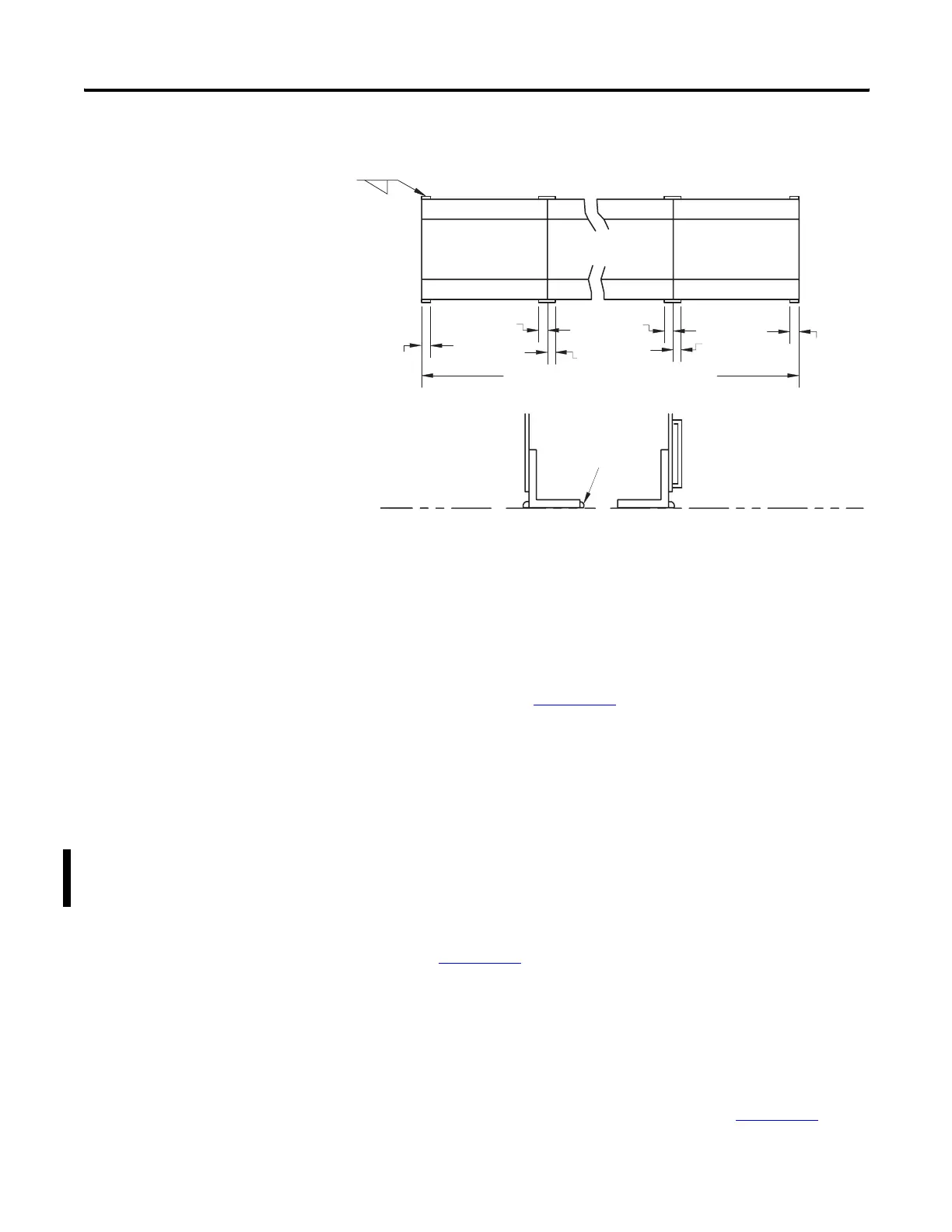

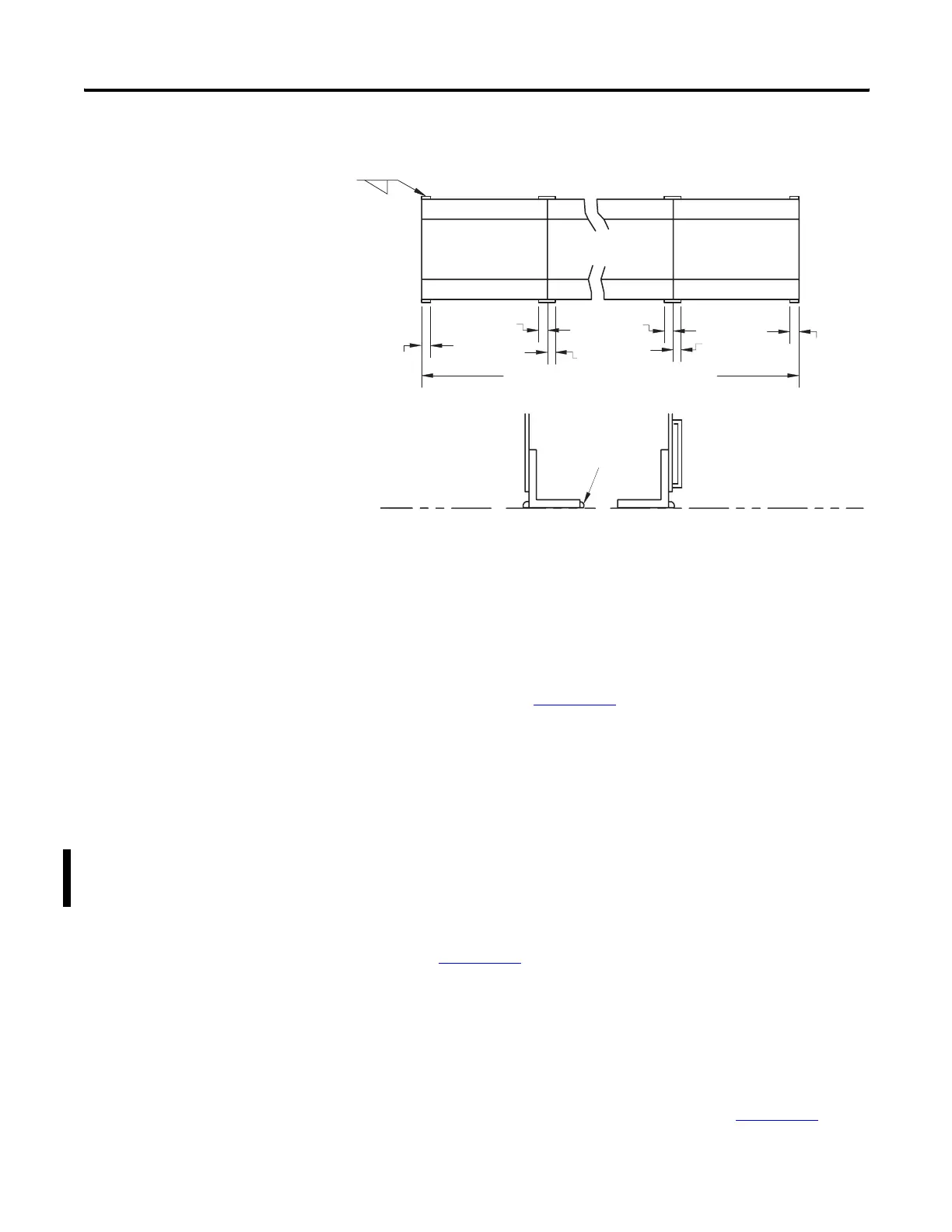

Seismic Weld Down Requirements

Joining & Splicing New

MCCs

A main horizontal bus splice kit must be installed between shipping

blocks of new MCCs to connect the main horizontal bus. In addition,

the neutral bus splice kit (if required) and the ground bus splice kit

must be installed between shipping blocks. Refer to CENTERLINE

2100 Motor Control Centers Joining & Splicing Vertical Sections

Instructions, publication 2100-IN010

.

Joining & Splicing Existing

MCCs

A main horizontal bus, a neutral bus (if required), and a ground bus

splice kit must be installed when adding to existing CENTERLINE

MCCs. When adding to existing MCCs, you must identify the series of

the MCC that you will be adding to. If the existing MCC is series A or

B, you must consult MCC technical support at 1.440.646.5800 and

follow the prompts to Allen-Bradley>Low Voltage Motor Control

Centers>Post Shipment Support for joining and splicing procedures.

When the existing MCC is series C or later, refer to CENTERLINE 2100

Motor Control Centers Joining & Splicing Vertical Sections Instructions,

publication 2100-IN010

.

Be sure to also connect DeviceNet cables and other control cables as

required.

Installing and Joining Pull

Boxes

When pull boxes are supplied with your MCC, refer to Installing a Pull

Box on a Bulletin 2100 Vertical Section, publication 2100-IN029

, for

installing and joining the pull box onto the vertical section.

0.25 in. (6 mm)

1.50 in. (38 mm)

1.50 in.

(38 mm)

1.50 in. (38 mm)

1.50 in. (38 mm)

1.50 in. (38 mm)

1.50 in.

(38 mm)

Rear

Front

First Section Last Section

Second Section and

Additional Sections

MCC Lineup

Rear

Front

Optional Location

for Rear Welds

Floor Line

Left-hand Side View

Loading...

Loading...