Publication 2100-IN012C-EN-P - April 2009 39

Installation Procedures Chapter 2

Joining and Splicing NEMA

Type 12 MCCs

NEMA Type 12 MCCs must be properly installed to prevent the ingress

of dust and dirt. Follow the caulking instructions in the NEMA Type 12

Sealing Instructions, publication 2100-IN037

, supplied with the NEMA

12 MCC. Using caulk, close any mounting holes in the bottom plates

and bolt holes between shipping splits.

It is necessary that all door latches and wireway doors be fully latched

to prevent dust and dirt from entering the enclosure and to meet

NEMA Type 12 requirements.

Joining & Splicing NEMA

Type 3R and Type 4 MCCs

A main horizontal bus, a neutral bus (if required) and a ground bus

splice kit must be installed between the internal sections for new and

existing NEMA Type 3R and Type 4 MCCs. Refer to CENTERLINE 2100

Motor Control Centers Joining & Splicing Vertical Sections Instructions,

publication 2100-IN010

, for splicing Type 3R and Type 4 internal

sections.

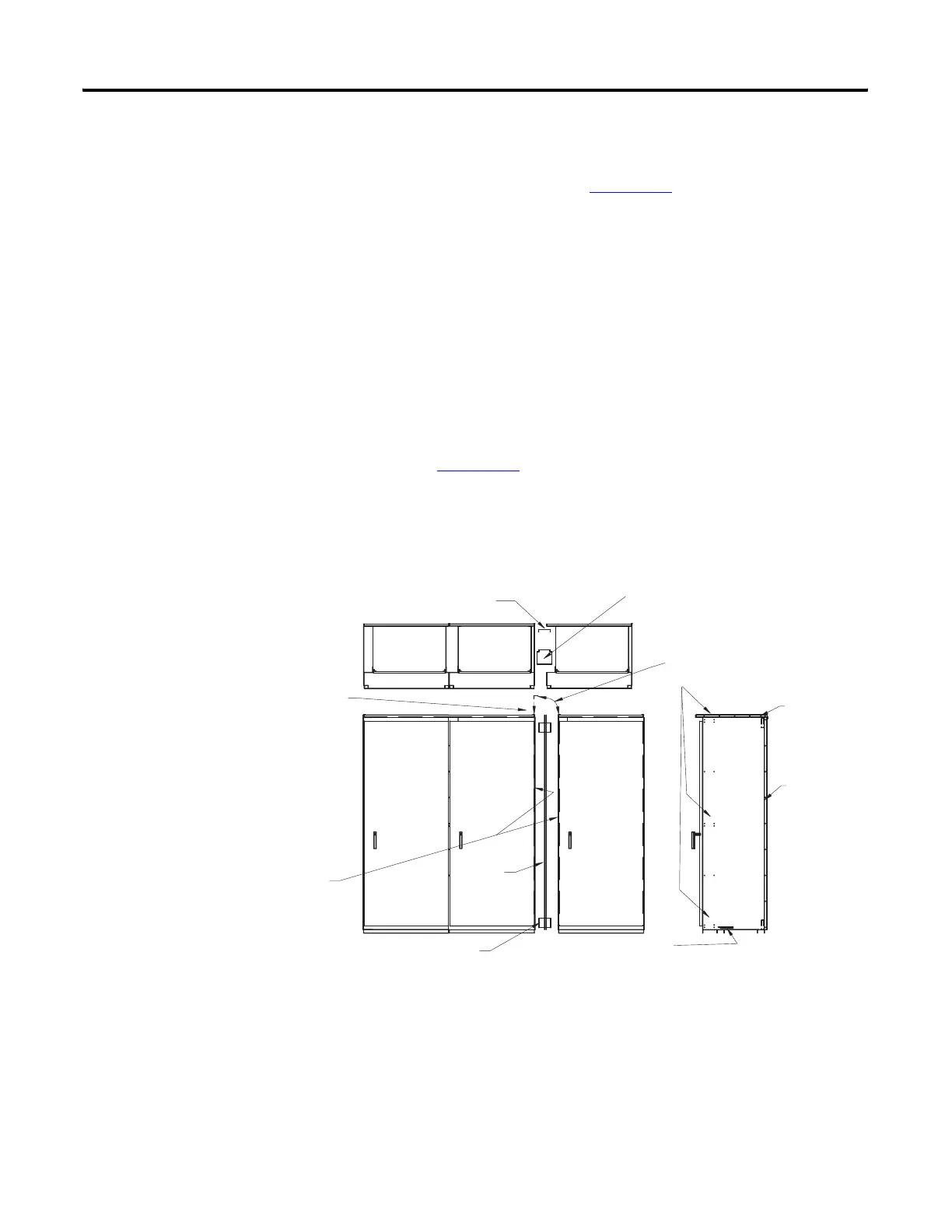

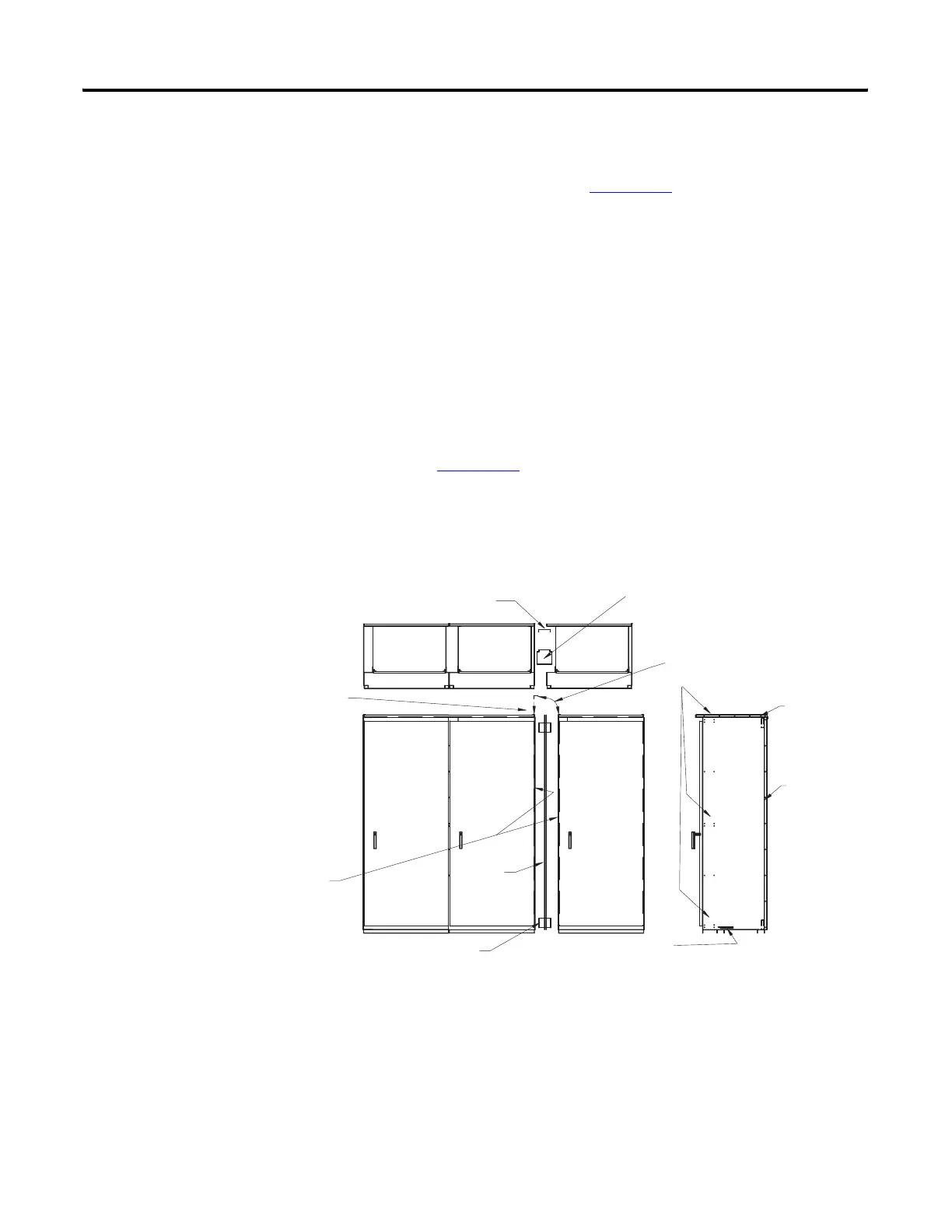

Joining Instructions for NEMA Type 3R and 4 Sections

MCC MCC MCC

Cabinet Spacer

(2) 0.25 in. (6 mm) x 0.50 in. (12.7 mm) Taptites

Cabinet Spacer

(2) 0.25 in. (6 mm) x 0.50 in.

(12.7 mm) Taptites

(2) 0.25 in. (6 mm) x 0.50 in. (12.7 mm) Taptit

Cabinet Spacer

(2) 0.25 in. (6 mm)

0.50 in. (12.7 mm)

Taptites

Gasket

Gasket

Wireway Extensions

(2) or (4) 0.25 in. (6 mm) x 0.50 in.

(12.7 mm) Taptites

(2) wireway extensions required for 15 in. (381 mm) deep.

(2) wireway extensions required for 20 in. (508 mm) deep.

(1) 0.25 in. (6 mm) -20 x 0.70 in. (17.78 mm) taptite per wireway extension.

Remove left-hand driphood angle and remount

after the adjacent driphood has been drilled out.

Remove right-hand driphood angle and

discard. Drill out (5) 0.172 in. (4.36

mm) diameter holes to 0.25 in. (6 mm)

diameter in driphood.

Remove the right-hand and

left-hand side plates before joining

sections. The gasket is across the

top of the driphood and down the

backplate on one of the adjoining

sections.

Gasket

Loading...

Loading...