Publication 2100-IN012C-EN-P - April 2009 45

Installing Conduit and Cable Chapter 3

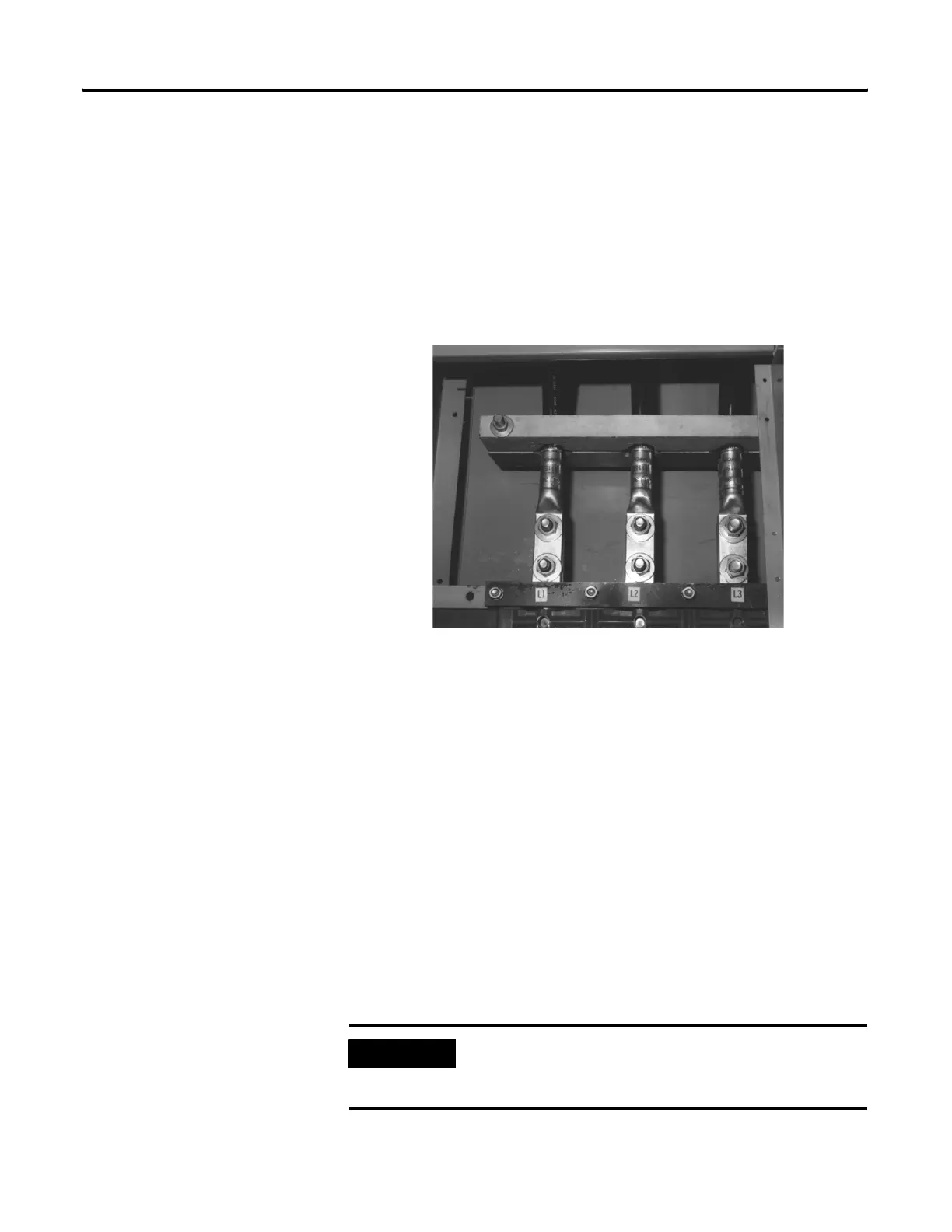

Securing Cables with Hardwood

In this example, a hardwood brace (maple hardwood) made for the

specific application is used. Holes are bored approximately the size of

the cable diameter. Several bolt holes are also bored the breadth of

the hardwood brace. The brace is cut in two pieces and is used as a

clamp to secure the cables. Through bolts are inserted into the brace

and tightened so that cables are held tightly in place.

Securing Cables with Hardwood

A second form of hardwood brace (not shown) is a yolk type in

which the cables are passed through. Holes should be small enough

to provide a snug fit for the cables. The connectors or lugs are

attached to the cables and cables are bolted to the terminals.

When using the hardwood bracing method and the short circuit

current is less then 42,000 A, cables should be braced every 12 in.

(305 mm). When the short circuit current is 42,000 A or greater, cables

should be braced every 6 in. (153 mm).

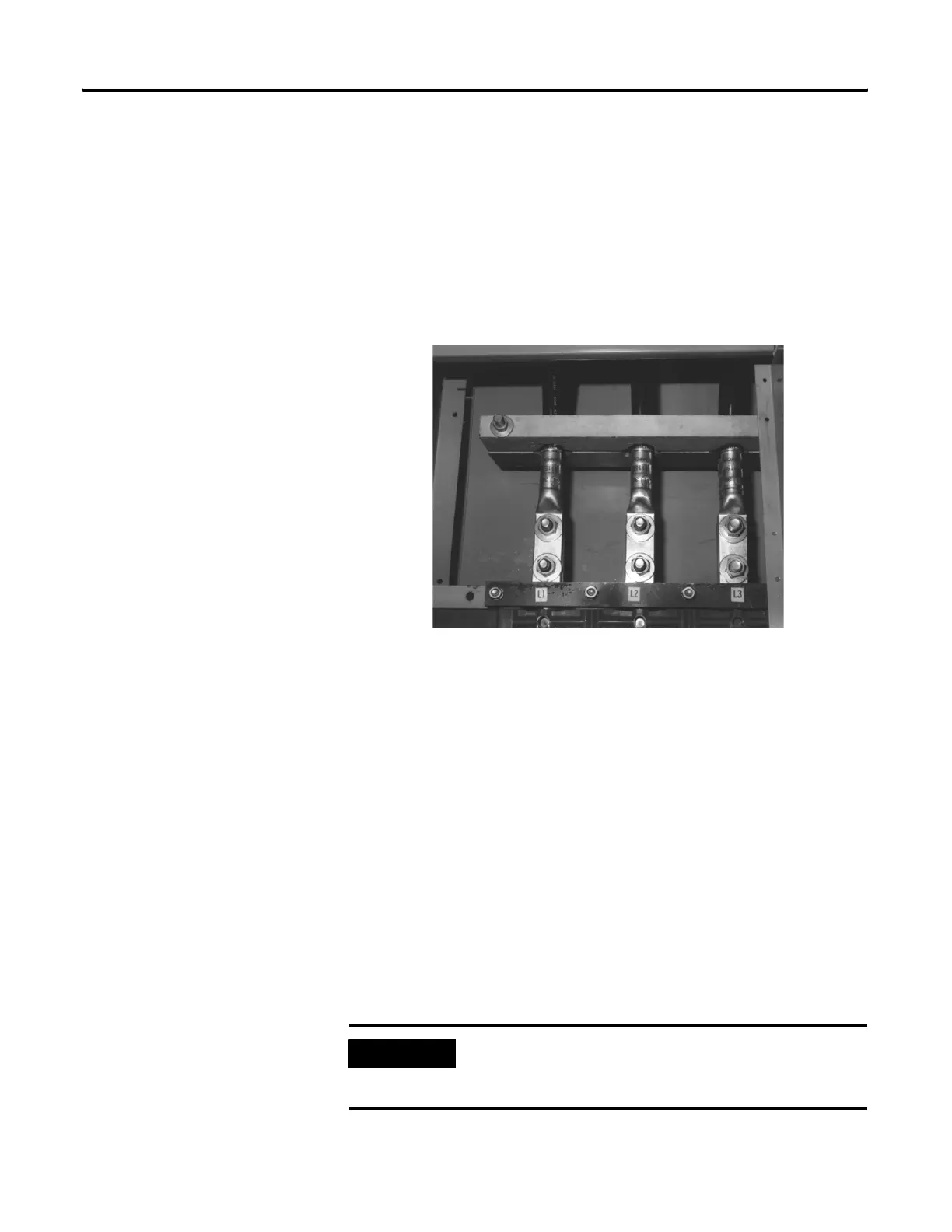

Incoming Line Brace

Allen-Bradley manufactures an incoming line brace similar to the

hardwood clamping-type brace. To order an incoming line brace,

contact your local Allen-Bradley sales office and reference assembly

number 40113–848.

IMPORTANT

Lugs should be installed so they are in line with each other and

proper spacing is used between phases. Hardware must be

torqued per the torque tables found on the enclosure door.

Loading...

Loading...