96 Publication 2100-IN012C-EN-P - April 2009

Chapter 9 Maintenance

1. Use test equipment to determine the temperature differential

and the temperature rise of accessible components within the

unit.

2. Determine the services and repair recommendations based on

the temperature category in the following guidance chart.

Inspect the Units for Signs of Overheating

1. If there are no signs of overheating and thermal infrared tests

indicate service is not necessary, document the units as

acceptable.

Use this information for reviewing the mean time to

maintenance for preventative maintenance for the specific

facility.

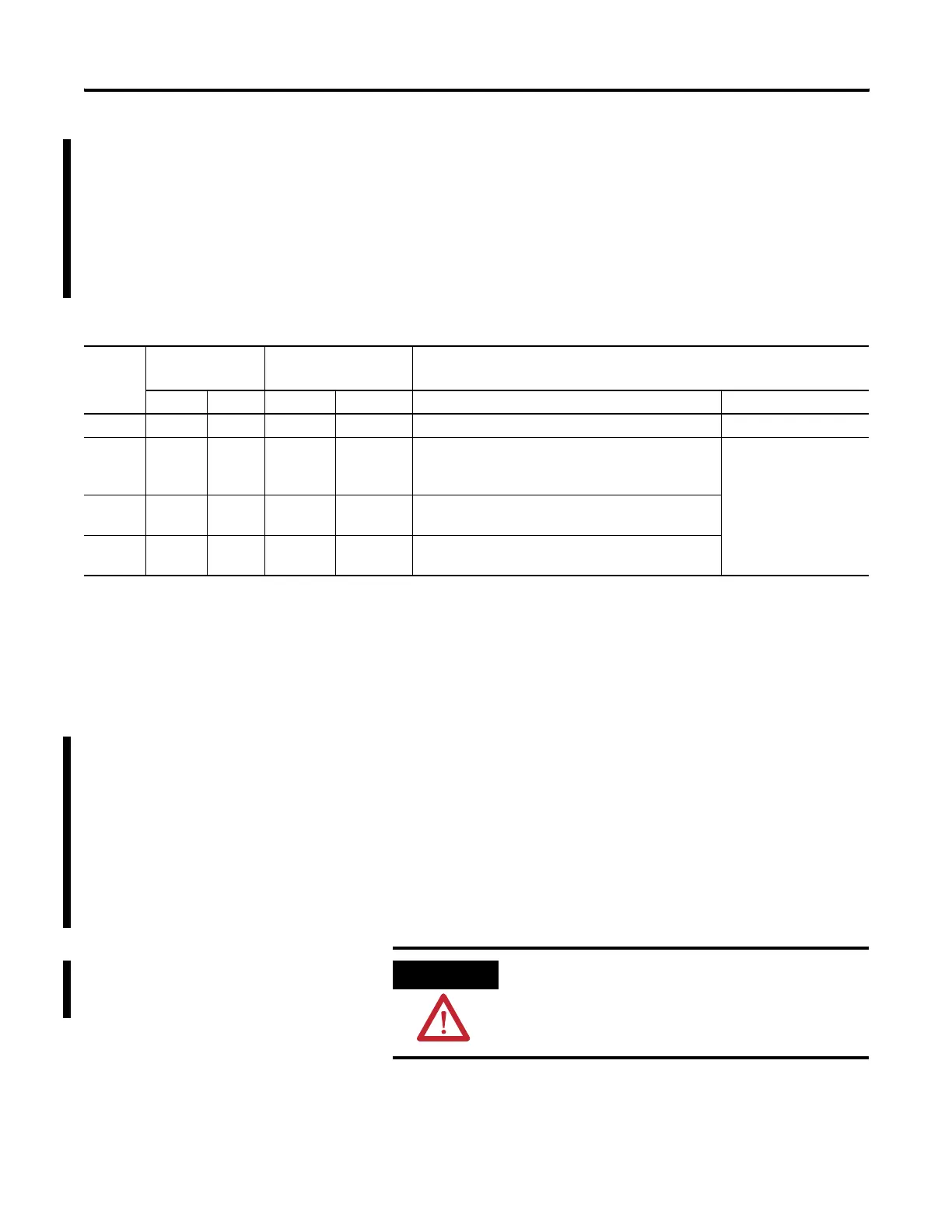

Temperature Guidance

Category Temperature

Differential

(1)

Temperature

Rise

(2)

Repair/Service

°C °F °C °F Service Interval Recommended Action

1 < 10° < 18° < 70° < 126° No service or repair required. See step 1 below.

2 10°...25° 18°...45° 70°...100° 126°...180° Service or repair the unit at next maintenance

schedule (not greater than six months but continue

monitoring as a part of preventive maintenance.)

See step 2 below.

3 25°...50° 45°...90° 100°...115° 180°...207° Service or repair the unit within the next two weeks

and monitor the unit at the next maintenance interval.

4 > 50° > 90° > 115° > 207° Shutdown the unit and repair. Verify that the

temperature is reduced after re-energization.

(1)

Temperature (measured or rise) differential between adjacent phases or like elements. Load between phases must be balanced with a normal variation not exceeding

seven percent.

(2)

Measured temperature less ambient.

Due to difficulty obtaining accurate infrared temperature measurements from highly reflective surfaces, we recommend using temperature differential readings in

determining the Service/Repair guidelines, for example, emissivity of tin or silver plated material.

ATTENTION

To service the units, make sure that the MCC remote

power sources are disconnected and that the respective

disconnects are locked in the OFF/O position.

Loading...

Loading...