Publication 2100-IN012C-EN-P - April 2009 37

Installation Procedures Chapter 2

Seismic Requirements

To demonstrate the seismic withstand of various CENTERLINE MCCs

[20 in. deep (508 mm), 30 in. deep (762 mm) back-to-back, and 40 in.

deep (1016 mm) back-to-back], the MCC design construction has been

qualified by seismic calculations per the Uniform Building Code

(UBC). CENTERLINE 2100 MCC samples have been seismically

qualified by dynamic (triaxial multi-frequency testing) seismic tests per

IEEE 344 Seismic Test Standards. The results of the MCC seismic

testing demonstrated compliance with the 100% g level of Uniform

Building Code 1997 (UBC) zone 4 (the maximum UBC zone) and

100% g level of The International Building Code 2006 (IBC), for

example, the MCC structure, the MCC units, and the MCC components

or electrical functions were not compromised when subjected to a

UBC Zone 4 earthquake, or the IBC seismic event. Per the IEEE 344

standard, the equipment was under power and operated before,

during, and after the seismic tests.

In order to obtain a UBC or IBC seismic withstandability, each

individual CENTERLINE 2100 MCC lineup (for example, both front

and back MCCs in ‘back-to-back applications), must be mounted on

an adequate seismic foundation and installed per the seismic

anchoring requirements as shown in the following illustrations.

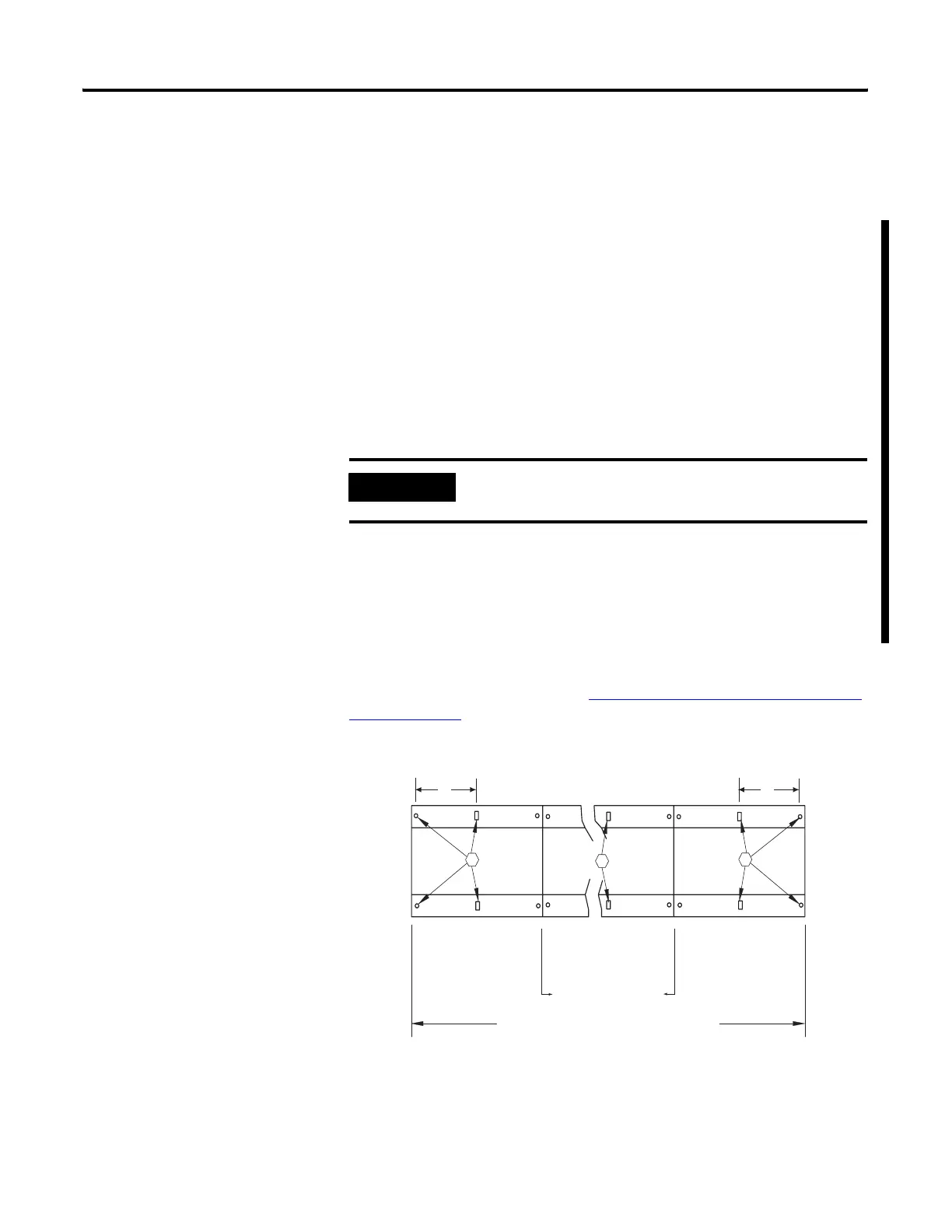

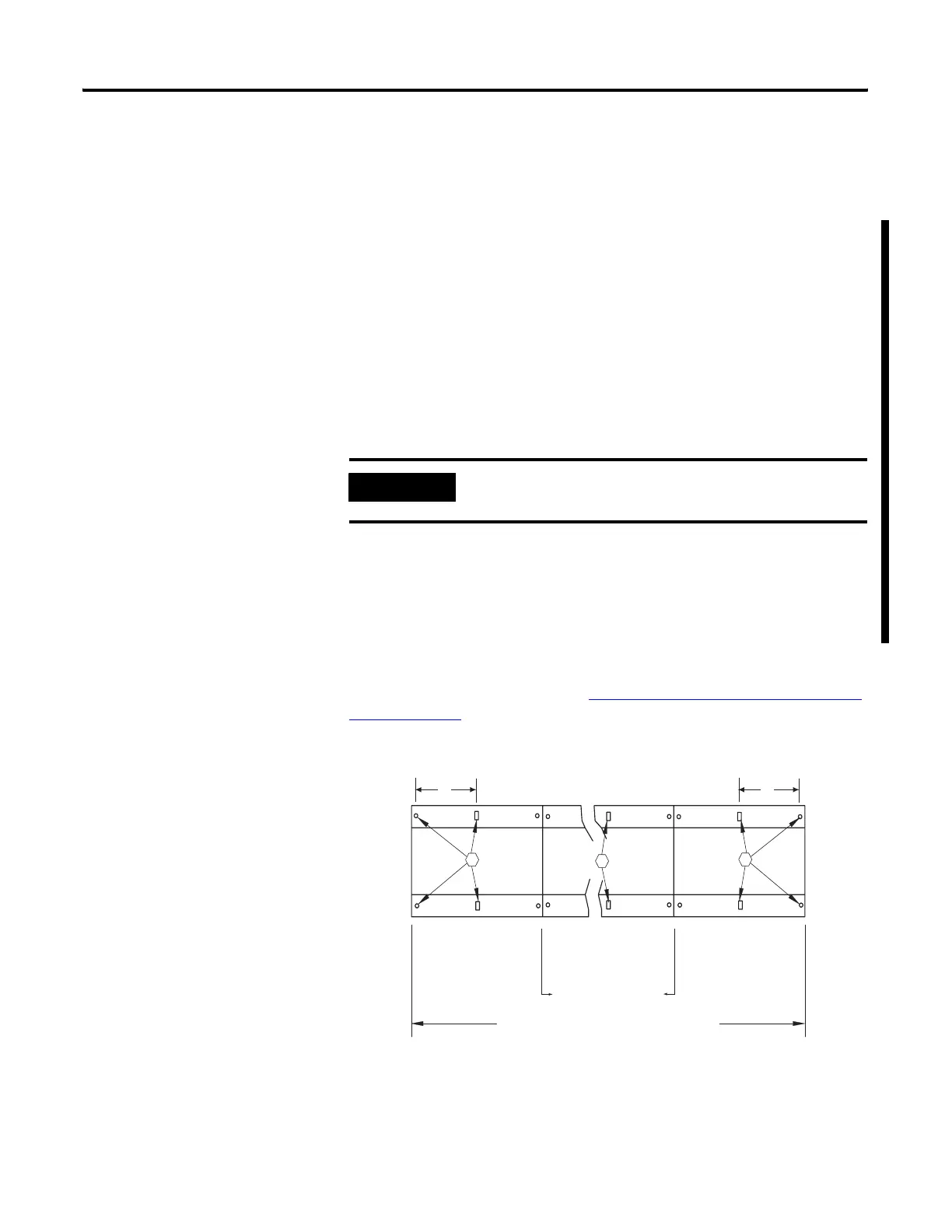

In seismic application dimensions ‘E’ applies to the first and last

sections of the MCC lineup. See Mounting Dimensions for 15 in. and

20 in. Sections for dimensions.

Seismic Bolt Down Requirements

IMPORTANT

Variable frequency drive units using ‘rollout’ drive

configurations are not seismically tested.

EERear

FrontFirst Section Last Section

Second Section and

Additional Sections

MCC Lineup

1

The hardware required is 1/2 in.-13 Grade 5 or HSL-3 M12 or better bolts embedded in the foundation.

1

1

1

Loading...

Loading...