4

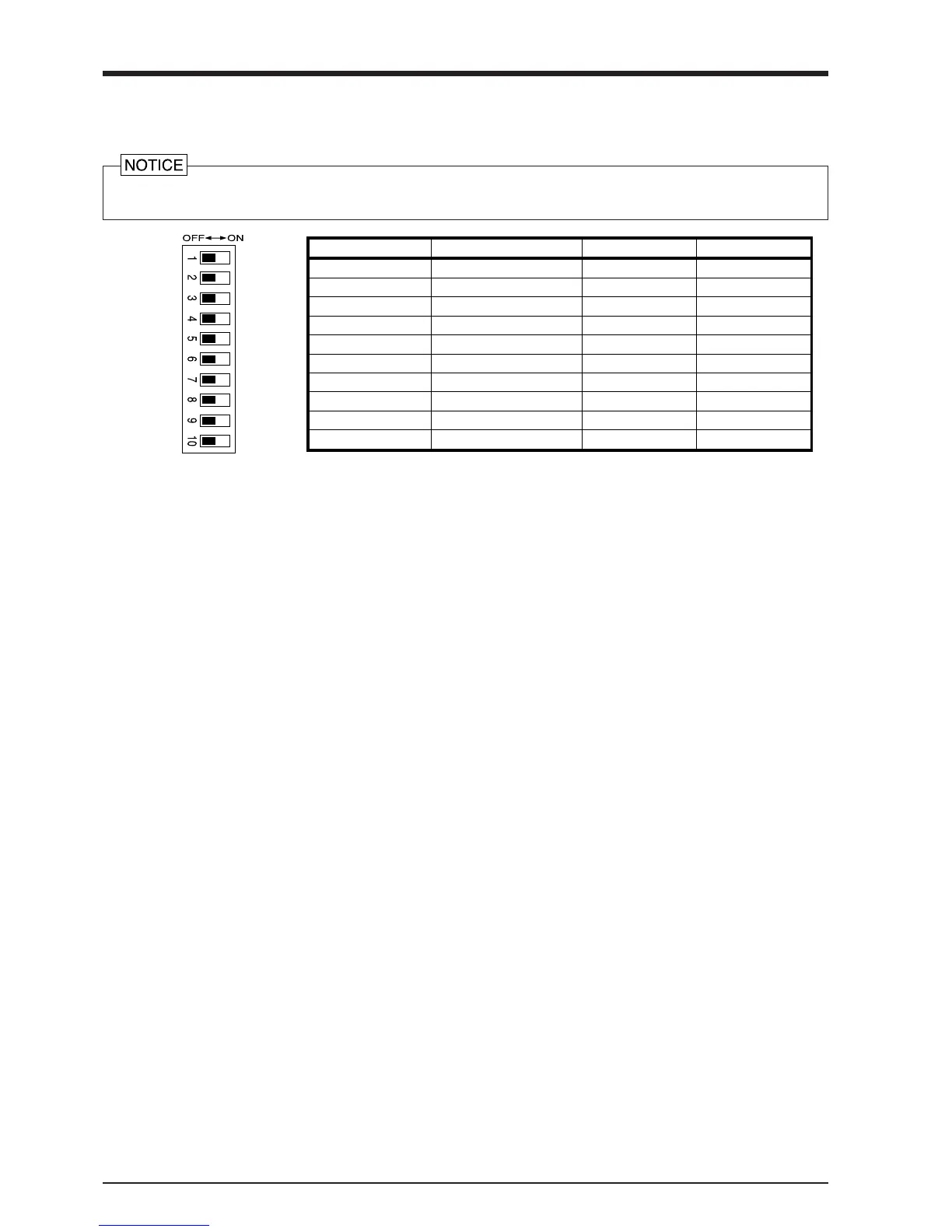

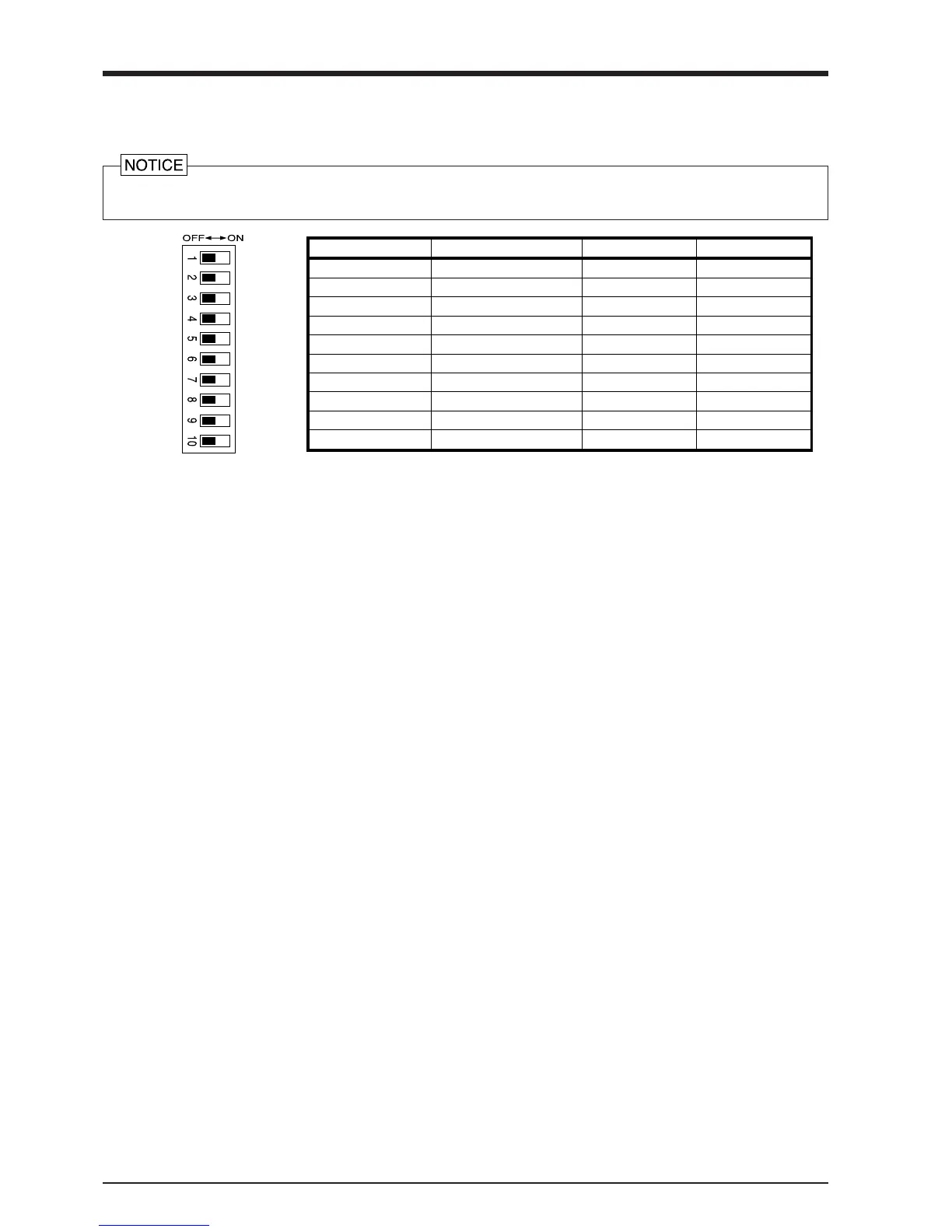

3-2 DIP Switch Settings

DIP switches settings must be made only when the power is turned off.

3 Basic Operation

- All DIP switches are set to OFF when shipped from the factory.

- When SW-2 is set to OFF, SW-3 may be set to either ON or OFF.

- When SW-8 has been set to ON (heavy), cutting speed is limited to the range of 10 to 100 mm/sec. At this time, operation never

exceeds 100 mm/sec., even is an instruction for a speed greater than 100 mm/sec. is received from the computer.

SW-1—6 : Sets the communication parameters for a serial connection. When the PNC-960/910 is connected to the computer

through the serial port, be sure that the communication parameters for SW-1 to SW-6 are set correctly, matching the

computer port settings.

SW-7 : Sets the amount of offset for the cutter blade. Set to OFF when using a tool with a blade offset of 0.25 mm, or to

ON when using a tool with a blade offset of 0.175 mm.

SW-7, which controls the blade offset, should normally be set to OFF (0.25 mm).

SW-8 : Sets the weight of the material. If the material is not cut even when the blade force has been increased, set this

switch to ON (heavy). When set to ON, the upper limit for cutting speed is set to 100 mm/sec., and the force used

to move the material and the blade increases. This switch should normally be set to OFF (light).

SW-9 : Sets the size of the material. Set this to ON when using a piece material (piece), and set it to OFF (roll) when using a

rolled material.

SW-10 : Smoothing is a function for cutting smooth circles and arcs. Smoothing is enabled when this switch is set to OFF

(enabled).

DIP switch Function OFF ON

SW-1 Baud rate 9600 4800

SW-2 Parity check Disable Enable

SW-3 Parity check ODD EVEN

SW-4 Data bits 8-bits 7-bits

SW-5 Stop bits 1-bit 2-bits

SW-6 Handshake Hardwire XON/OFF

SW-7 Blade offset 0.25 0.175

SW-8 Long output mode Light Heavy

SW-9 * Material size Roll Piece

SW-10 Smoothing ON OFF

* On the PNC-910, SW-9 is not used.

This switch should always be set to "OFF."

Loading...

Loading...