Instruc

tion

Com

patib

ility

Instruc

tion

Com

patib

ility

Instruc

tion

Com

patib

ility

Instruc

tion

Com

patib

ility

!NR !PG !ST !FS

• Device Control Instruction

Handshake Instructions

Instruc

tion

Com

patib

ility

Instruc

tion

Com

patib

ility

Instruc

tion

Com

patib

ility

Instruc

tion

Com

patib

ility

Instruc

tion

Com

patib

ility

Instruc

tion

Com

patib

ility

Instruc

tion

Com

patib

ility

Instruc

tion

Com

patib

ility

Instruc

tion

Com

patib

ility

ESC.B ESC.M ESC.N ESC.H ESC.I ESC.@ ESC.O ESC.E ESC.L

About Instructions

ESC.J ESC.K ESC.R

The material slips away from the pinch rollers during the cutting process

Are the sheet loading levers lowered? If the sheet loading levers are raised, then make sure the left and right pinch rollers are within

the edged of the material and lower the sheet loading levers. (Refer to "3-4 Loading/Removing

the Material Loading the Material".)

Make sure the material is parallel with the grit

roller.

If the front edge of the material you are working with is at an angle, cut off the odd-shaped

part to make it straight, then align it so that it is parallel with the grit roller.

If the material is to be advanced over a long distance, moving the movable pinch roller inward slightly can help prevent the material from

becoming dislodged. Also, after loading the material, it is recommended that you carry out an alignment test by using the key to advance the

material by the amount that will be used for cutting, and make sure that the material travels correctly through the machine.

If a roll material is used, carry out cutting after first pulling out the amount of material that is to be used. The material may easily slip if cutting is

performed while pulling a material that is still rolled up into the PNC-960/910.

Make sure that the left and right edges of the material do not touch the inner surfaces of the PNC-960/910 during cutting. Such contact may not

only damage the material, but could also make normal material advancing impossible and cause the material to slip.

The PEN MODE LED and POWER/ERROR LED blink simultaneously

This flashes if the location of the pinch rollers is not correct, if DIP switch SW-9 on the PNC-960 is set to ON (piece material) and material

with a vertical length of 100 mm (3-15/16") or less has been loaded, or if SW-9 is set to ON and there is no material over the front and rear paper

sensors. You can cancel the error by pressing the SETUP key. Refer to "3-4 Loading/Removing the Material Loading the Material" to load the

material correctly.

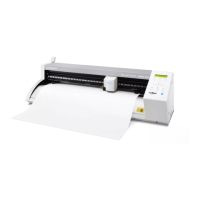

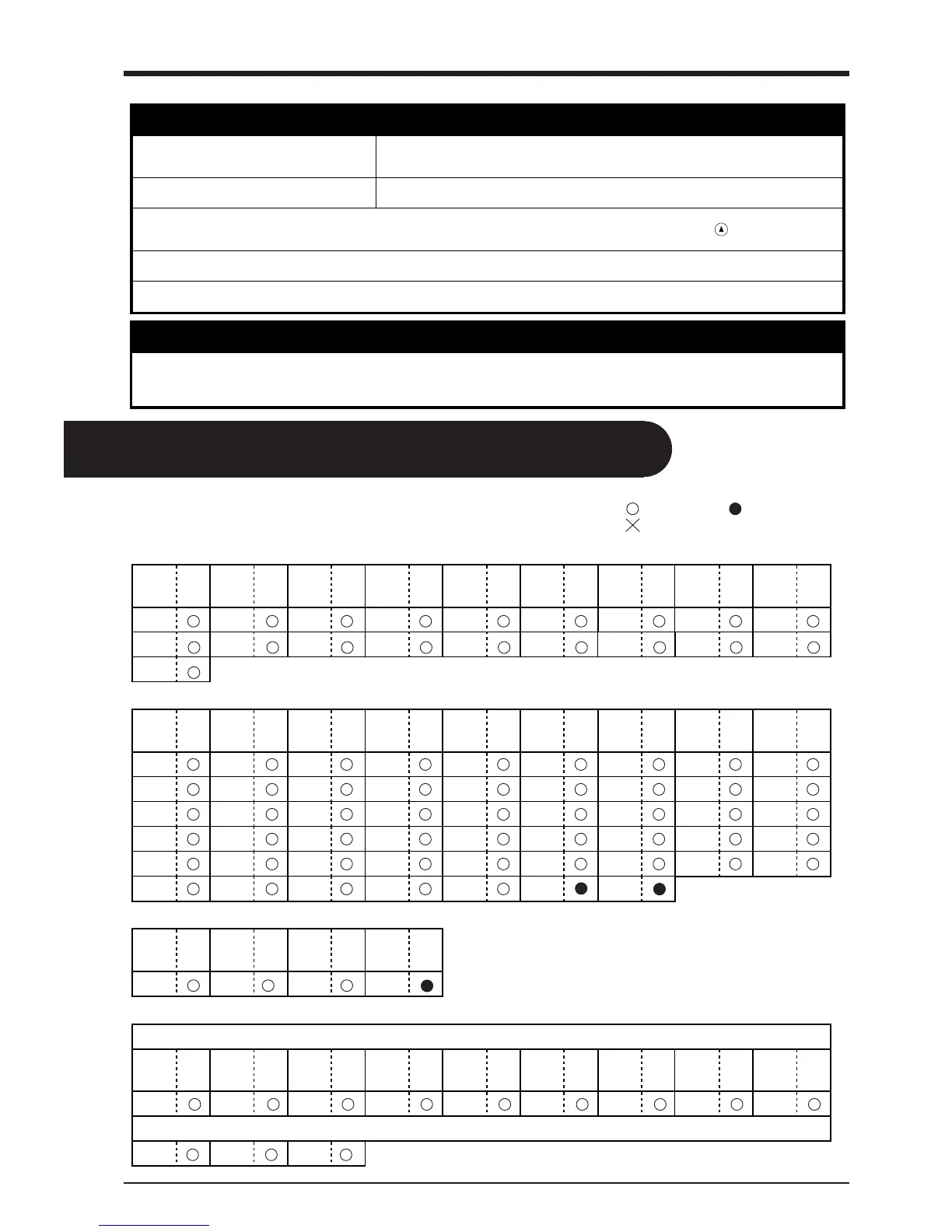

7 Instruction Support Chart

A "CAMM-GL III Programmer's Manual" is available for separate purchase for

those wishing to create their own programs for this machine. For further informa-

tion, please contact the nearest Roland DG Corp. dealer or distributor.

The list uses marks, each of which means:

:Compatible. :Ignored.

:Incompatible.

6 What to do if... / 7 Instruction Support Chart

Loading...

Loading...