2

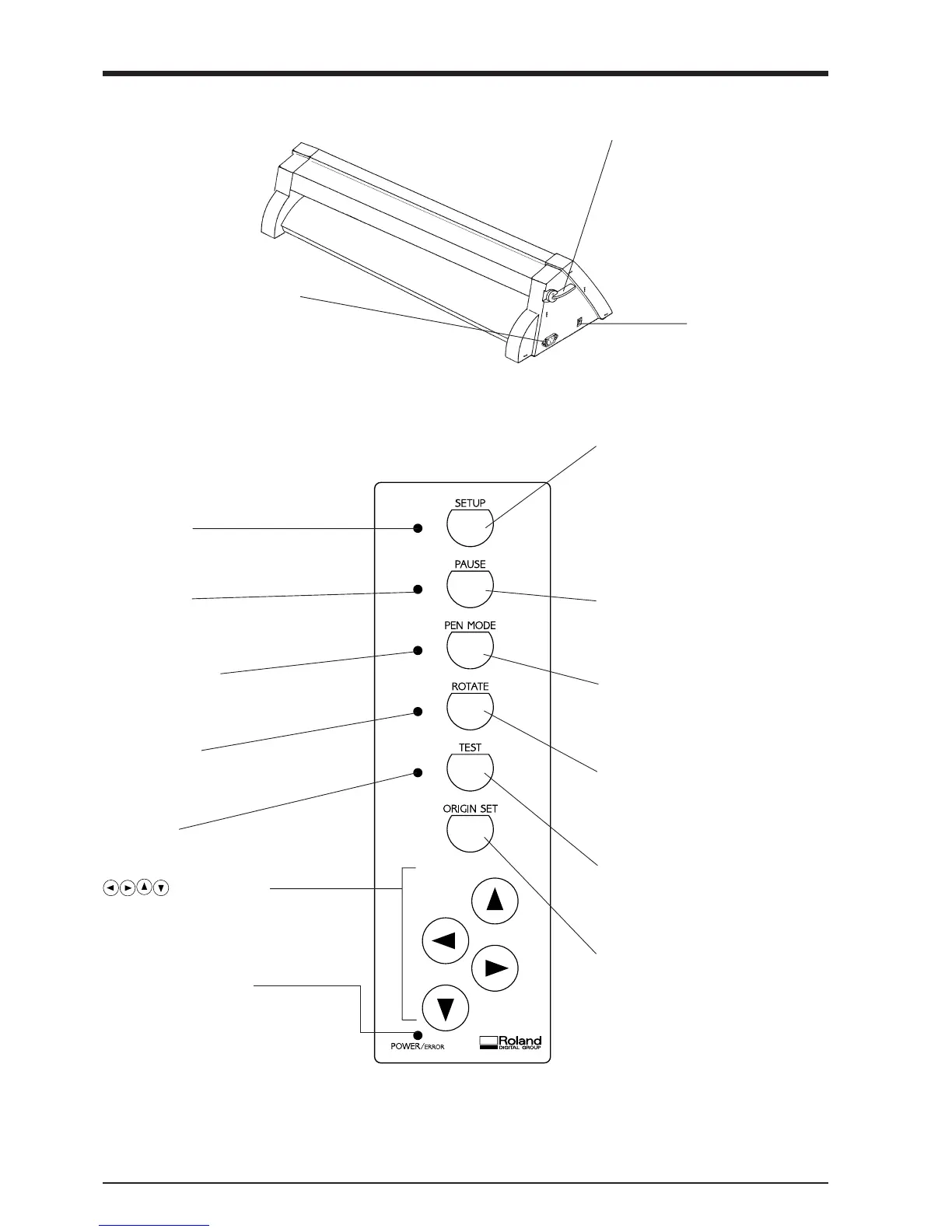

2-2 Rear View

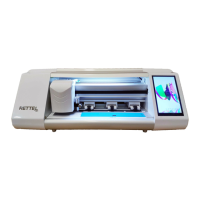

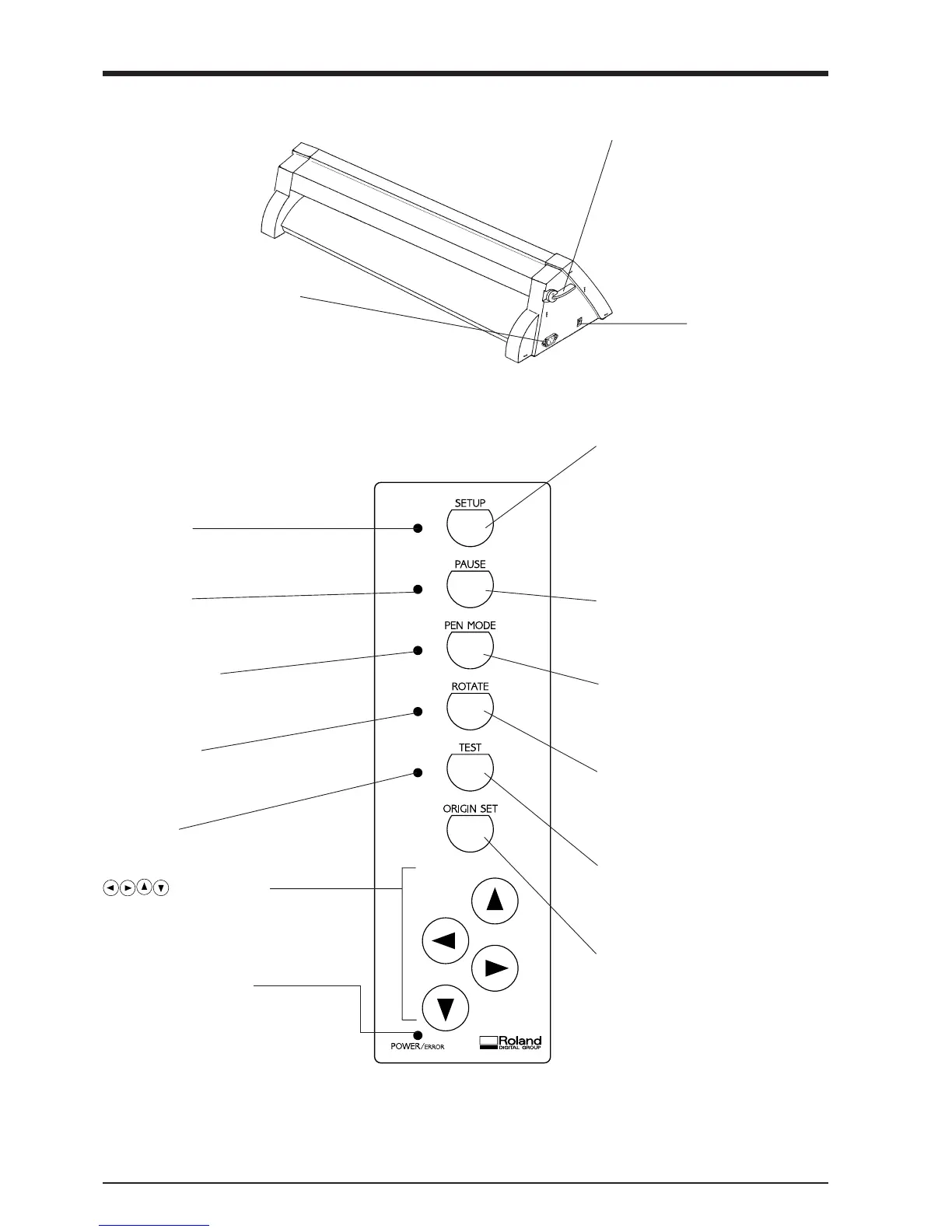

2-3 Operation Panel

Power Connector (AC IN)

This connector accepts standard AC

power cord.

Sheet Loading Lever

This moves the pinch rollers up and

down to load and release the material.

Power Switch

ON when switched to [I].

OFF when switched to [O].

* The TEST key and the position keys function only

when the SETUP LED is lighted, and the ROTATE key

functions only when the SETUP LED is not lit.

2 Part Names and Functions

SETUP Key

Press this to detect the width of the loaded

material and enable the unit for cutting.

Pressing this while operation is paused deletes

the data sent from the computer.

PAUSE Key

When pressed once, this temporarily halts

cutting in progress. Pressing this key again

releases the paused state.

PEN MODE Key

Press this to perform plotting with a pen on

paper. (Be sure to load a pen in the tool

carriage.)

ROTATE Key

Pressing this key sets the origin point at the

bottom right of the material and rotates the

direction of cutting by 90°.

TEST Key

This performs a cutting test to check whether

blade force is correct.

ORIGIN SET Key

This sets the origin point for cutting to the

current tool position.

(Position Keys)

These are used to move the material or the tool

carriage.

SETUP LED

This lights up when the SETUP key is pressed.

Cutting can be performed when this is lit.

PAUSE LED

This lights up when the PAUSE key is pressed to

pause the PNC-960/910.

PEN MODE LED

This lights up when the PEN MODE key is

pressed.

ROTATE LED

This lights up when the ROTATE key has been

pressed.

TEST LED

This lights up when the TEST key is pressed.

POWER/ERROR LED

This lights up when the power is switched on,

and flashes when an error is generated.

The PEN MODE LED and POWER/ERROR LED blink simultaneously.

This flashes if the location of the pinch rollers is not correct, if DIP switch SW-9 on the PNC-960 is set to ON (piece material) and material

with a vertical length of 100 mm (3-15/16") or less has been loaded, or if SW-9 is set to ON and there is no material over the front and rear paper sensors.

For more details, see "3-4 Loading/Removing the Material".

Loading...

Loading...