1

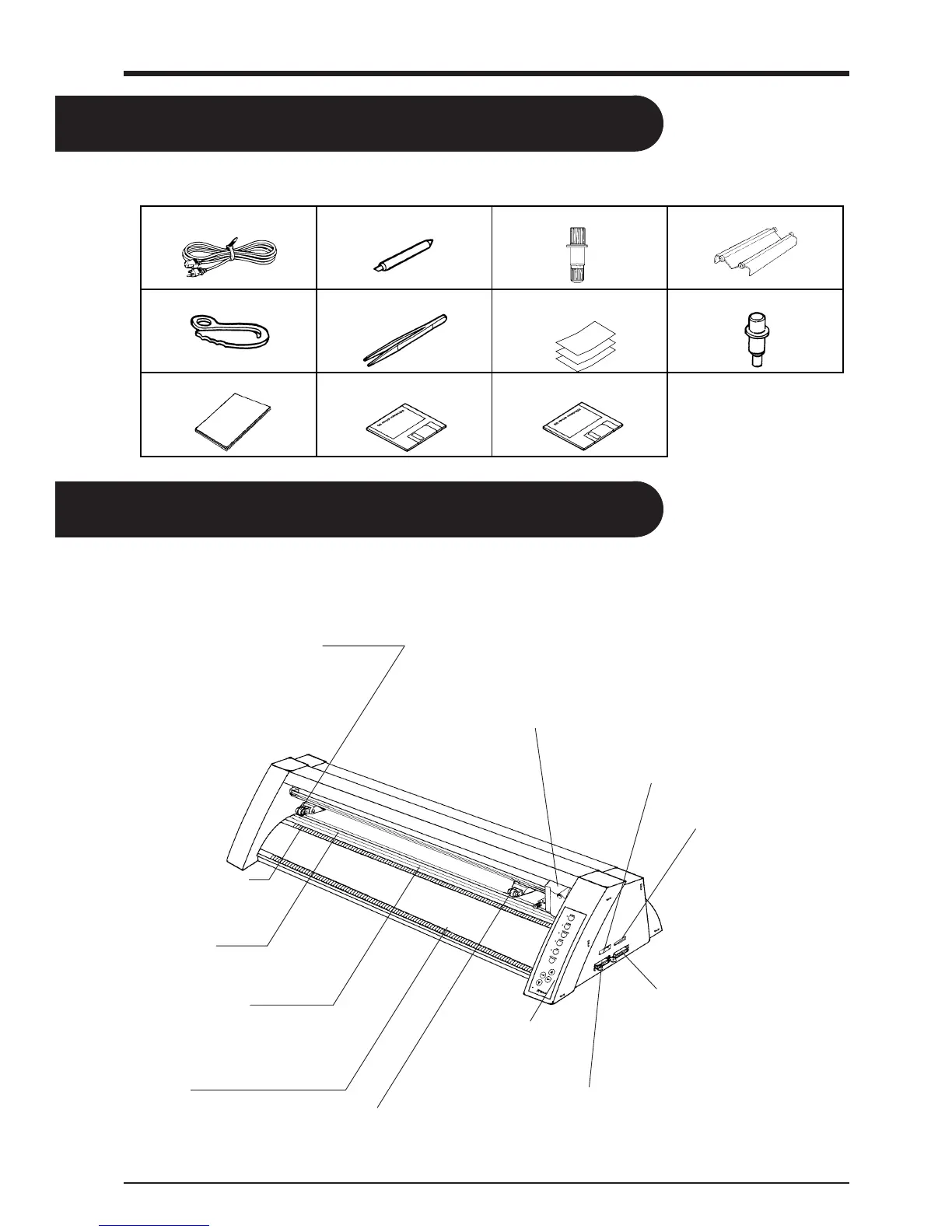

Power Cord:1 Blade (ZEC-U1005):1 Blade Holder (XD-CH3):1 Roller Base:1

Cutter Tool:1 Tweezers:1 Test-use High-quality Paper/Material for

Test Cuts/Test-use Application Tape:

1 piece each

Test-use Water-based Fiber-tipped Pen:1

User's Manual:1 CAMM-1 DRIVER for windows 95:1 CAMM-1 DRIVER for windows 3.1:1

1 Checking Supplied Items/2 Part Names and Functions

Check the following to make sure that you received all the items that were shipped along with the unit.

*PNC-960 only

*PNC-960 only

*PNC-960 only

1 Checking Supplied Items

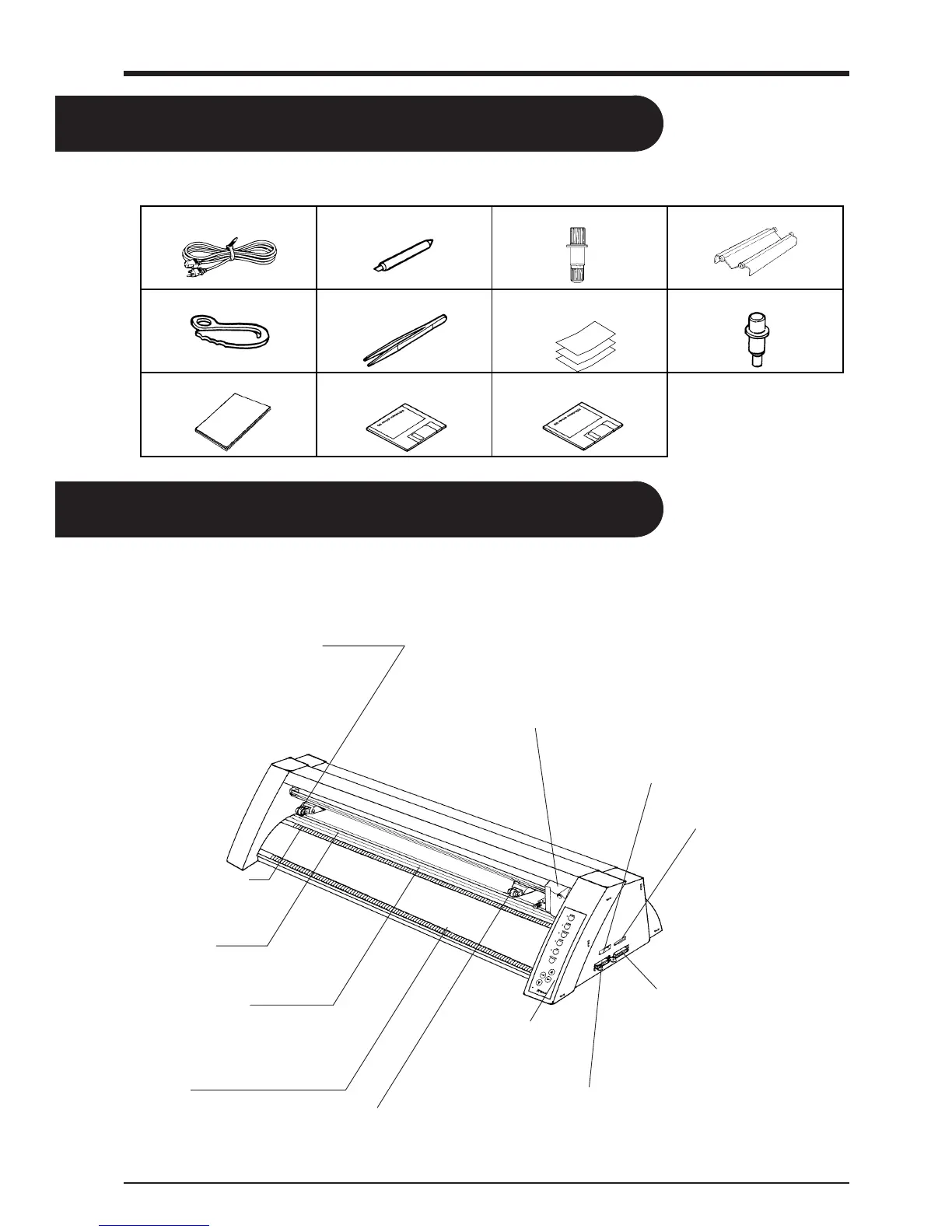

2 Part Names and Functions

2-1 Front View

* In this manual, the sections that explain both the PNC-960 and

the PNC-910 shown only illustrations of the PNC-960.

Movable Pinch Roller (Left)

Press material against the grit roller.

This is aligned with the left edge of the loaded

material and set in place.

Tool Carriage

The tool (blade or plotting pen) is

installed here. The tool carriage performs

the cutting by moving the tool left/right

or up/down.

Pen Force Control Slider

Sets the blade force to be used with the tool.

DIP Switches

Used to make various settings.

Serial (RS-232C) Input Connector

In a serial configuration, this connector is

where you need to connect the serial cable that

is used to communicate with your computer.

Operation Panel

Parallel (Centronics) Input Connector

In a parallel configuration, this connector is where

you need to connect the parallel cable in order to

communicate with your computer.

Movable Pinch Roller (Right)

Press material against the grit roller.

This is aligned with the right edge of the

loaded material and set in place.

Platen

The material is moved over the

platen.

Cutter Protector

The tool carriage moves

above the blade

protector, and cutting is

carried out here.

Grit Roller

This moves the material

to the front and rear.

Guide Line Mark

Material is loaded in

alignment with the guide-

line marks.

Loading...

Loading...