7 x Service and maintenance

BA ROTEX HPSU compact 4 - 09/2013

39

7 Service and maintenance

7.1 General service and maintenance

Regular inspection and maintenance of the HPSU compact

reduces energy consumption and ensures a long life and smooth

operation.

Have the inspection and maintenance carried out by

authorised and trained HVAC engineers once a year,

ideally before the heating period. This can prevent

faults during the heating period.

ROTEX recommends an inspection and maintenance

con

tract to ensure regular inspection and maintenance.

Legal requirements

According to the F-gases directive (EC) No. 842/2006 pos. 3,

operators (or owners) must regularly service their stationary

cooling systems on a regular basis, check for leaks and remedy

any leaks found as quickly as possible.

All maintenance and repair work on the refrigeration circuit must

be documented in the operating manual. This obligation results

from the directive published on June 14th 2006 in the EU official

gazette concerning greenhouse gases.

Operators of ROTEX heat pump systems are subject to the

following obligations:

If the total filling quantity of the system with refrigerant

is less than 3 kg, there is no European legal require-

ment for testing intervals. ROTEX however, would

recommend entering into a maintenance contract and

record

ing the work carried out in the operating manual

in order to preserve guarantee claims.

● With a total filling quantity of the system with refrigerant of

3 kg – 30 kg or from 6 kg upwards in hermetic systems:

Checks by certified personnel at intervals no longer than

12 months.

● Compul

sory documentation (maintenance and leak test) in

the operating manual, stating type and amount of filled-in

or recovered refrigerant and the applied test method (in

accordan

ce with EC No. 1516/2007). Operator must keep

documentation for at least five years after compiling it and

show it to the responsible authority upon request.

● Respo

nsibility of the operator of systems for recovering

F-gases by certified personnel.

Certified people are those who have proof of expertise

for the European Community for work on stationary

refrigeration systems (heat pumps) and air conditioning

systems, according to the F-Gases Directive (EC)

No. 842/2006.

–Up to 3 kg coolant fill quantity: Expe

rt certificate

category 2

–3 kg coolant fill quantity or over: Exp

ert certifi-

cate category 1

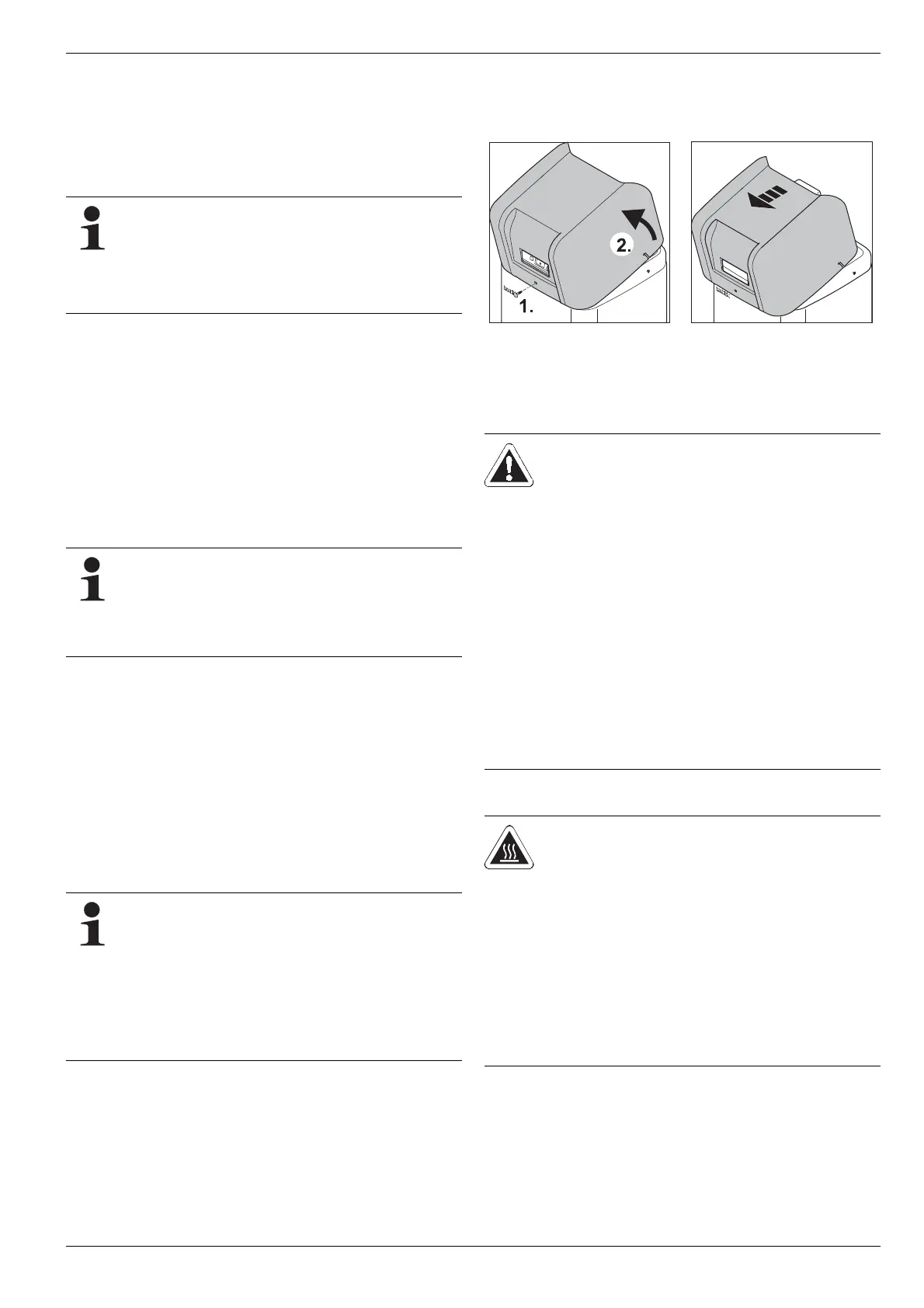

7.2 Removing the protective cover

Fig. 7-1 Unscrew the bolt and

unlock the rear protec

-

tive cover.

Fig. 7-2 Remove the protective

cover

upwards and

towards the front.

7.3 Activities to be performed annually

WARNING!

Improperly carried out work on

the HPSU compact and

its components that have been connected as an option

can endanger human life and health and adversely

affect the operation of the these components.

● Wo

rk on the HPSU compact (such as maintenance

or servicing) is only to be carried out by persons

who are authorised and who have successfully

completed qualifying technical or vocational

training and who have taken part in advanced

training sessions recognised by the appropriate

responsible authorities. These include in particular

certified heating engineers, qualified electri-

cians and HVAC specialists,

who because of

their professional training and expert

knowledge, have experience in the professional

installation and maintenance of heating, cooling

and air conditioning systems and heat pumps.

WARNING!

Under the cover o

f the HPSU compact temperatures

of up to 90 °C can

arise during operation. During

operation, hot

water temperatures > 60 °C arise.

– Touching components during or after operation

leads to a risk of burns.

– Water discharged during maintenance and servic-

ing work can cause sca

lding on contact with the

skin.

● Before carrying

out servicing and maintenance

work, allow the HPSU compact to cool down suffi-

ciently.

● We

ar protective gloves.

Loading...

Loading...