7 SERVICE

12

NOTE: Inside surface of bushings has a special coating.

DO NOT ream or sand inside surface.

Guide Repair:

• Remove seal and bushings.

• Press in new bushings and check passage with slide.

• Install seal flush with guide surface.

NOTE: Inside surface of bushings has a special coating.

DO NOT ream or sand inside surface.

Apply H.D. 85–140W oil to lip of seal, bushings and

black surface of slide assembly prior to installing

slide into guide.

12. Reassemble slide, slide guide and spring. Compress

spring and install spring retainer, roller, screw and

nut. Torque nut to 26 ft. lbs. (35 N·m) and apply Loc-

tite #290 or equivalent where threads make contact

with nut.

13. Compress spring and replace 1/2”(13mm) wood

block previously removed.

14. Apply 3M Sealer #EC847 or equivalent to slide guide

and screws before installing slide guide to cam case.

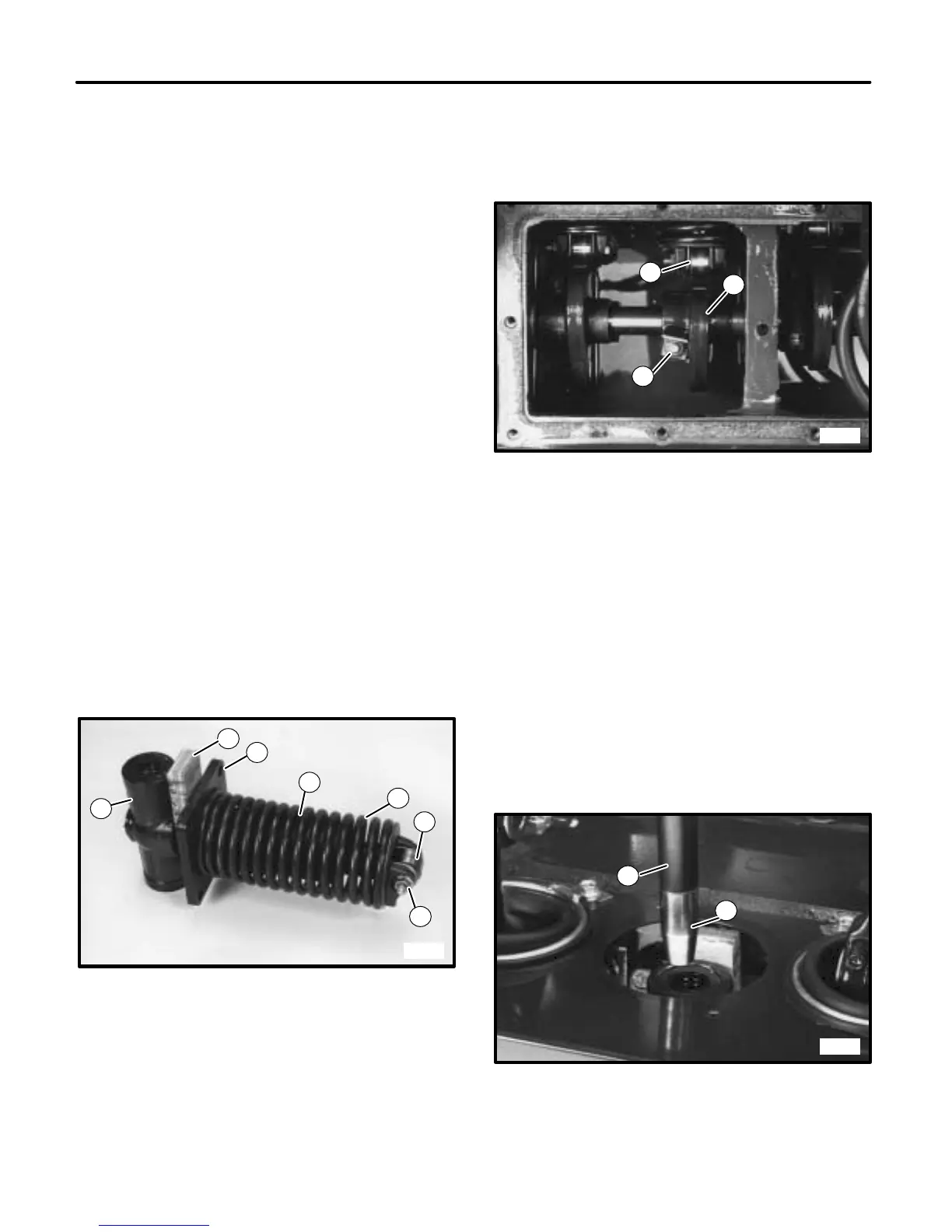

NOTE: When installing slide guides, make sure the slot

in guide is on top. (See FIGURE 11.)

3

4

3786

2

1

5

6

7

FIGURE 11

1. Slot

2. Slide Guide

3. Slide

4. Wood Block

5. Spring

6. Roller

7. Screw and Nut

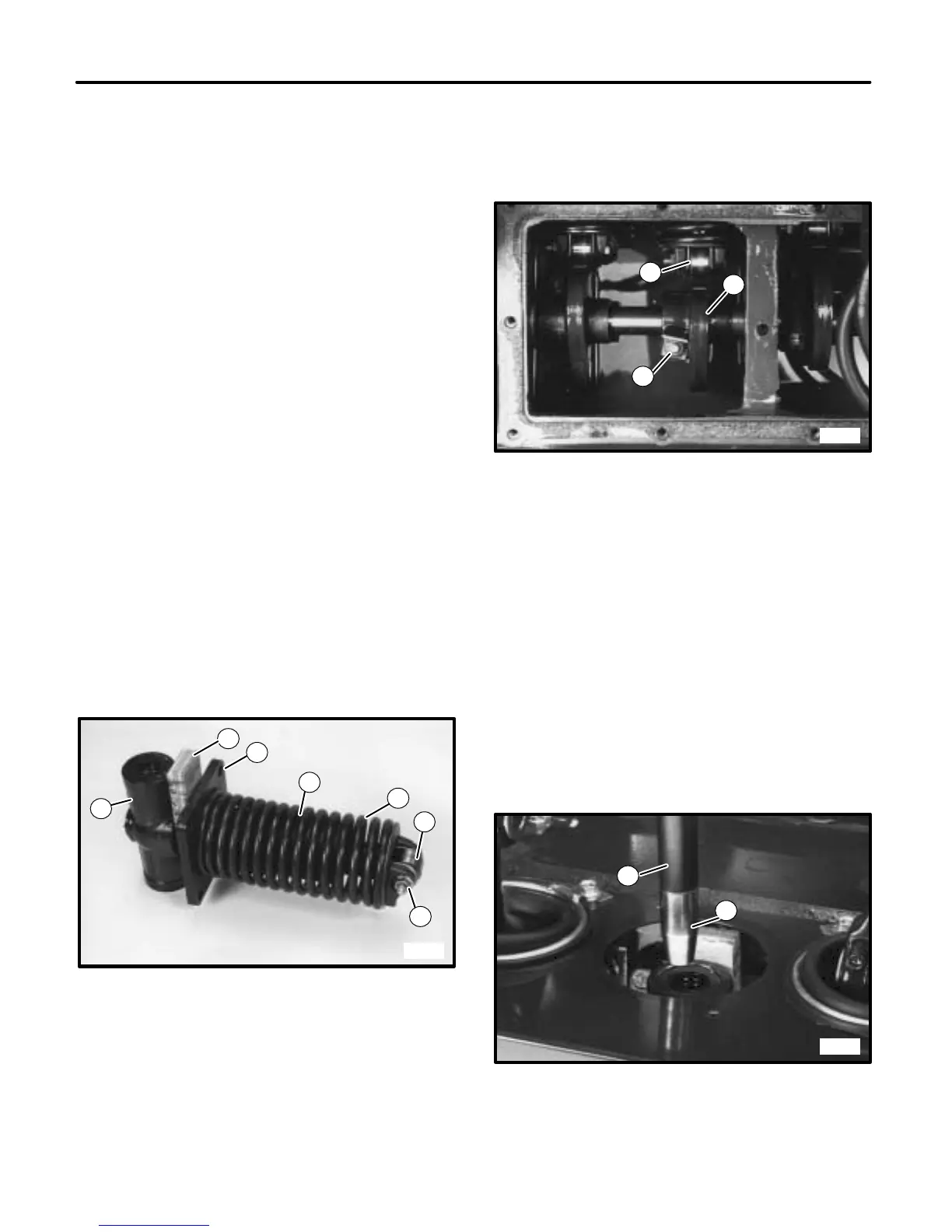

15. Check to make sure cam and roller of slide are

aligned properly. To align, loosen cam screw and

slide cam on shaft until it is centered on roller.

Tighten cam screw. (See FIGURE 12.)

3787

2

1

3

FIGURE 12

1. Slide Roller

2. Cam

3. Cam Screw

16. Rotate cam so that slide is pushed out and remove

wood block.

17. Reinstall cam case cover. Replace gasket if broken

or damaged.

18. Refill cam case with oil (see lubrication section for

recommended type). Check level with unit in raised

position.

NOTE: To reinstall push rods to slides, a seal protector

tool (P.N. 517693) is required to prevent damage to

triple lip seals. (See FIGURE 13.)

3789

2

1

FIGURE 13

1. Push Rod

2. Seal Protector Tool

Loading...

Loading...