SERVICE 7

27

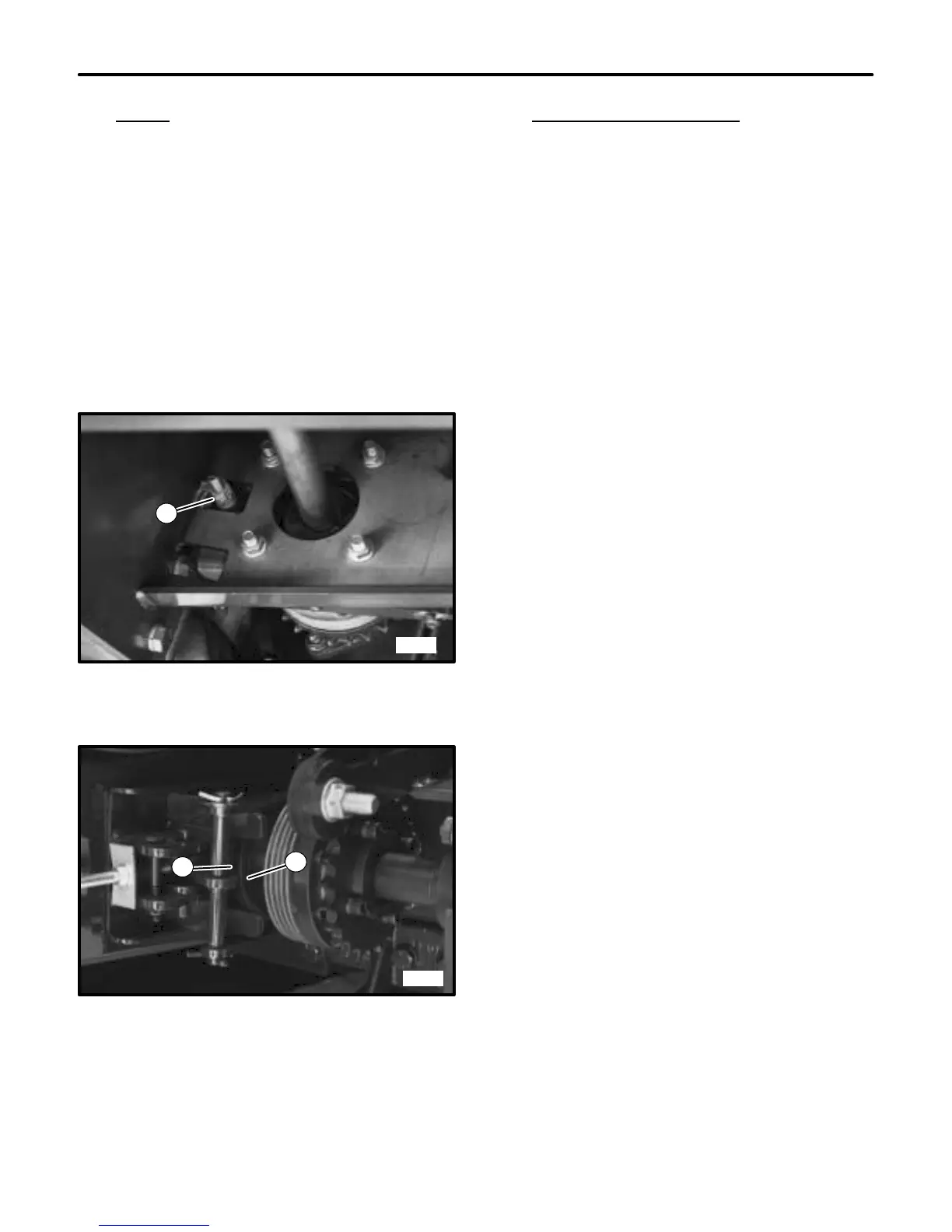

7.16 BRAKE/CLUTCH ADJUSTMENT

The unit’s brake is automatically applied when the mas-

ter clutch is disengaged while in either the “Transport” or

“Aerate” mode. Anytime the clutch is removed from the

unit and reinstalled, the brake should be adjusted.

1. With engine stopped, place Shift Control lever to

“Transport” or “Aerate” and engage master clutch.

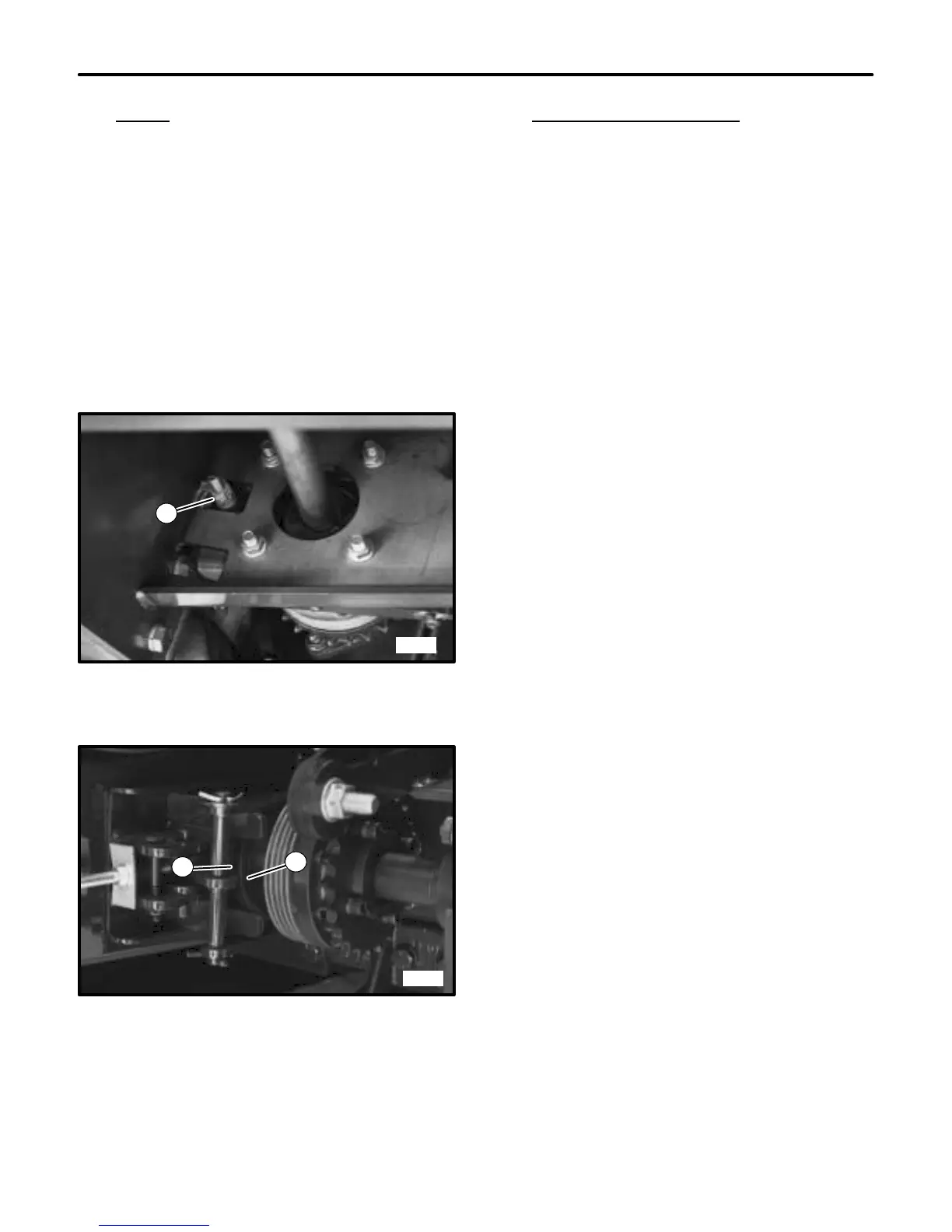

2. Adjust Brake/Clutch Adjustment nut, located

beneath engine frame (See FIGURE 47), to obtain a

clearance of .015” to .025” between the friction plate

and pressure plate. (See FIGURE 48.)

3809

1

FIGURE 47

1. Brake/Clutch Adjustment Nut

3810

1

2

FIGURE 48

1. Friction Plate

2. Pressure Plate

7.17 LUBRICATION

Refer to FIGURE 49, FIGURE 50 and FIGURE 51 for fit-

ting locations.

Daily:

Crankshaft Bearings;

Lubricate fittings on crank supports with lithium base

EP Moly Lube.

Drive Shaft and Idler Sprockets;

Lubricate fittings in shaft with lithium base EP Moly

Lube.

Roller Chains;

Apply No. 30 oil or penetrating chain lubricant.

Dog Clutches;

Lubricate with lithium base EP Moly Lube.

Pillow Blocks;

Lubricate fittings with lithium base EP Moly Lube.

Connector Rod Bearings;

Lubricate Fitting in caps with lithium base EP Moly

Lube.

Hydraulic Reservoir Tank;

Check in Raised position.Fill as required with API

Grade CC or SF-FG SAE 20–20W

Bi–annually:

Camcase;

Models 9110 and earlier:

Drain and Refill with Multigrade 85–140 oil.

Models after 9110 or with new slides:

Drain and Refill with 30 weight oil.

Yearly:

Shift Control Lever;

Lubricate pivot points with engine oil.

Tine Control Lever;

Lubricate pivot points with engine oil.

Wheel Bearings (front wheels);

Lubricate fitting in hub with lithium base EP Moly

Lube.

Loading...

Loading...