SERVICE 7

13

19. Reinstall push rod and reattach push rods to con-

necting rods with wrist pin and bearings.

20. Replace all shields before operating unit.

7.7 HYDRAULIC HOSE REPLACEMENT

WARNING

DO NOT attempt to replace hydraulic hoses

while unit is in raised position. Hoses are under

extreme pressure. Releasing pressure improp-

erly could cause unit to drop rapidly.

Hydraulic fluid escaping under pressure can

have sufficient force to penetrate skin, causing

serious injury.

If a leak is suspected, use a piece of cardboard

or wood, not your hand, to check for leaks.

If injured by escaping fluid, see a doctor at

once. Serious infection or reaction can develop

if proper medical treatment is not administered

immediately.

Do not use a unit with a leaking hydraulic sys-

tem. See your authorized CUSHMAN dealer for

necessary repairs.

!

1. With engine stopped, move the Tines Control lever

to “Raise” for approximately 10 seconds. Then to

“Lower” for approximately 10 seconds. This releases

all pressure from the hydraulic hoses and cylinders.

2. Remove damaged hoses and install new ones using

pipe sealant on threads of each fitting.

3. Start engine and check for leaks while raising and

lowering the tines several times.

4. Check hydraulic fluid lever in reservoir, add if neces-

sary.

7.8 DOG CLUTCH ADJUSTMENT

(Refer to diagram, page 15.)

1. Raise unit, stop engine and block chassis to prevent

dropping.

2. Remove shields.

3. Disconnect connecting link (item 1 in diagram) from

transport clutch bell crank by removing clevis pin (5).

Remove rod connector link (3). Loosen connector

link (2) by backing both locknuts away from the

swivel pin.

4. Make sure clutches slide easily on shaft and engage

fully. If not, clean and lubricate shaft and clutch.

5. Tighten any play that may exist at joints where levers

clamp onto fork shafts.

6. Set Shift Control lever to “Neutral”. Hold or block the

lever so that it is tight against the top of its detent

hole.

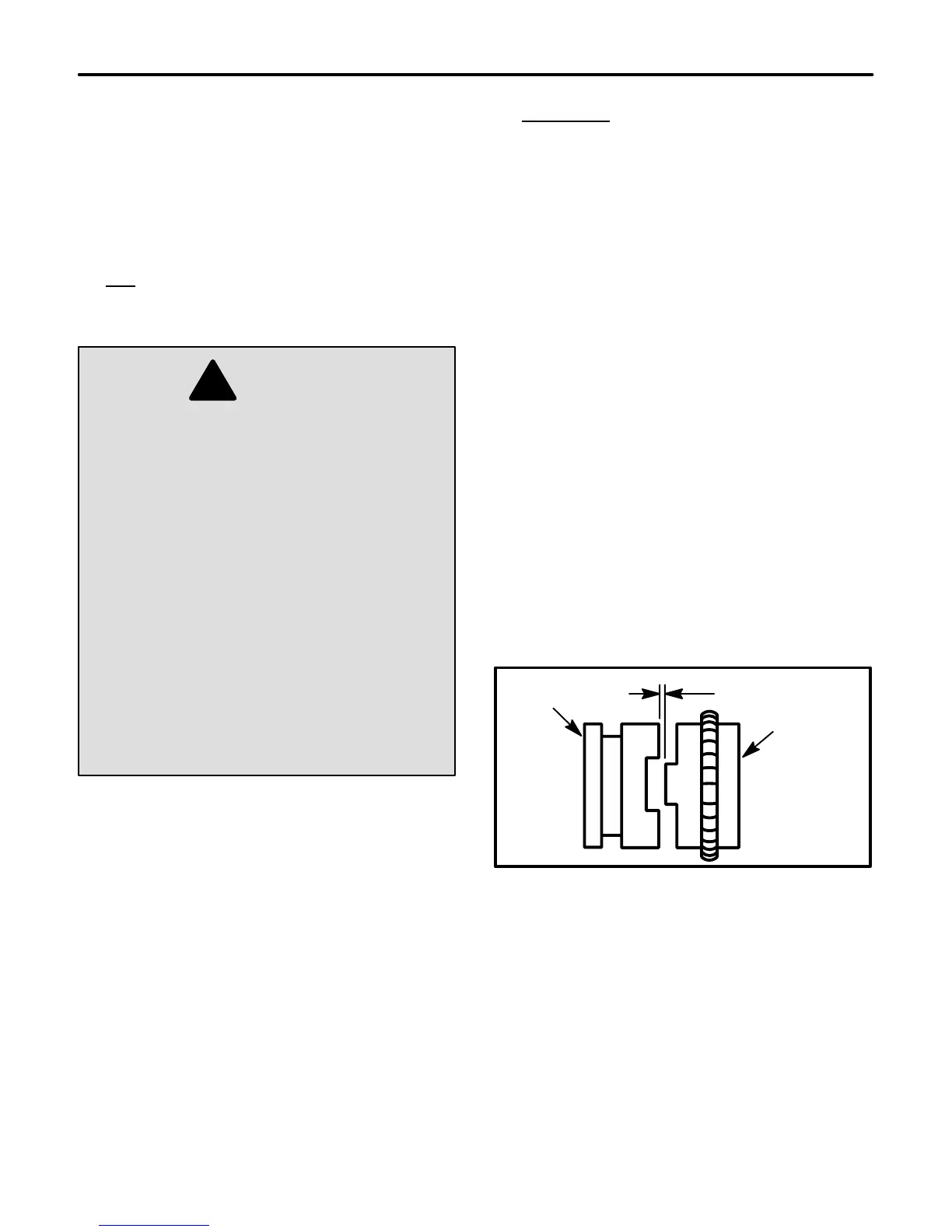

7. Move clutch lever (9) to attain a clearance of

.015”(.38mm) between the faces of the transport

clutch dogs. (See FIGURE 14.)

.015” (.38mm)

Sprocket

Dog Clutch

FIGURE 14

Transport Clutch Clearance (Neutral)

8. Tighten locknuts on connector link (2) against swivel

pin to maintain clearance.

9. Move shift control lever to “Aerate”.

10. Move lever (4) to fully engage aerate clutch with

.015”(.38mm) clearance. (See FIGURE 15.)

[Transport clutch should now be 1/16–3/32”

(1.5–2.5mm) from the edge of the drive shaft.]

Loading...

Loading...