5.1 Three-step controller with internal feedback (

Y

=

1

)

The three-step controller incorporating internal feedback is selected in the configuration level

with configuration switch

Y

=

1

.

In this configuration scheme, switching output

Y1

is then active when the difference between the

calculated

Y

PID

signal and the internal feedback is positive. Switching output

Y2

is always active

when this difference is negative.

With dead band

td

, a range (neutral zone) can be defined in which the switching signal is still

not to be active.

Dead band

td

applies in equal proportions for positive and negative output signals (50% each).

The hysteresis which can be commonly set for both switching points is set as a percentage using

parameter

tH

.

Example:

Y

PID

= 20 %;

YR

= 16 %;

Y

=

Y

PID

–

YR

= 20 % – 16 % =

4 %

.

In a situation where the set dead band

td

= 10 %,

Y1

is not active. Reason: 5 % dead band for

positive output signals is not exceeded. If differential gap

tH

is set with 1 %, then

Y1

is only active

when

Y

> 5 %.

Y1

is then disabled whenever

Y

< 4 %.

The internal feedback is to be adapted, in seconds, to the installed actuator using parameter

t1

(motor operating time). The internal feedback simulates the behaviour of the installed actuator.

By inserting an internal feedback, the discontinuous-action controller output takes on a beha-

viour resembling that of a continuous controller output (quasi-continuous controller output).

t1

= Operating time of the implemented actuator (in seconds)

td

= Dead band as a percentage

tH

= Hysteresis as a percentage

For the selection of three-step controller providing internal feedback (

Y

=

1

), configuration

blocks

Y1

and

Y2

are insignificant and cannot be altered.

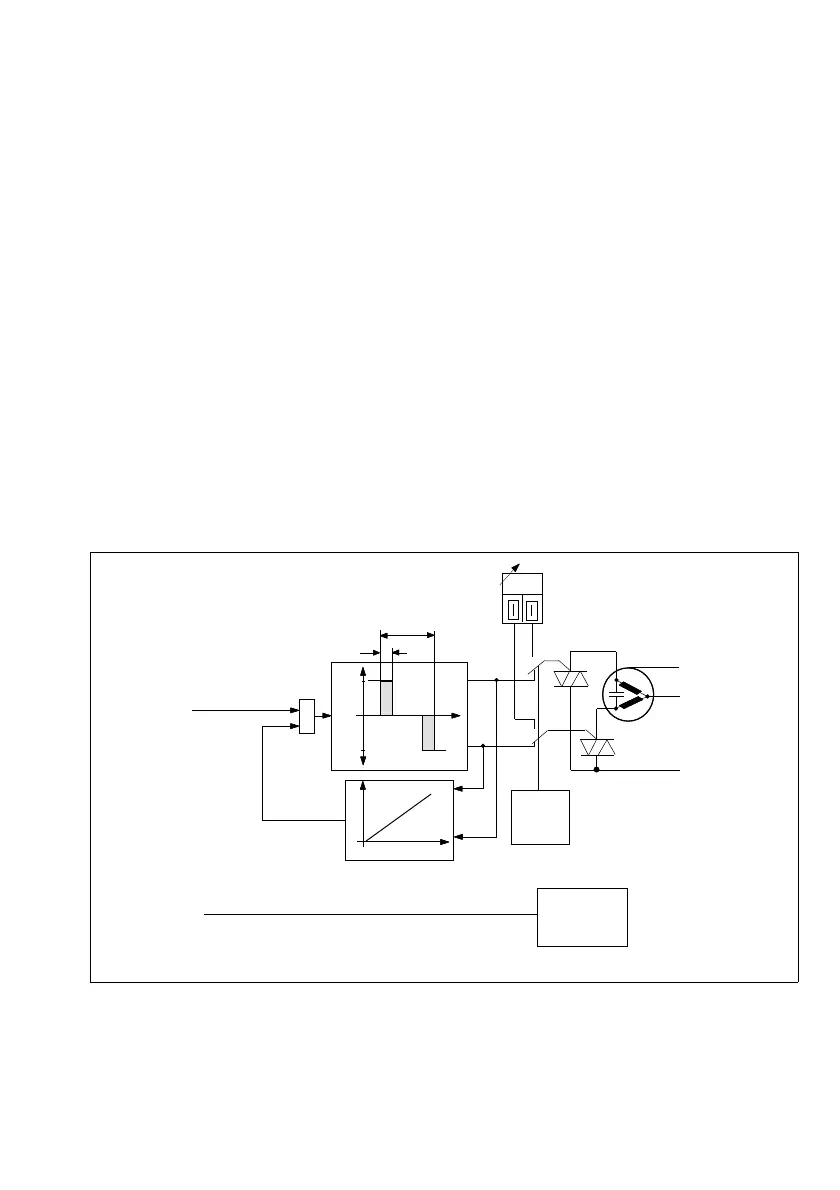

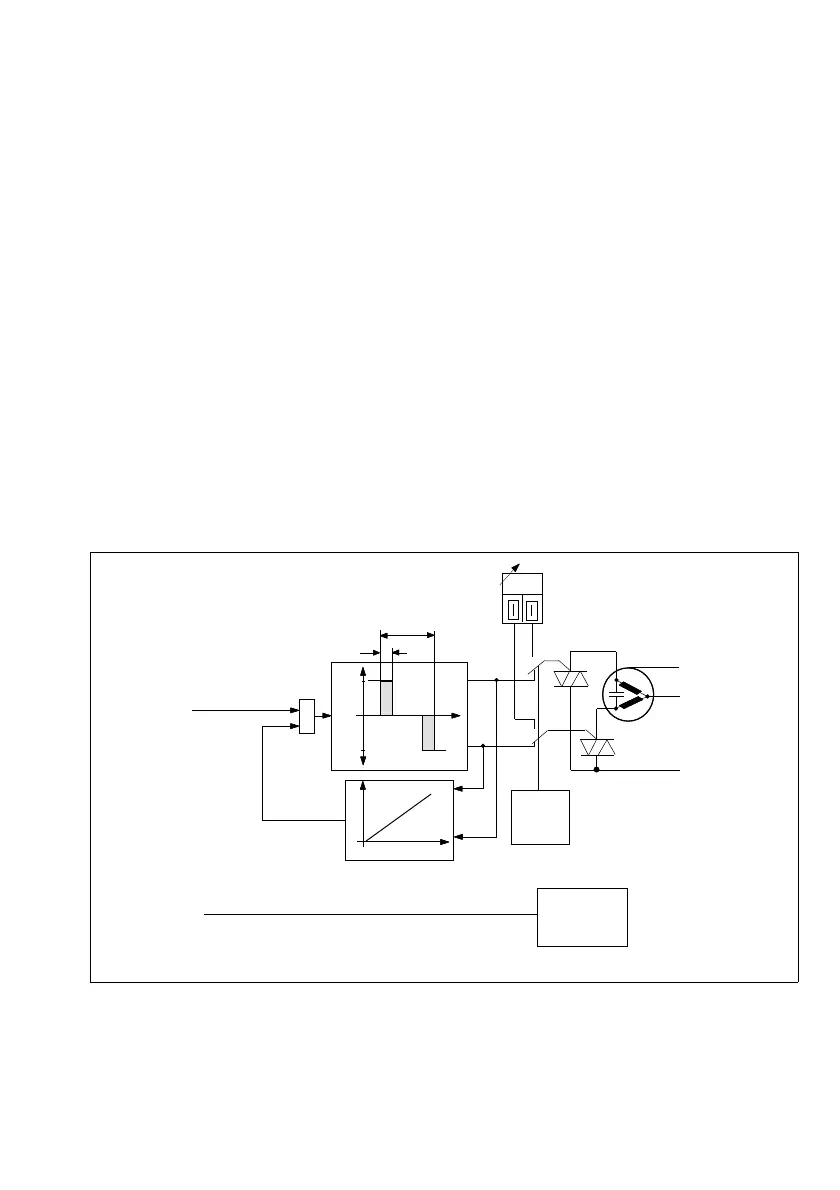

+

_

Y

R

Y

t1

Y

R

Y1

Y2

%

tH

td

L1

PE

N

Y1

Y2

PID

Manual

(from continuous-action

controller section)

Comparator

Internal feedback Motor operating time t1

MANUAL/

AUTOMATIC

key

X-Recorder

0(4) to 20 mA

X-Value for recorder input

Fig. 9 ⋅ Three-step switching

25

Loading...

Loading...