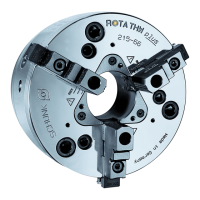

Function

The item numbers specified for the corresponding individual

components relate to chapter drawings.( 9, Page 56)

Principle of Operation

The problem of air supply was solved by a stationary distributor

ring with profile ring seals arranged therein. Openings in the two

elastic radially deformable profile seals allow the compressed air

to flow through a non-return valve to one of the two pressure

chambers. The pilot controlled non-return valve controls the

feeding to one pressure chamber and the simultaneous forced

ventilation of the second pressure chamber. This triggers the

piston stroke and the base jaws are moved by the wedge hook.

The valve system blocks and stores the pressure in the chuck body

while the profile seals, due to their elasticity, are raised from the

chuck body by the ventilation of the supply lines and therefore are

not subject to wear from the rotating chuck.

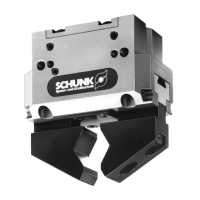

Functional testing

Functional test

After installation of the chuck, its function must be checked prior

to start-up.

Two important points are:

• Clamping Force! The clamping force of the chuck must be

achieved at max. operating force/pressure.

• Stroke control! The stroke of the clamping piston must allow a

safety zone at the front and rear end position. The machine

spindle may only be started when the clamping piston has

passed through the safety zone. Only limit switches that meet

the requirements for safety limit switches specified in DIN EN

60204-1 may be used.

When determining the necessary clamping force to machine a

workpiece, take the centrifugal force acting on the chuck jaws into

account (according to VDI 3106).

If the chuck jaws are changed, adjust the stroke control to the new

situation.

Loading...

Loading...