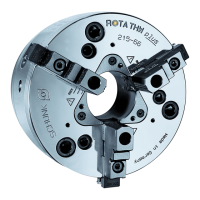

04.00|0889071 ROTA TP / ROTA TP-LH |en

Mounting

Installing and connecting

Risk of injury due to unexpected movements!

If the power supply is switched on or residual energy remains in

the system, components can move unexpectedly and cause

serious injuries.

• Before starting any work on the product: Switch off the power

supply and secure against restarting.

• Make sure, that no residual energy remains in the system.

Danger of injury due to sharp edges and rough or slippery

surfaces

• Wear personal protective equipment, particularly protective

gloves.

Always use the correct length of mounting screws when

mounting the chuck and flange. Screws that are too long may

protrude from the tapping drill hole or damage the machine

spindle.

1 Preparing the mount ( 6.2, Page 35)

2 Chuck assembly ( 6, Page 35)

3 Performing a functional check ( 4.2, Page 29)

Inclusion

For ROTA TP 125 / Z up to 350 / Z lathe chuck types, a normal

intermediate flange must be placed on the spindle head. Using 6

pin screws M12 x 40 (sizes 160 - 350), the rear flange side of the

front of the power chuck which has been turned free is screwed

»across corners« into the intermediate flange which has been

screwed into the spindle head. The cylindrical precisely turned

centering shoulder on the flange must be screwed on 6

−2

mm

deep so as to ensure contact with the outer chuck edge. In order

Loading...

Loading...