Risk of fatal injury to operating personnel if the top speed is

exceeded, resulting in workpiece loss and parts flying off!

• A reliable speed limiter must be installed in the machine tool

or technical equipment and proof must be provided that the

speed limiter is effective!

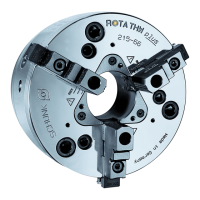

Air transmission system

Air transfer takes place only when the headstock spindle is at a

standstill, via profile seals provided radially in the distributor ring.

The profile seal is designed so that the outer upper section of the

surface is larger than the surface of the openings. Upon

pressurization the difference in surface area exerts a radial force

on the profile seal in the ring-shaped chamber of the distributor

ring, resulting in optimal static sealing of the profile seal at the air

transfer point. This allows low-loss flow of the air through the

openings in the profile seal into the cylinder chamber of the chuck.

If the supply of compressed air is stopped, the double check valve

closes and the pre-tensioned profile seal raises from the chuck

body due to its elasticity and is not subjected to wear during

rotation of the chuck. The off- and return air out of the opposit

cylinder chamber leaves for the most part directly below the

associated profile sealing.

Loading...

Loading...