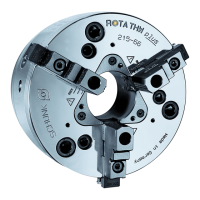

Mounting with 2-part clamping ring (D.R.M.B.)

The distributor ring can be clamped onto a rigid collar on the

machine (at least 8 mm wide) using a two-piece clamping ring. The

distributor ring is clamped onto this collar by two screws. The

height of the clamping ring is designed according to the "Bracket

Mounting" chapter. ( 6.3.2, Page 39).

During assembly, this two-piece clamping ring is first screwed to

the threads of the distributor ring. Then they entire assembly

group is clamped onto the rigid collar of the machine. When

mounting the chuck with a bayonet or Camlock, the clamping ring

should have a cut-out to allow access to the collar nuts or

clamping cams using the corresponding wrench.

NOTE

The distributor ring must be aligned with the outer chuck diameter

in such a way that at least a radial and axial run-out tolerance of

0.1 mm is achieved.

During the assembly, as mentioned at the start, it must be ensured

that the distributor ring is axially and radially aligned with the

chuck body without contact and fixed.

Note

Therefore, ONLY flexible connection cables may be used.

The radial alignment of the distributor ring is correct if the

distance between the distributor ring cover and the distributor

ring equals a (see the "Conventional Mounting of the Distributor

Ring" chapter) ( 6.3.2, Page 39). The ring can be aligned radially

with a feeler gauge. The air gap between the chuck body and the

distributor ring at the front and rear should be uniform over the

entire circumference (approx. 1 mm). Additional measurement

and alignment can be performed by using a magnetic dial indicator

stand, which is placed on the face side of the chuck. The dial

indicator is placed radially against the distributor ring and the

distributor ring is aligned until the dial indicator no longer

indicates a significant deviation (approx. 0.2 mm).

Loading...

Loading...