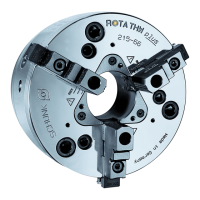

Hardened Reversible Jaws and Soft Top Jaws

Make sure that the top jaws are set for clamping on the fine

serration so that no more than 2/3 of the jaw stroke has to be

extended (clamping reserve).

Hardened reverse jaws may be used only in sets as packaged at

the factory, since they are ground in sets on the chuck. Normally,

one set of hardened reverse jaws is ordered with the chuck. During

assembly and disassembly of the reverse jaws numbered 1 to 3

make sure that the single jaws are paired with the base jaws with

the same numbers in order to achieve good true running

properties.

Turning of the soft top jaws must be performed on the chuck in

the same clamping position and at the same operating pressure

specified for machining of the workpiece.

Hardened roughing jaws whose clamping surfaces have conical

teeth with good grip should be used for rough turning work or

preturned workpieces.

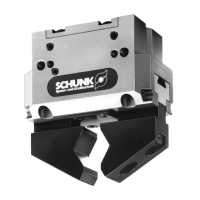

Disassembly

1 Unscrew both pneumatic swivelling elbow screw-fittings from

the distributor ring, remove front-mounted power chuck from

spindle head.

2 After unscrewing the 3 hexagon socket head screws (item 38)

in 3 pieces (item 9, 11, 12), remove the distributor ring

backwards from the chuck.

Note

The chuck is pressurized! It is imperative that the valve sys-

tem (item 18) be removed before any further disassembly!

Loading...

Loading...