Zhejiang Sealand Technology Co.,Ltd.

It is composed of switching power supplier, guard grating, core processor board, display

module, etc, installed in a ex-proof junction box. Switching power supply offers power for the

transmitter; safe grating isolates flow sensor and transmitter intrinsically; core processor

detects & processes sensor phase signal, sends mass flow signal and process

communication.

2.2.1 Main features

● Power≤15W;

● 3 calculators, to count flow rate, density & temperature respectively;

● 2 ways for parameter setting, infrared sensor buttons and software on computer

connected through RS232;

● RS485 port, Modbus protocol(please contact our sales team for detail protocol);

● Pulse signal output is OC door output, which can be connected with electronic totalizer;

● Factory set: 1 pulse signal equals 0.1g, customizable before production.

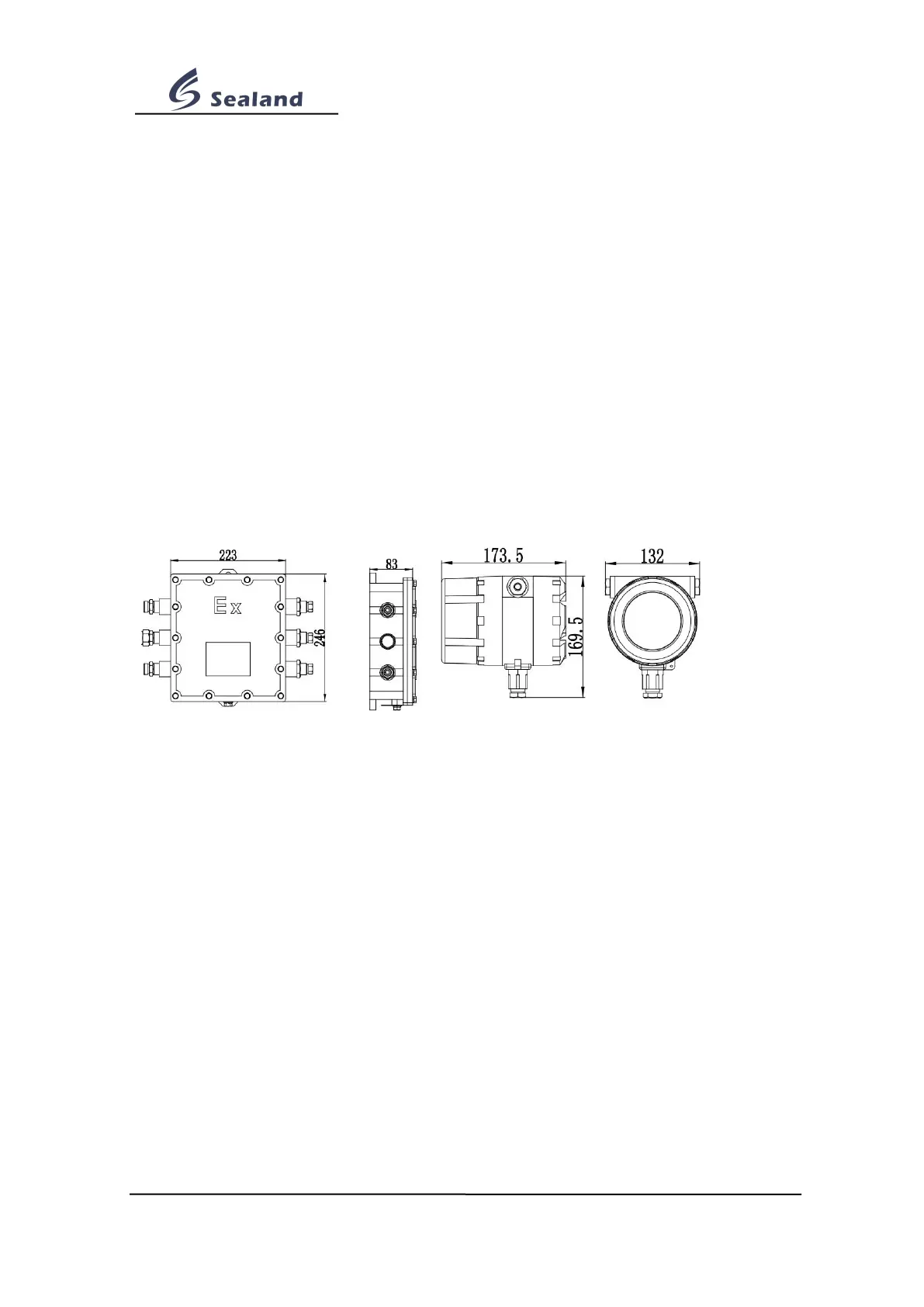

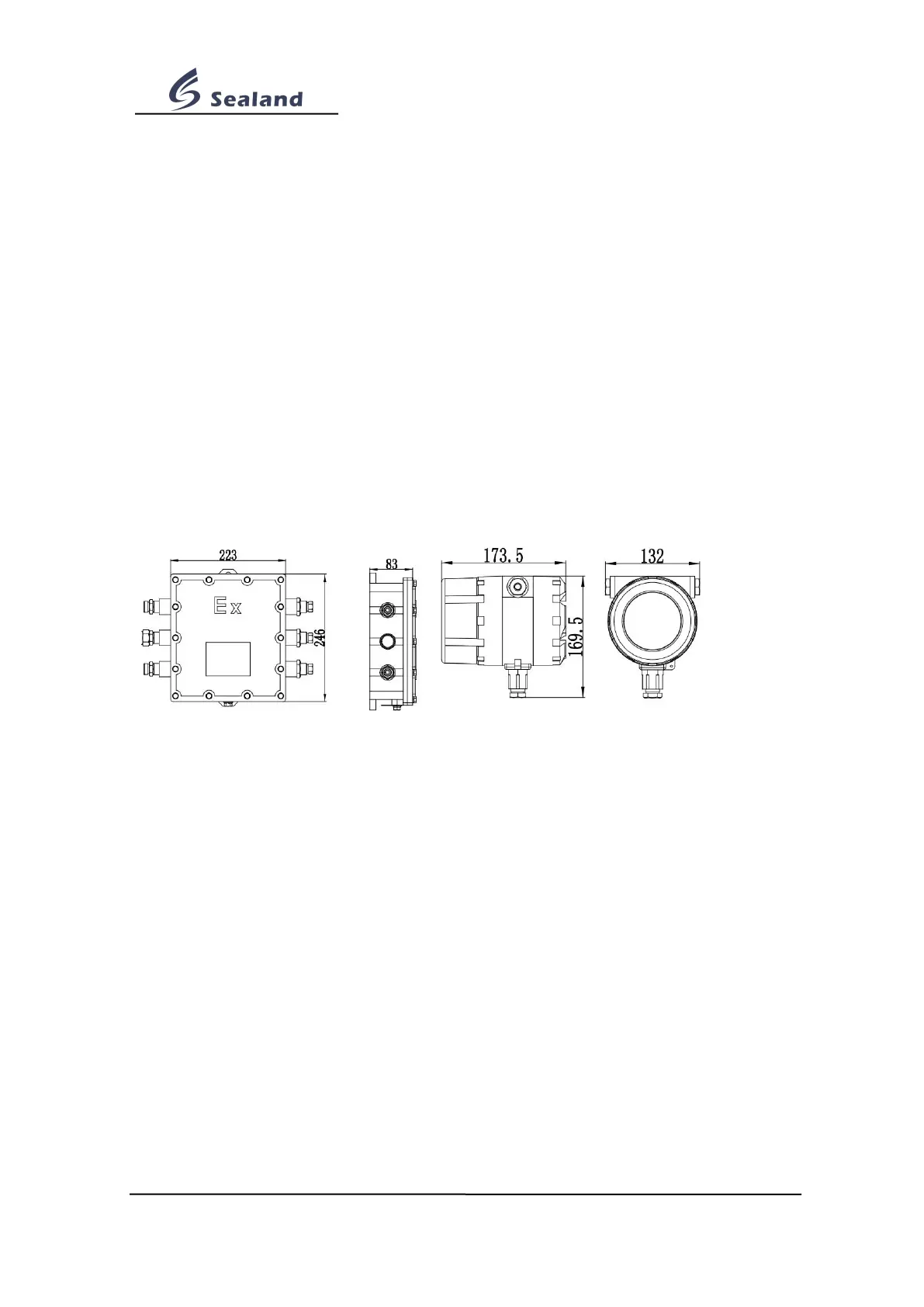

2.2.2 Dimension

There are 2 different configurations, F210 & F23X.

Dimension of F210 Dimension of F23X

Pic 2-2 Dimension of transmitter/mm

Chapter 3 Installation

Please read this manual carefully before installation. Take measure to avoid electric shock,

and connect sensor with pipes correctly, without any leakage. Fluid pressure should be no

more than the value marked on nameplate. It is highly recommended to hire professional

technicians for installation and maintenance.

a) Make sure flange, housing & wire plug undamaged, wiring & wiring board tight and

undamaged, and the model number on nameplate is same as ordered;

b) Choose correct installation site;

c) Install the meter according to direction mark on sensor;

d) Connect transmitter & sensor with 12-pin cable;

e) Start.

Loading...

Loading...