Section 7 Docking Station Technical Io

SENSOR

84

SMT-200 Operations and Technical Manual 2.00/R1

7.2 PC Interface

The SMT-200 is connected to the docking stations Centronics 24 way connector (J1) . The geophone

sockets on the docking station, the Smartec RJ-11 (JP3) and the output of battery charger #1 connect

directly to J1. The PC’s handshake signals also connect directly to J1.

The Data Terminal Ready (DTR) line has a secondary function. When active it will switch the SMT-200

on. When DTR is asserted the mosfet Q1 will conduct and toggle the power on flip flop in the

SMT-200.

7.3 Battery Charging

There are two totally independent charging circuits built around U6 and U7. These devices are

UC3906 sealed lead acid battery charger IC’s. These controllers contain the necessary circuitry to

optimally charge sealed lead acid batteries. These type of batteries have specific charging

requirements so the SMT-200 batteries should only be charged on the docking station.

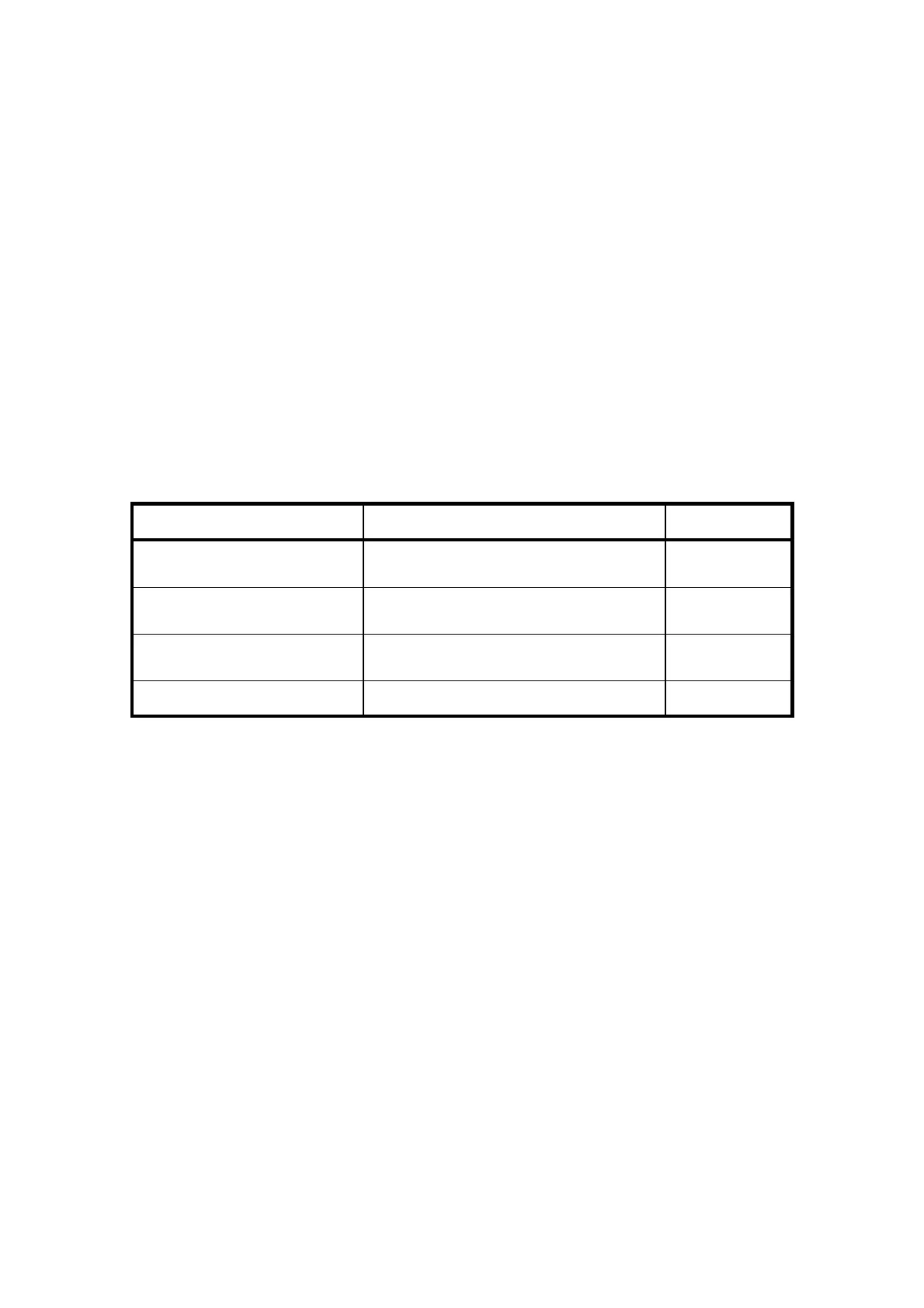

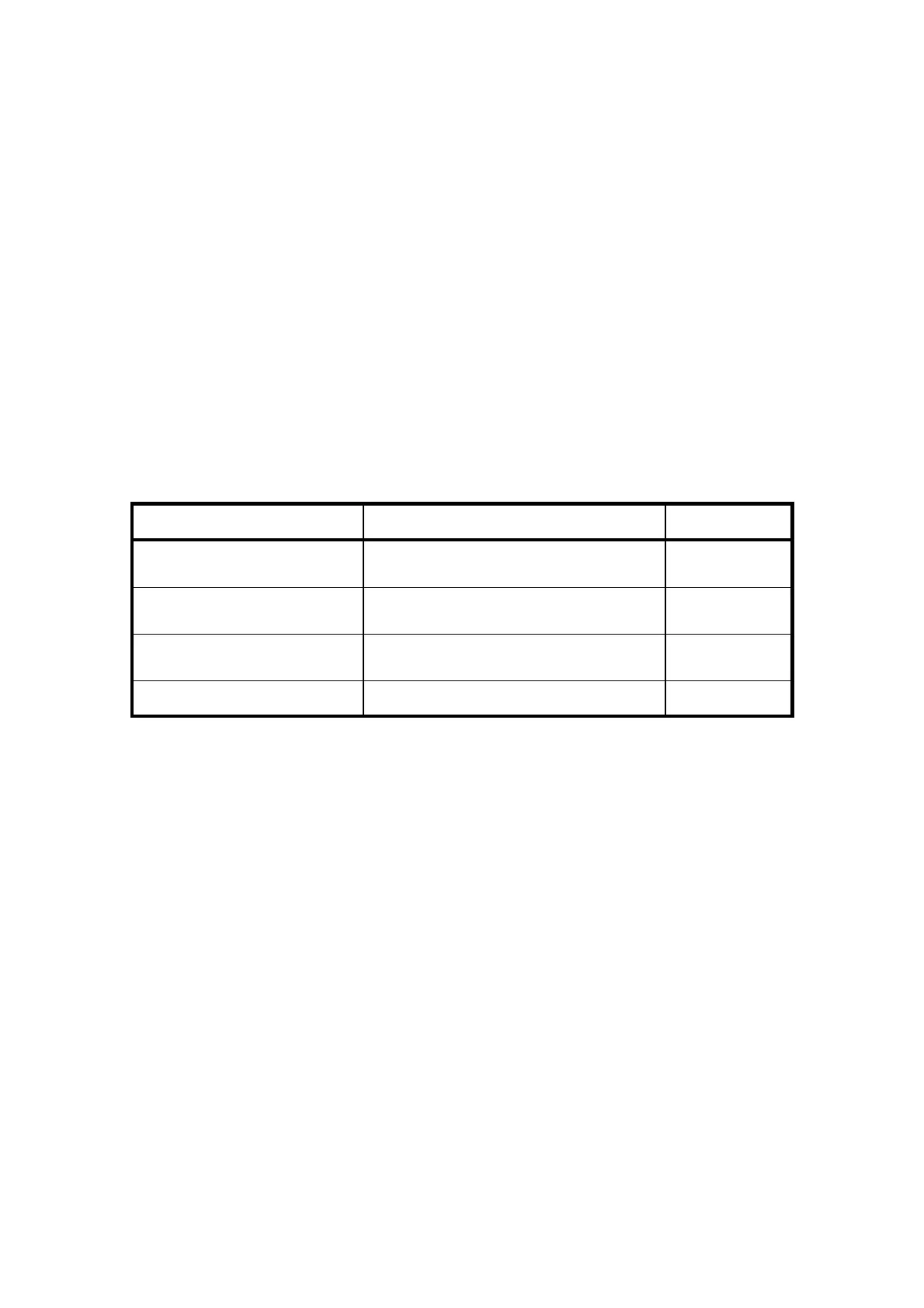

There are four basic states the charging circuit will assume (see table below).

STATE DESCRIPTION LED COLOUR

1

Low Current Turn on

Very small current. Checks for dead or

disconnected battery.

off

2

Bulk Charge

High current to minimise charging

time.

RED

3

Controlled Overcharge

Battery V and I monitored to prevent

overcharging

ORANGE

4

Precision Float Charge Trickle charge (same as State 1) GREEN

The dual colour LED has a green and red LED. If both are on at the same time the LED will ap`pear

orange in colour.

The two charging circuits are similar. Battery charger #1 has some additional circuitry that

compensates for the extra current the SMT-200 draws when connected to the charger.

Looking at Charging Circuit #2, when the battery is first connected it starts to charge by the current

flowing through R23. If the battery is shorted this will limit the current to a safe level. Once this current

has caused the battery voltage to increase above a preset threshold the charger will switch to State 2

(Bulk Charge) and continue to charge the battery until the battery voltage rises to 95 % of the Over

Charge voltage. At this point the charger will switch to State 3, the Controlled Overcharge state.

During State 2 and State 3 the Over Charge Terminate pin of U7 (pin 8) is low turning on Q7 and the

red LED. It will continue charging until the current drops to 10% of the maximum current supplied

during State 2 (about 500 mA). At this point the charger will assume State 4 (the trickle charge state)

where the battery is floated via the current flowing through R23. Pin 8 of U7 will now turn the red LED

off.

The green LED is turned on via Q9 and Q8. The transistor Q8 is will turn the LED on (via Q9) when

sufficient current flows through D6 providing pin 10 of U7 is high. If pin 10 is low (as it is during State 1

and 2) Q8 will not conduct regardless if Q11 is on or off preventing the green LED from illuminating.

The Charger #1 (SMT-200) is very similar with the addition of a relay. Relay K1 will energise when the

SMT-200 is switched on, adding R16 into the circuit. The effect of this to the change the point the

Loading...

Loading...