DESCRIPTION AND FUNCTION OF COMPONENTS

OVEN LAMP

The oven cavity lamp illuminates the interior of the oven

so that the food being cooked can be examined visually

through the door window without having to open the

door.

COOLING FAN MOTOR

The cooling fan motor drives a blade which draws cooling

air through the oven base. This cooling air is directed

through the air venes surrounding the magnetron and

cools the magnetron assembly. Most of the air is then

exhausted directly through the back vents. However, a

portion of this air is channeled through the cavity to

remove steam and vapors given off from the heating foods.

It is then exhausted at the top of the oven cavity into a

condensation compartment. This fan motor operates

during both microwave and convection cooking.

TURNTABLE MOTOR

The turntable motor rotates the turntable located on the

bottom of oven cavity, so that it works to cook the foods

on the turntable evenly, during both microwave and con-

vection cooking.

THERMISTOR

The thermistor of negative temperature coefficient type.

The temperature in the oven cavity is detected through

the resistance of the thermistor, and then the control unit

causes the heater relay to operate, thus the current to the

heating element is turned ON/OFF.

MAGNETRON THERM0 CUT-OUT

The

therm0

cut-out located on the magnetron assembly,

is designed to prevent damage to the magnetron if an

overheated condition develops in the tube due to cooling

fan failure, obstructed air ducts, dirty or blocked air intake,

etc. Under normal operation, the

therm0

cut-out remains

closed. However,

when abnormally high temperature

within the magnetron approaches a critical level, the

therm0 cut-out will interrupt the circuit to the power trans-

former, and will interrupt the cook cycle. When the

magnetron has cooled to safe operating temperature, the

therm0

cut-out closes and the cook cycle will resume.

COOK RELAY

The cook relay is mounted on the front portion of the

relay chassis.

The coil of the cook relay is energized by the control unit

and relay unit, thereby closing its contacts which provide

a current path to the power transformer.

The cook relay is activated by 12 volts D.C. supplied from

control unit and relay unit.

HEATER RELAY

The heater relay is mounted on the back portion of the

relay chassis.

The coil of the heater relay is energized by the control

unit and relay unit, thereby closing its contacts which

provide a current path to the heating element.

The heater relay is activated by 12 volts D.C. supplied

from the control unit and relay unit.

STOP SWITCH

The stop switch is located on the open device of the

control panel assembly and activated by the door lever.

When the open button is depressed while the oven is in

cook cycle (microwave or convection cooking), the stop

switch contacts open to de-energize the shut-off relays

and cook or heater relay circuit in the control unit and

relay unit.

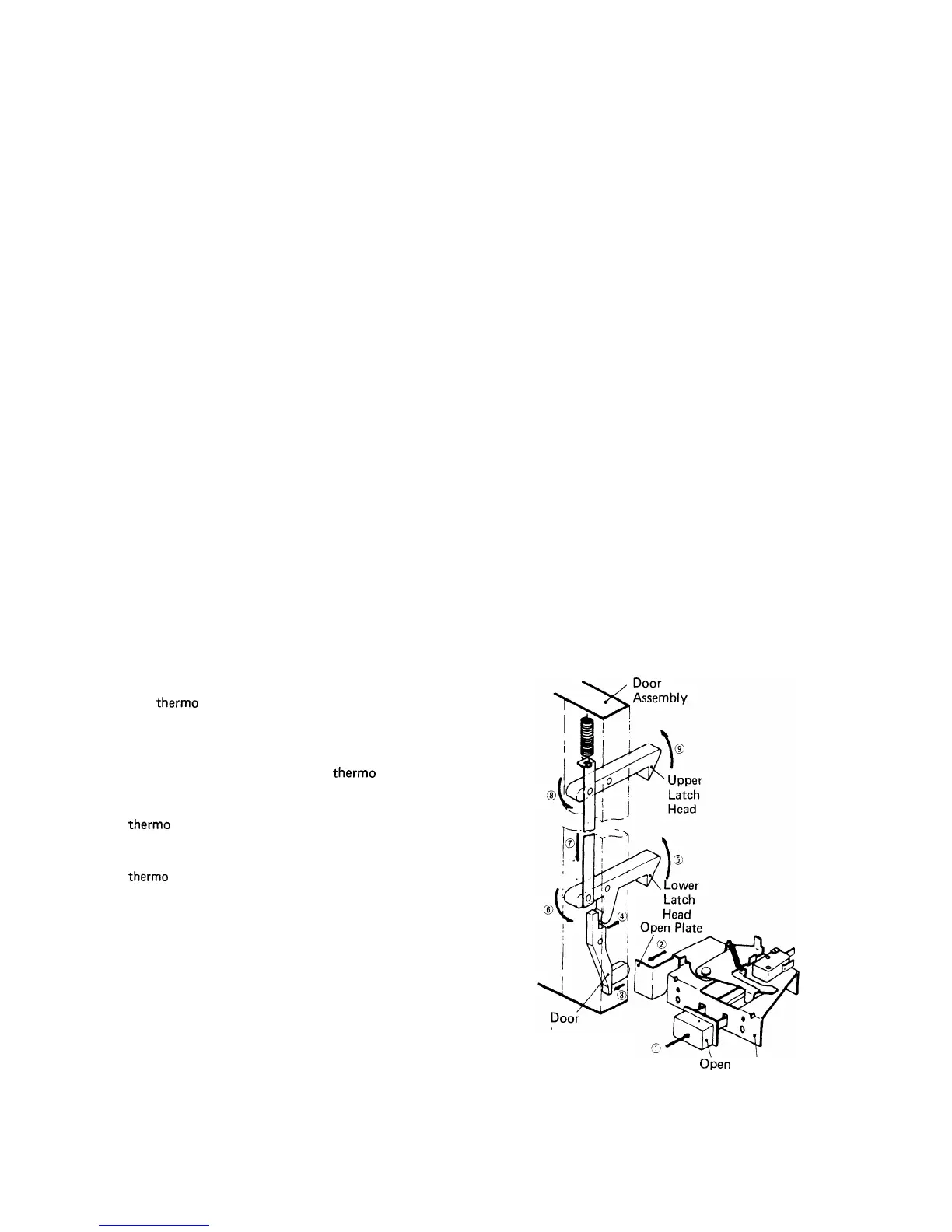

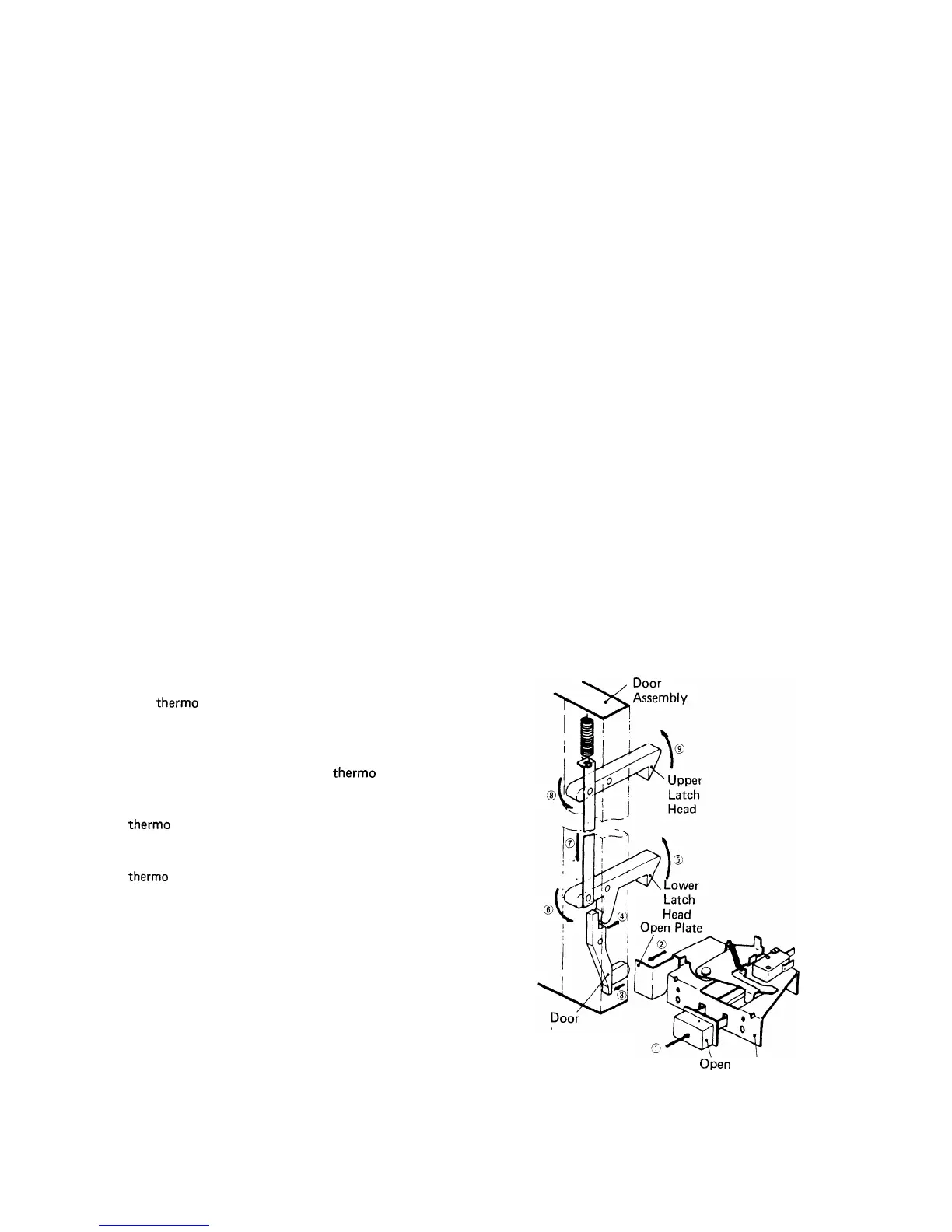

DOOR OPEN MECHANISM

The door can be opened by pushing the open button on

the control panel, refer to Figure 7.

When the open button is pushed, the open plate on the

open device pushes in the door lever on the door, operat-

ing the latch head linkage. The lower and upper latch

heads are moved upward, and are released from the lower

and upper latch hooks.

Now, the door can be opened.

Lever

Open

Open

Button Device

Figure 7 Door Open Mechanism

44

Loading...

Loading...