CHECKER

The checker is used when repairing or adjusting the touch

control panel assembly and relay unit.

When connectors coming from the checker are connected

to respective connectors on the control panel components

or relay unit, A.C. power can be supplied from checker

(including relay unit) to control panel components so that

the panel components can be operated, being separated

from the oven circuit electrically.

Use of Checker

a) for repairing

b)

for executing test program

“Test Program” is executed by using the checker.

Connection Method

Control Panel Assembly:

1. Connect the 1 l-pin connector

@

to the control

unit.

2. Connect the

2-pin

connector

@

(for stop switch)

to the control unit.

3. Connect the

5-pin

connector

@

(for damper

switch and thermistor) to the control unit.

Relay Unit:

1. Connect the

2-pin

connector

@

(for stop switch)

to the New control unit.

2. Connect the

5-pin

connector

@

(for damper

switch and thermistor) to the New control unit.

3. Connect the

5-pin

connector

@

to the de-

fective relay unit.

4. Connect the 1 l-pin connector

@

of defective

relay unit to the New control unit.

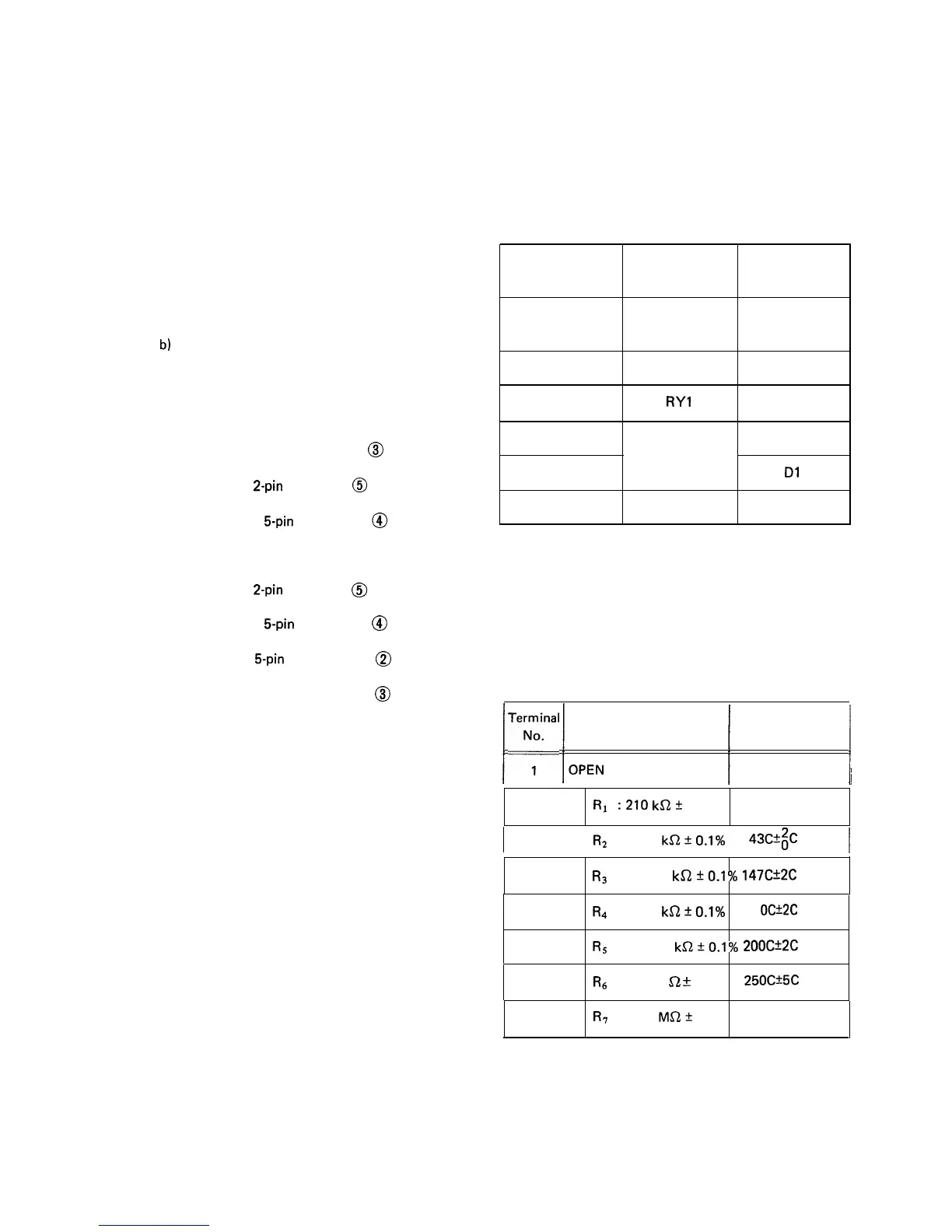

Table 1 shows the relation between the indicator lamps of

the checker, energized relays of the relay unit, and LSI

(I-1 ) signals.

Table 1

INDICATOR

OPERATIONAL SIGNAL

LAMP

RELAY

FROM LSI (l-l)

Oven Lamp

RY2

D2

Turntable Motor

Cooling Fan Motor

Convection Motor

Heater

Cook

Damper

RY3

RYl

Operates at

12V D.C

RY4

D4

DO

D3

Dl

D5

Note: The damper- indicator light is turned on or off by

the damper motor and damper switch in the checker.

Damper indicator light on: Damper is open posi-

tion

Damper indicator light off: Damper is closed posi-

tion

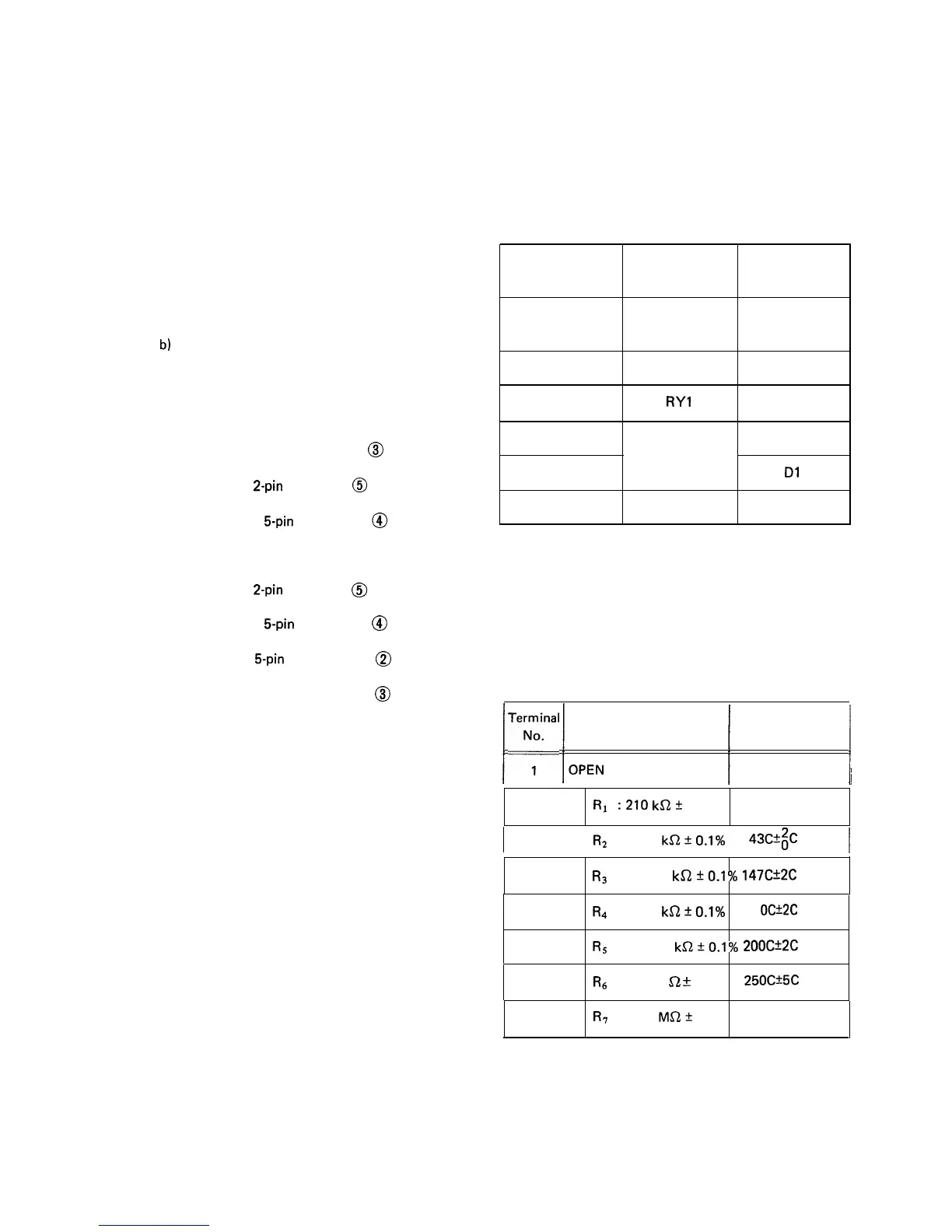

SENSOR DUMMY RESISTANCE

1

Terr:

1

OPEN

ResistanceDisplay Value

1

1

2

Rl

:210

ka2

1% LOC

I

3

R2

: 30

ka*O.l%

43c+

I

4 --

R3

: 6.1

kKZ

+O.l%

147C+2C

5

R4

: 4

kQ*O.l%

11

OCk2C

6

R5

: 1.7

kQ20.1%

200C*2C

7

R(j

: 400

$2

rt

0.1%

25OCX5C

8

R7

:

1

MQ2+

1%

Open judge

80

Loading...

Loading...