28

(2) Conditions that cancel soft start

c

When soft start time has elapsed normally.

d

When output values of soft start are higher than PID operation output values.

e

When soft start time is changed to OFF.

f

When switched to manual mode.

g

When AT (auto tuning) is executed.

h

When P (proportional band) is changed to OFF.

i

When control output characteristics are changed.

j

When in standby mode.

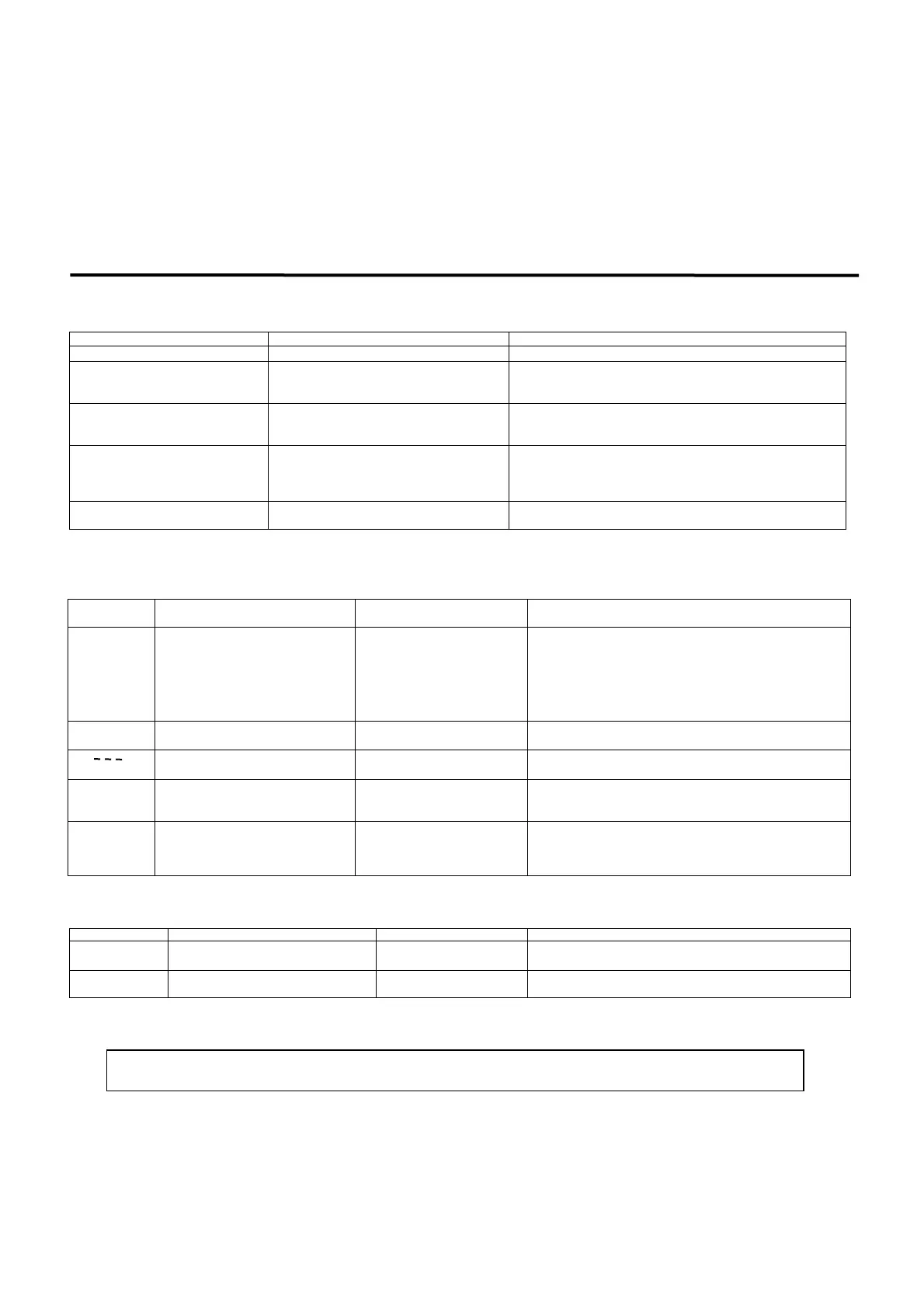

9. Causes and remedy of trouble and errors

9-1. Causes and remedy of trouble

Problem Cause Remedy

c

Error message is displayed.

See “Causes and remedy of errors.” See “Error Codes, Causes and Remedies.”

d

Displayed measured value (PV) seems to

be incorrect.

c

Set measuring range code is different from that of

input sensor / input signal.

d

Erroneous wiring to input terminals of sensor.

c

Check if set measuring range code is correct for input signal.

d

Cortect wiring to input terminals of sensor.

e

Front panel display goes off and does not

function.

c

Problem with power supply and/or wiring

connection.

d

Something is wrong with the instrument.

c

Inspect power supply / wiring connections and check wiring.

d

Inspect, repair or replace the instrument.

f

Keys do not work.

c

Key lock is in effect.

d

Communication is set to Com during

communication.

e

Something is wrong with the instrument.

c

Cancel key lock.

d

Set communication to local (Loc).

e

Inspect, repair or replace the instrument.

g

ON-OFF action of control output is too

fast.

c

ON-OFF “hysteresis range is too narrow. ”

c

Widen ON-OFF “hysteresis range. ”

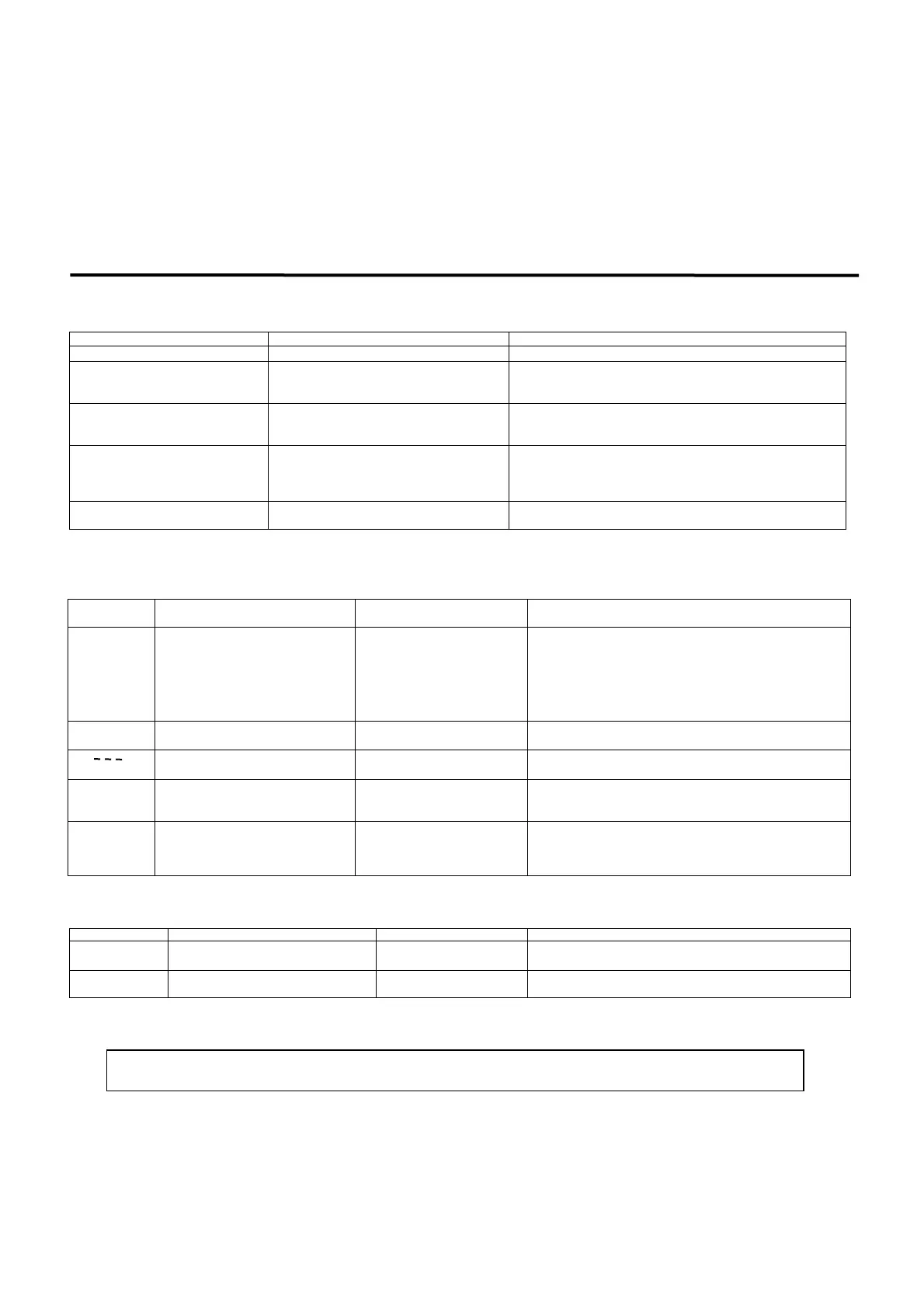

9-2. Causes and remedy of errors

(1) Abnormal measured input

Screen

display

Problem Cause Remedy

(HHHH)

Higher limit scaleover

c

Break in thermocouple input

wiring.

d

Break in R.T.D. input A wiring.

e

Input measured value exceeded

higher limit of measuring range

by 10%.

c

Check thermocouple input wiring for possible break. If there is

nothing wrong with wiring, replace thermocouple.

d

Check R.T.D. input A terminal wiring for possible break.

If there is nothing wrong with wiring, replace R.T.D.

e

For voltage or current input, check the measurement signal

transmission unit.

Check if set measuring range code is correct for input signal.

(LLLL)

Lower limit scaleover

Input measured value fell below lower

limit of measuring range by 10%.

Check for measurement input wiring for reverse polarity or possible

break.

(b- - -)

Break in R.T.D. input wiring

c

Break in B wiring

d

Multiple break in ABB wiring

Check R.T.D. input ABB terminal wiring for possible break. If there

is nothing wrong with wiring, replace R.T.D.

(CJHH)

Higher limit scaleover of cold junction (CJ)

of thermocouple input

Ambient temperature has exceeded

80°C.

c

Reduce ambient temperature to the level provided in the environment

conditions for the product.

d

If ambient temperature has not exceeded 80°C, examine the controller.

(CJLL)

Lower limit scaleover of cold junction (CJ)

of thermocouple input

Ambient temperature has fallen

below -20°C.

c

Raise ambient temperature to the level provided in the environment

conditions for the product.

d

If ambient temperature has not fallen below -20°C, examine the

controller.

(2) Heater break/loop alarm errors

Screen display Problem Cause Remedy

(HbHH)

Heater current sensor CT input value has

exceeded 55.0A.

Excessive current

c

Reduce the current.

d

Inspect the controller.

(HbLL)

Something is wrong with the instrument. Something is wrong with the

instrument.

Inspect, repair or replace the instrument.

When the controller does not operate as intended and you suspect it may be broken, read the instruction manual and inspect once again. If there is something

wrong with the controller or there is something you do not understand, contact your nearest Shimaden dealer.

Loading...

Loading...