Mark VII Restored Manual - V1.02 – Donated without cost to the world-wide Shopsmith Community - Everett L. Davis 2016 27

HOW TO USE THE DRILL PRESS

SETTING UP

Raise table to highest point and tilt to the left until two stop screws (No.

21, Fig. 26) underneath table rest on tubes. Secure setting with table tilt

locks and use a square to check the angle of the table to the way tubes. If

it is not exactly 90 degrees, the two stop screws must be adjusted so they

will serve as automatic stops. Use the Allen wrench and thread the screws

in or out until the angle is correct. This check should be made the very

first time you set up SHOPSMITH MARK VII in vertical drill press position.

Lock the carriage at a point about 15 inches from right end. Lock the

headstock so that there is about 10 inches between spindle and table.

BE SURE BOTH HEADSTOCK AND CARRIAGE ARE LOCKED SECURELY.

Lift up left hand trunnion lock lever and then, gripping tubes behind

headstock, lift SHOPSMITH to vertical position. Lock safety latch.

Position of headstock and carriage on tubes may be varied to give most convenient working level relative to

operator’s height.

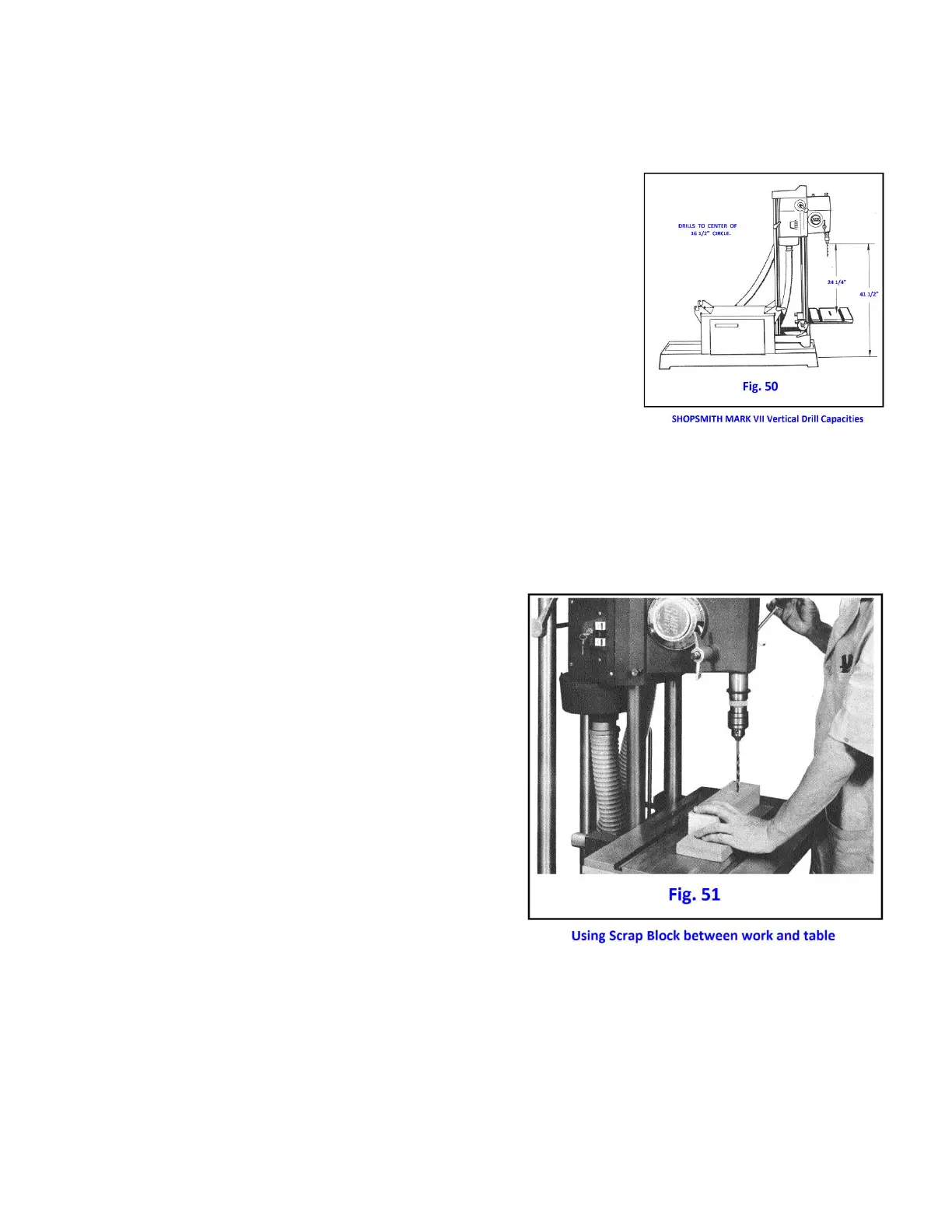

DRILLING

Drill bits and other cutting tools (except those which

require special chucks because of side thrust) are

secured in the Jacobs three-jaw chuck with the chuck

key. BE SURE TO REMOVE THE KEY BEFORE TURNING ON

THE MOTOR. Before drilling, check the speed chart for

correct rpm. Always use a scrap block between the work

and the table (Fig. 51).

Quill feed should be steady so the drill will always be

cutting. On very deep holes it is good practice to retract

the drill frequently to clear chips from the hole.

It should never be necessary to force the drill. If it isn't

cutting cleanly, smoothly and easily, you may be using

the wrong speed or a dull drill.

When drilling metal or large holes in wood be sure to

clamp the work to the table. A drill can catch in the hole,

especially when breaking through, and twist the work

out of your hands.

Loading...

Loading...