Mark VII Restored Manual - V1.02 – Donated without cost to the world-wide Shopsmith Community - Everett L. Davis 2016 44

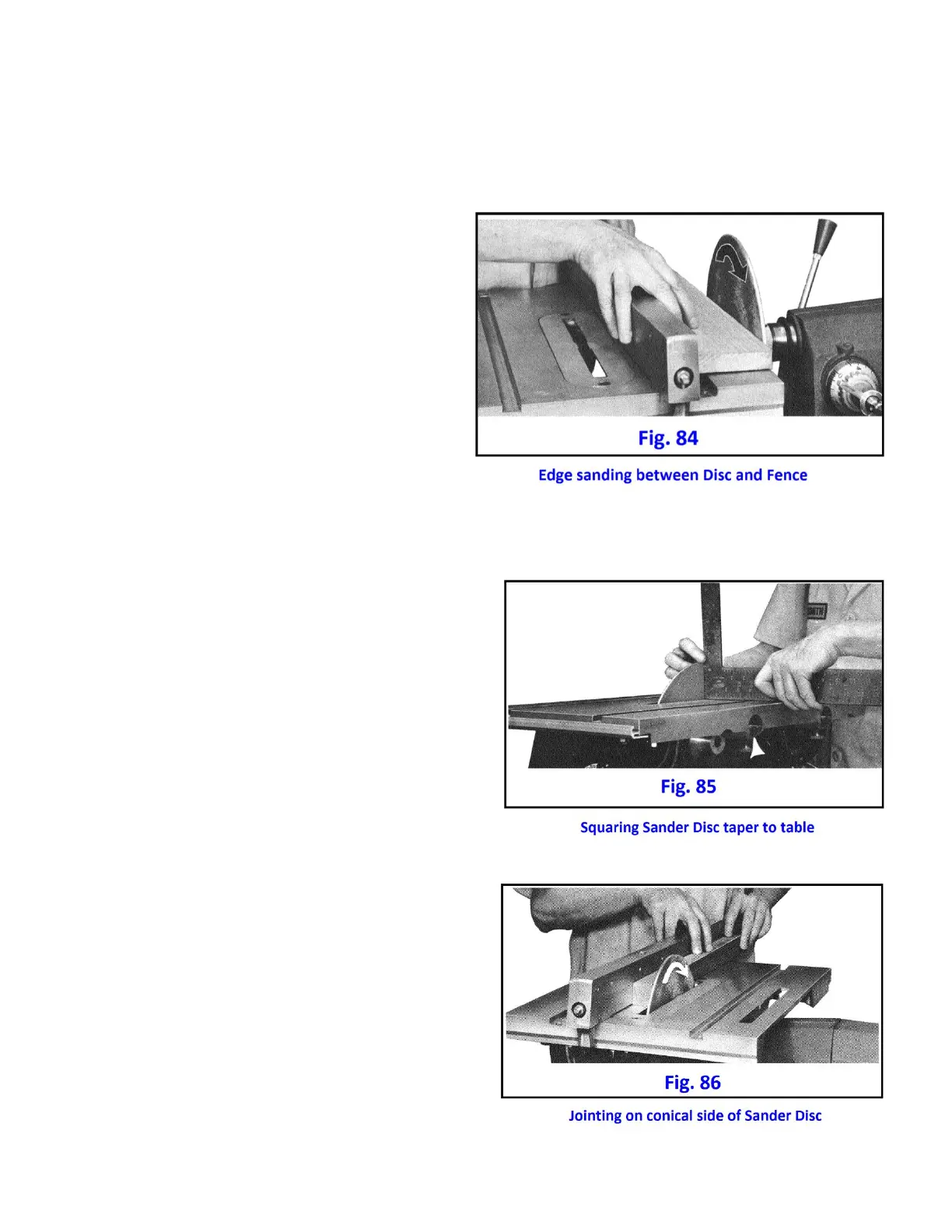

JOINTING ON DISC SANDER - FLAT SIDE

Long straight edges are sanded smooth and

square in an operation that combines sanding,

jointing and finishing to exact width. Use angling

screw (No. 2, Fig. 25) to set the rip fence at a

slight angle to the disc. The distance from fence

to disc should be slightly less than the width of

the work piece. Angle of the fence should be such

to allow contact from outer edge of the disc to

just short of the center. With forward rotation

of spindle work is fed through FROM THE BACK

toward the front of the table while contact is

maintained with the fence throughout the pass.

Can also be setup for feed from the front if

spindle is operated in reverse (Fig. 84). As always,

work slowly - do not force the cut. This setup is a very practical method of jointing plywood.

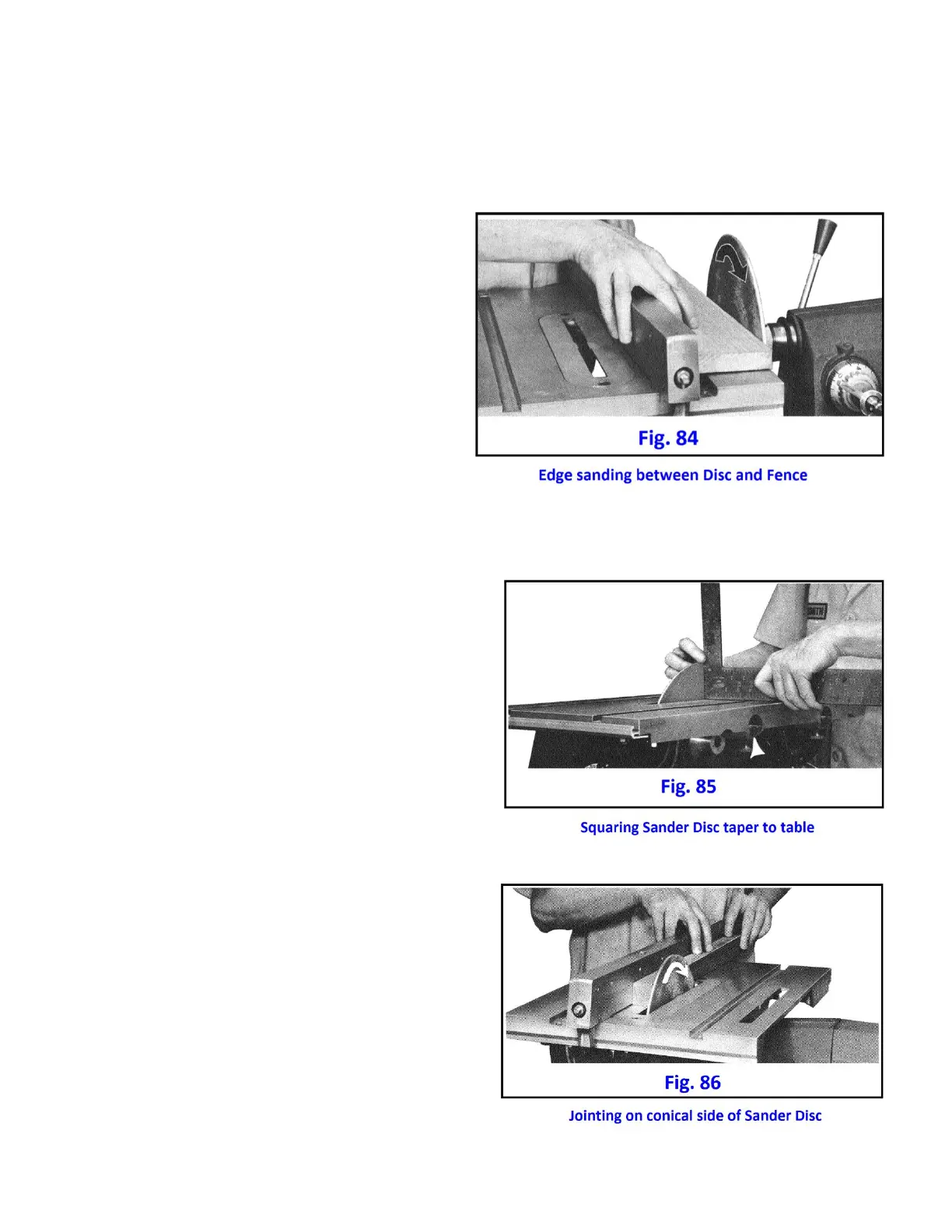

JOINTING ON DISC SANDER-CONICAL SIDE

1. Square table to taper of conical side of disc. (Fig.

85)

2. Use the fence in normal parallel position for a

guide. Determine work dimension by measuring

between center line of sander disc and fence. Work is

fed through against the rotation of the sander disc.

DRUM SANDER

The drum will sand inside and outside curves and

internal circular cutouts with a speed and efficiency

impossible to achieve with any other means. The

special shaper insert is used with the drum sander to

give support in the area immediately surrounding the

drum.

SANDPAPER

Sandpaper, in disc form for the disc sander and in

sleeves for the drum, is available in course, medium

and fine grits. Paper for 10" disc has score mark for

removal of center piece for hub clearance on conical

side.

Loading...

Loading...