Mark VII Restored Manual - V1.02 – Donated without cost to the world-wide Shopsmith Community - Everett L. Davis 2016 46

ALL METAL SURFACES: An occasional application of paste

wax, rubbed to a polish will keep the machine clean, protect the

metal, and allow work to slide more smoothly.

OILING PROCEDURE

SLIDING SHEAVES for SHOPSMITH MARK VII

The SHOPSMITH MARK VII speed changer relies on sliding

sheaves to increase or decrease diameters of driving and driven

pulleys for changing speed. These are precision, close-fit parts

that require oiling for smooth movement of sliding sheaves.

GENERAL: Apply oil, as per directions, about every ten hours of

actual running time. Before oiling, turn Speed-Dial to "Rout-

Shape" range. Turn off switch and unplug cord. Use good-

quality machine oil (SAE 10 weight). Special oil can is not

required. Merely dip a wire or slender stick in oil and allow a

few drops (about three) to drip into holes described.

After oiling start machine and operate through complete speed

range several times.

OILING INTERMEDIATE SHAFT

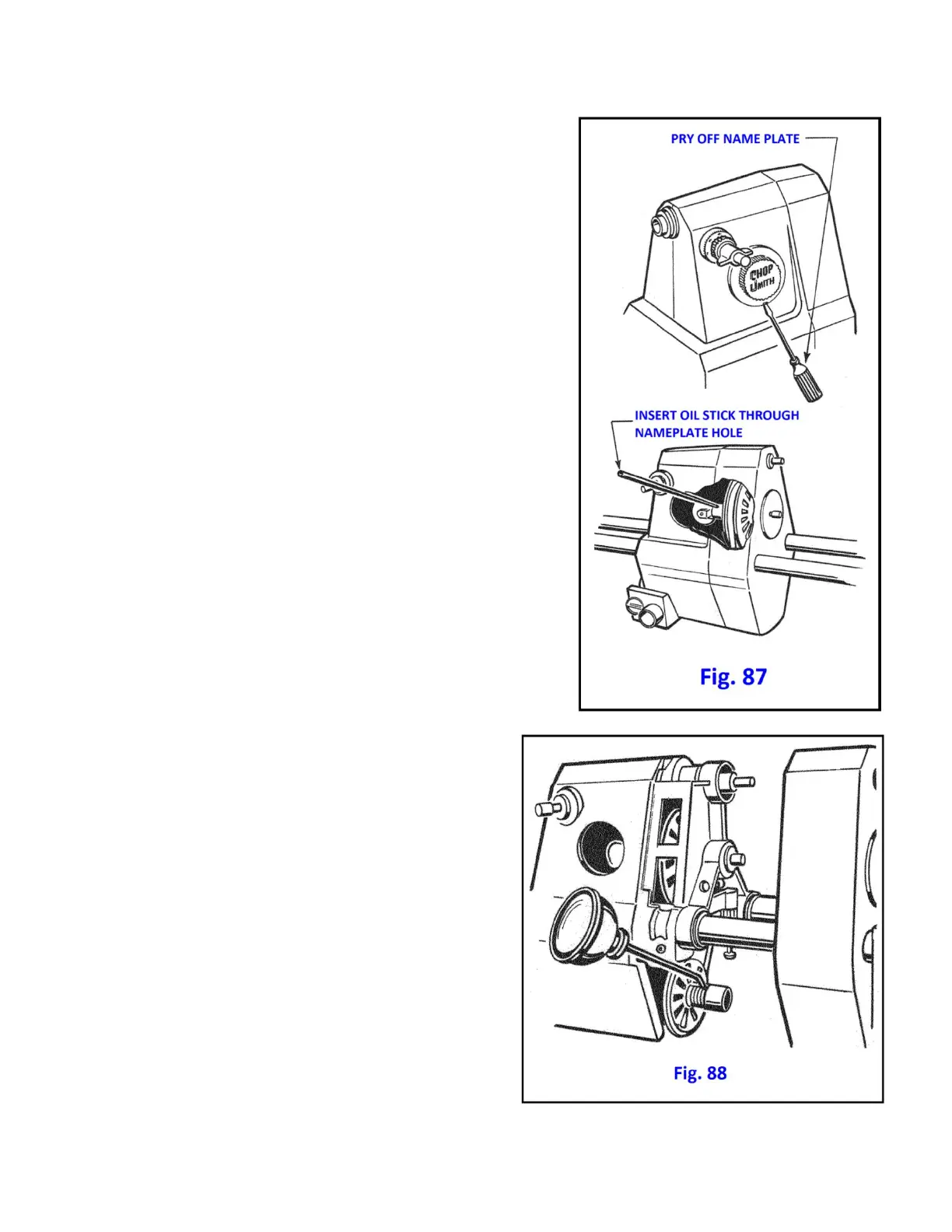

(Fig. 87) Remove nameplate on back of headstock by prying

with screwdriver in notch at bottom of metal escutcheon plate

(like removing a hub cap). Hand turn spindle until hole in sheave

hub can be seen. Place about three drops of oil in hole. Replace

nameplate by pressing it on.

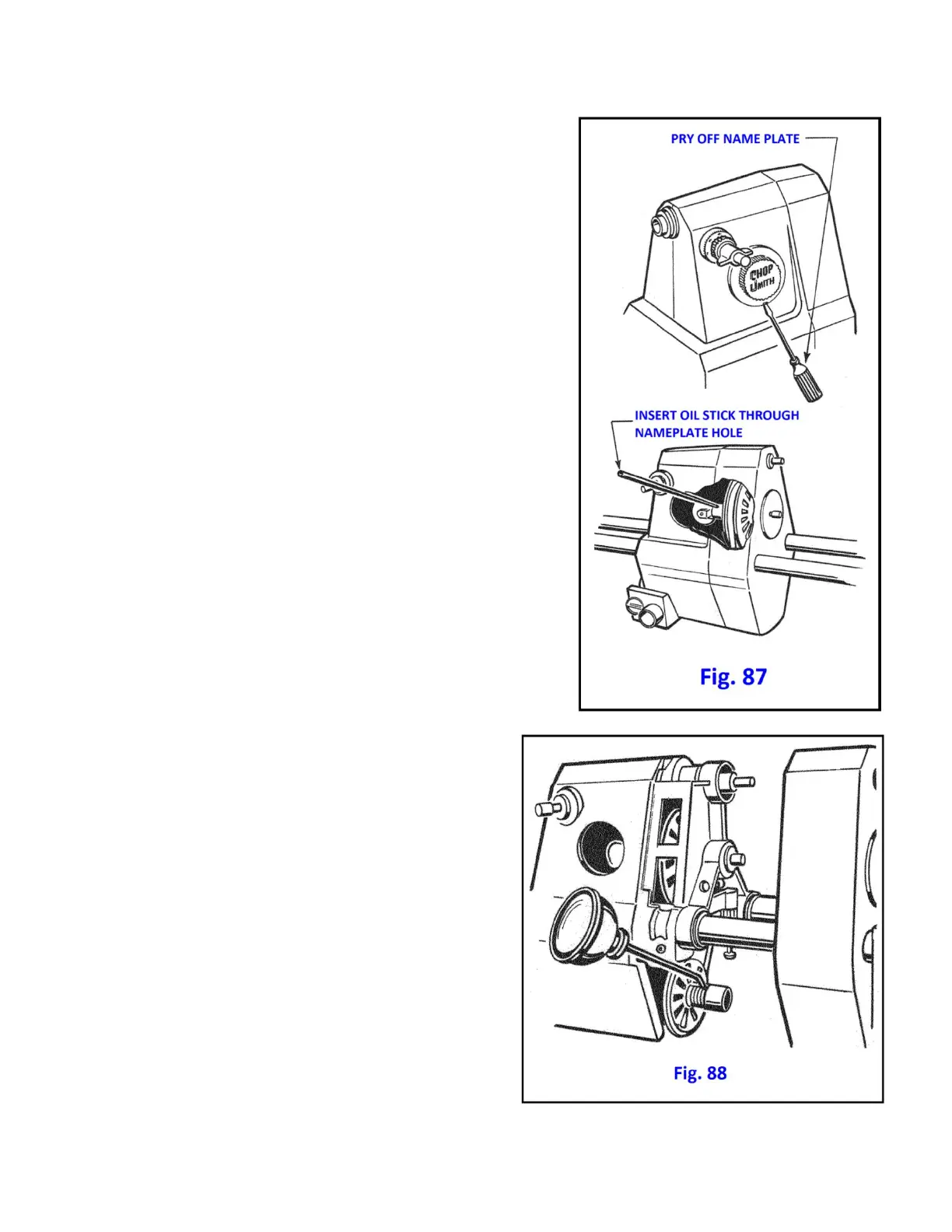

OILING MOTOR SHAFT (Fig. 88) Remove screws

holding Belt Guard to headstock and slide guard along

tubes, away from the unit. Hand turn spindle until hole

in sleeve hub can be seen. Spread coils of spring with

screwdriver and place about three drops of oil in hole.

Replace Belt Guard.

IMPORTANT-Remember to Oil about Every Ten Hours

Actual Running Time.

Loading...

Loading...