Mark VII Restored Manual - V1.02 – Donated without cost to the world-wide Shopsmith Community - Everett L. Davis 2016 38

MOUNTING SPINDLE WORK

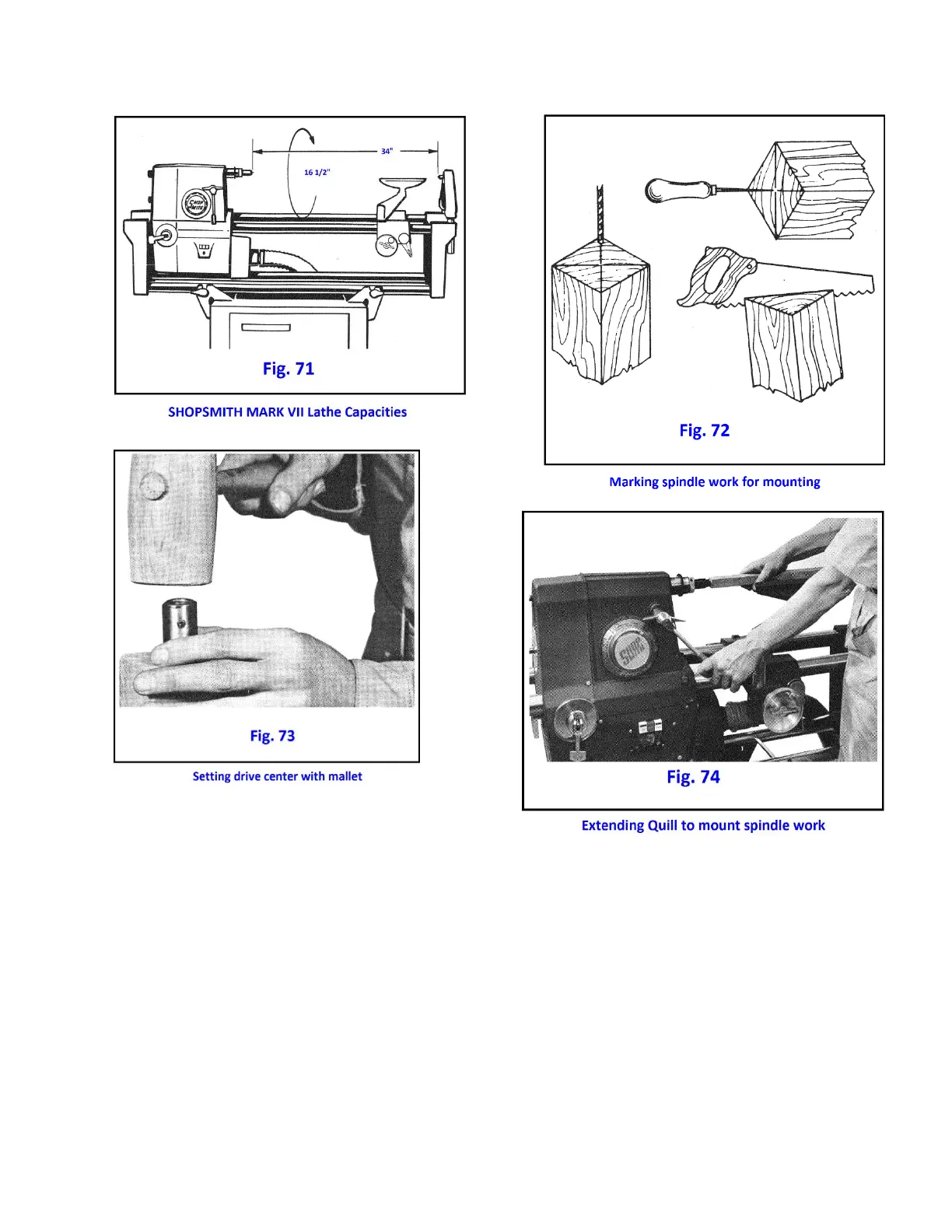

Stock for spindle turning is usually cut square before it is mounted. , Next step is to draw intersecting diagonals

across each end of the stock. (Fig. 72) For soft wood use an awl to form a small hole at each intersection. For

hardwood or plastics drill 3/16" diameter hole for tailstock cup center point and make shallow saw cuts for spurs

of drive center.

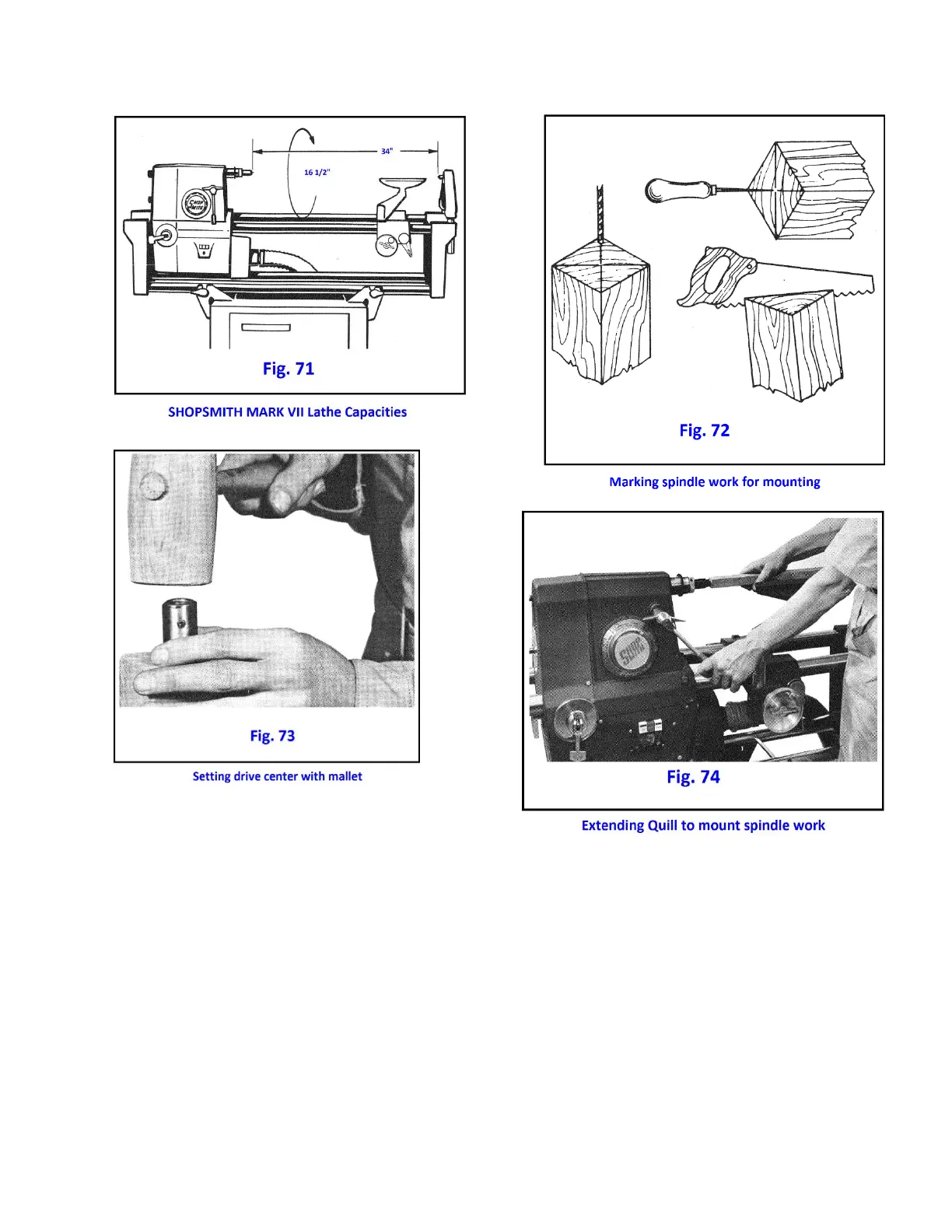

Seat the drive center at one end of the stock by tapping it in place with a mallet (Fig. 73). Place one end of the

stock against the cup point and bring up the headstock so that the drive center, which you have attached to the

spindle, is about 1/4" away from the other end of the stock. Lock the headstock and advance the quill to engage

the work. (Fig. 74) Press the spur solidly in place and then retract the quill enough to smear some beeswax or

tallow on the cup center point and cup, in order to eliminate binding and burning of the wood at the cup point.

Advance quill again, reseating centers lightly but firmly LOCK QUILL.

Machine oil or cup grease on the stationary center will prevent burning but will stain the work.

Loading...

Loading...