Mark VII Restored Manual - V1.02 – Donated without cost to the world-wide Shopsmith Community - Everett L. Davis 2016 33

SHOPSMITH HORIZONTAL DRILL

SHOPSMITH gives you the only adequate horizontal drill press available in the home workshop field. Properly

utilized it will facilitate many operations which are time-consuming, inconvenient, or actually impossible on a

vertical drill press.

HOW TO USE THE HORIZONTAL DRILL

The following are but a few examples which typify operations best handled in horizontal drill press position.

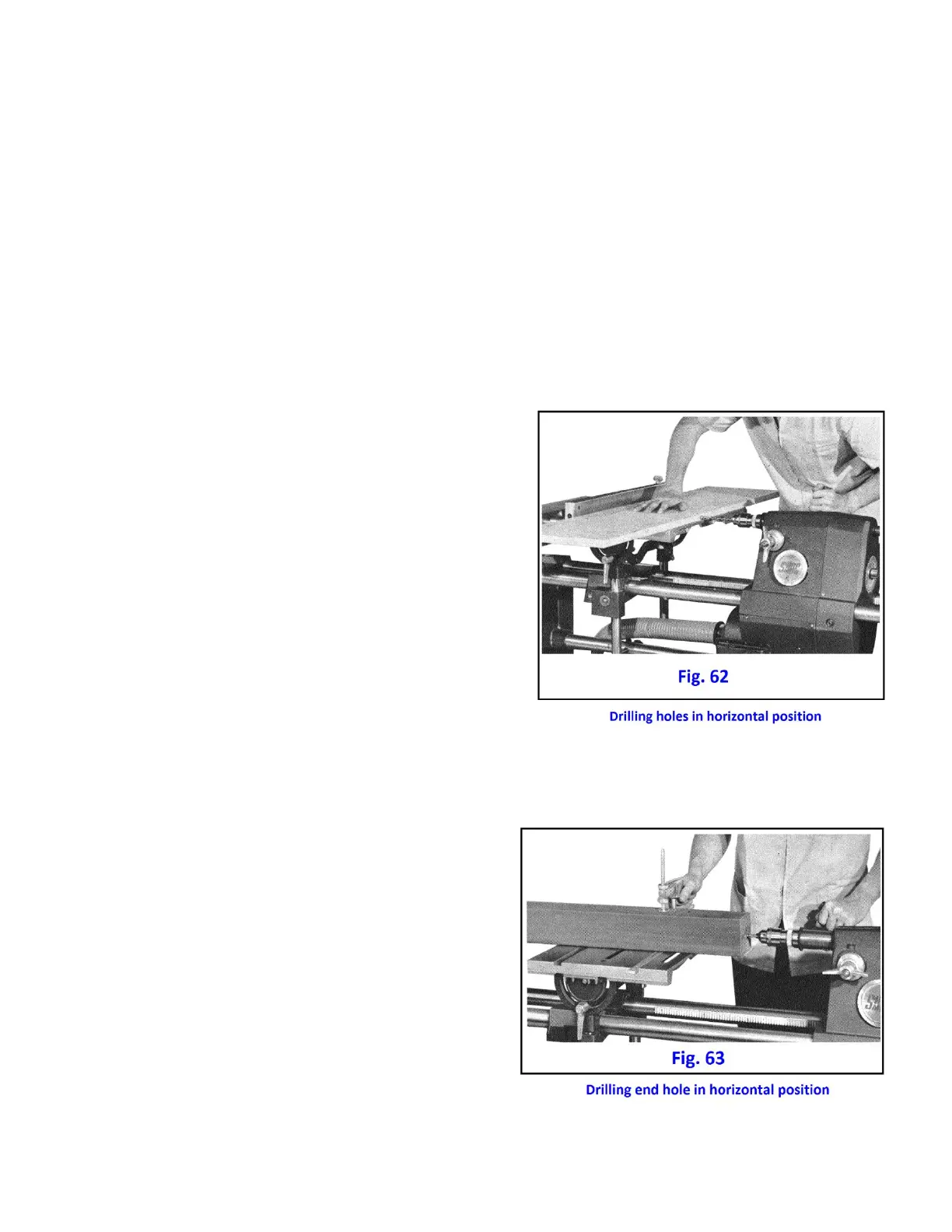

DRILLING FOR BUTT DOWEL JOINTS

Drilling edge holes for a butt dowel joint is easily

accomplished in wide or narrow boards with the setup

shown in Fig. 62. The rip fence is locked in place to act as a

backstop and as a guide to hold the work square to the

drill. The feed stop is locked to control hole depth. The

only dimension line needed on the board edges is distance

between holes. It is not necessary to center the holes

between edges if the operator makes certain to place the

same side of each board down on the table.

To mark the dimension lines for distance between holes,

hold the boards together and butt one end against the rip

fence. The miter gauge is an excellent tool for marking the

lines across the edges of the boards.

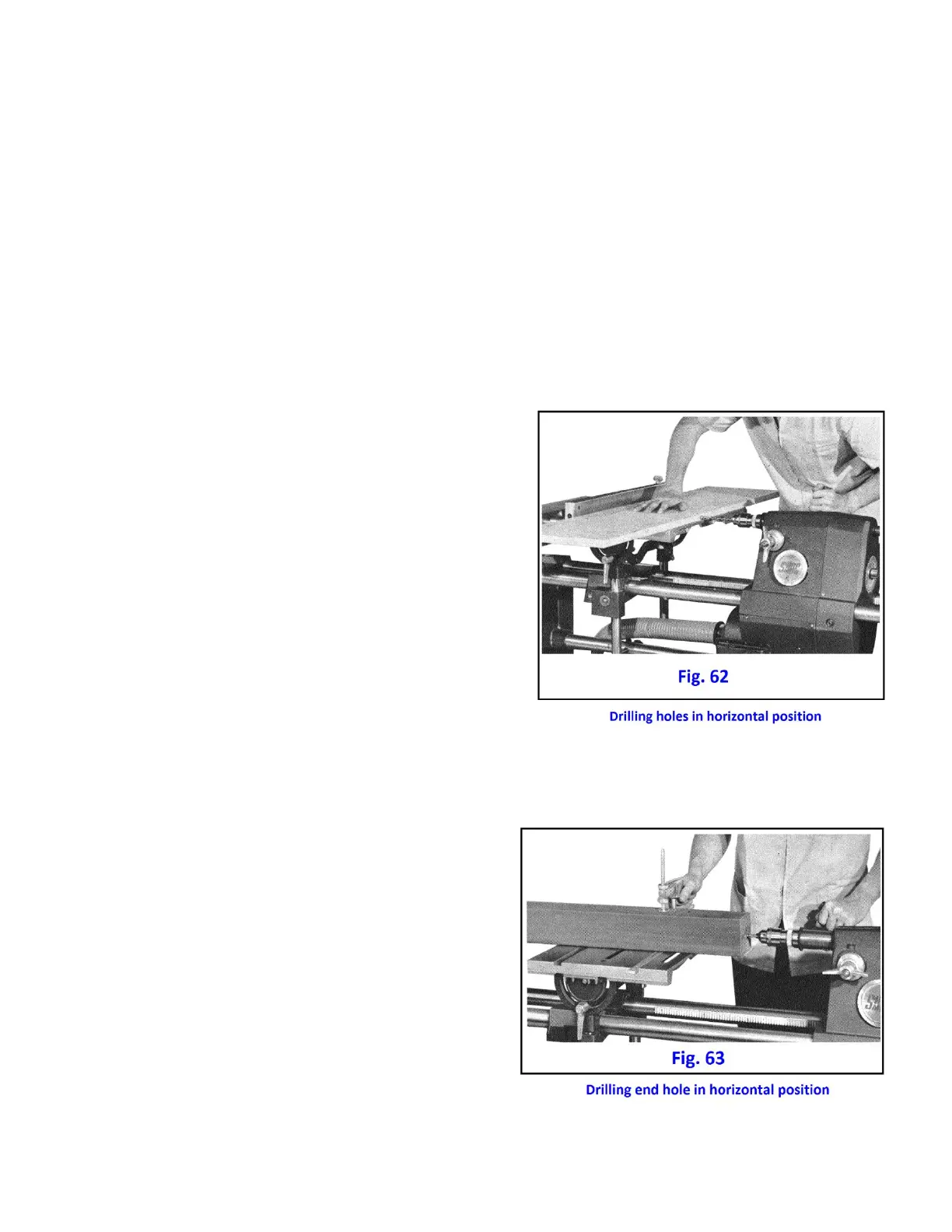

END DRILLING

Drilling end holes in long or short stock is done by locking

the miter gauge in place to act as a guide for the work

(Fig. 63). If you position the work accurately you can drill

through from each end of the piece with the assurance

that the holes will have a common centerline. The

extension table adds additional support for extra-long

work.

JIG DRILLING

Loading...

Loading...