Mark VII Restored Manual - V1.02 – Donated without cost to the world-wide Shopsmith Community - Everett L. Davis 2016 41

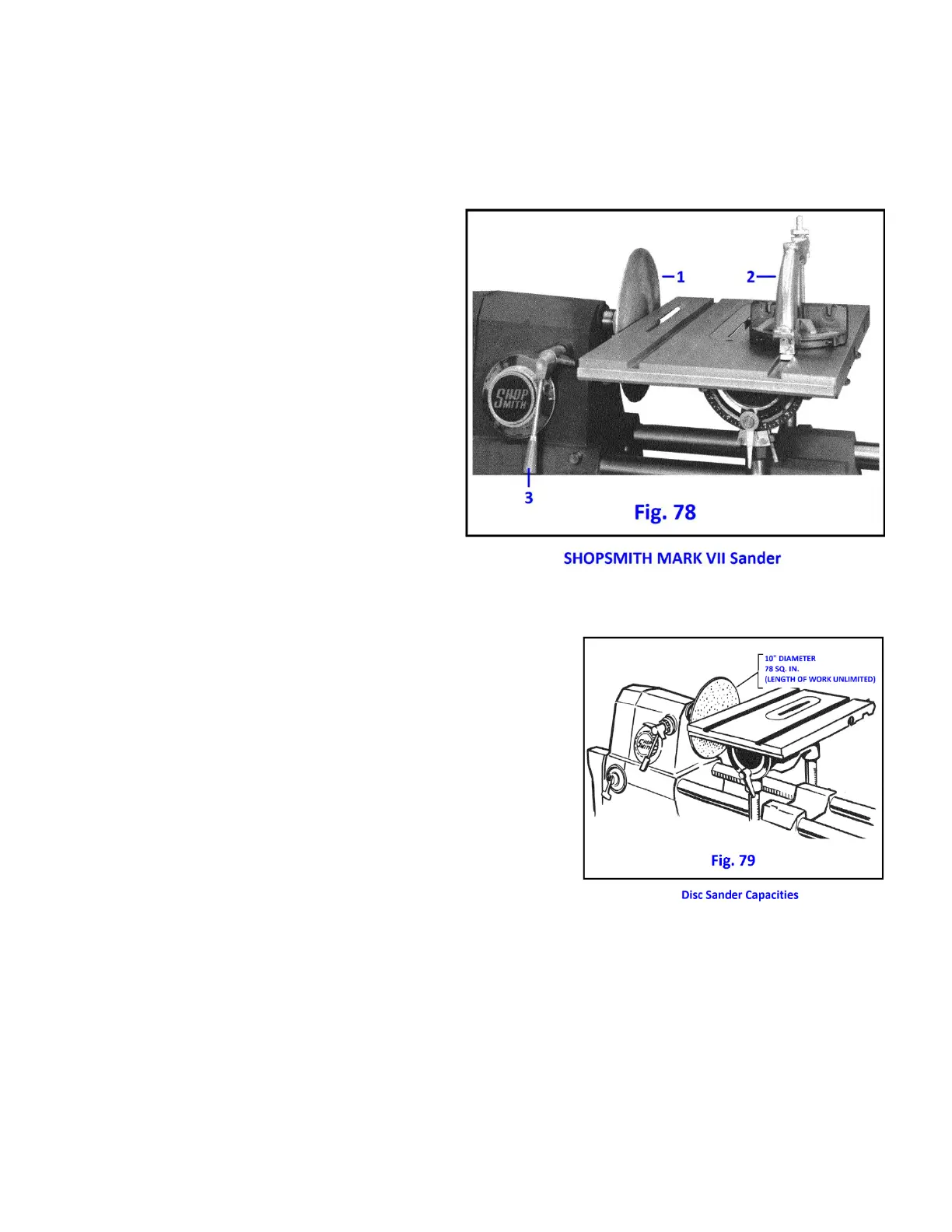

SHOPSMITH 10 INCH DISC SANDER

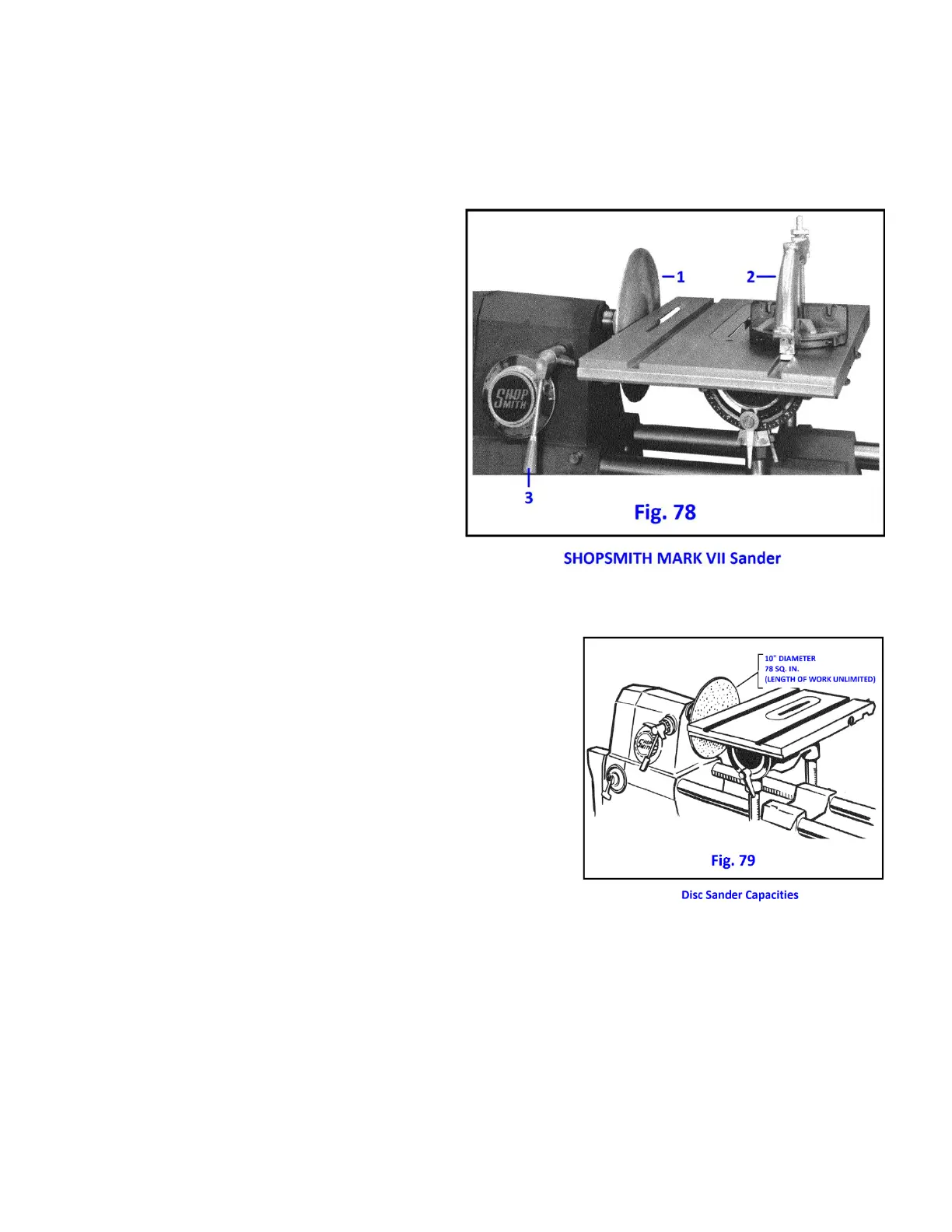

NOMENCLATURE

1. 10" Double Faced Sanding Disc - One side

conical, other side flat. Affords 78 square

inches of sanding area. Attached directly to

main or upper auxiliary spindle.

2. Miter Gauge - Used as stop or guide for

many sanding operations. Use with rip

fence to create jigs for duplicate sanding

and special operations.

3. Quill Feed Lever - Permits advancing disc

into work. Unparalleled accuracy for single

or duplicate parts because amount of work

sanded off can be mechanically controlled

with the feed stop.

HOW TO USE THE DISC SANDER

ATTACHING SAND PAPER

Liquid Adhesive (Item No. 505554) is applied to both the disc and

sandpaper sheet. Spread adhesive thinly and evenly and let dry

for 20 minutes or until it turns black. Press sandpaper onto disc.

This is contact bond cement - sheet cannot be moved after initial

contact so make sure it is correctly positioned.

Remove old sandpaper and adhesive completely before applying

a new sheet.

MOUNTING

The SHOPSMITH 10" disc can be used on either the main spindle

or the upper auxiliary spindle. On the main spindle it can be flat

face out or with coned face (hub side) out. Either way around it

may be used with the accessory lower saw guard in place for dust collection. On the auxiliary spindle the disc

can be mounted only with the flat face out.

Sanding is always done on the "down" side of the disc (Fig. 80). If it is ever necessary to use the "up" side of the

table, or if you are moving a long piece across the face of the disc, be sure to hold the work firmly down on the

table to prevent the disc from lifting it.

Loading...

Loading...