Mark VII Restored Manual - V1.02 – Donated without cost to the world-wide Shopsmith Community - Everett L. Davis 2016 39

ADJUSTING TOOL REST

The tool rest is mounted in the front table tube

hole. It is locked in the carriage by the wing nut

which locks the table height control.

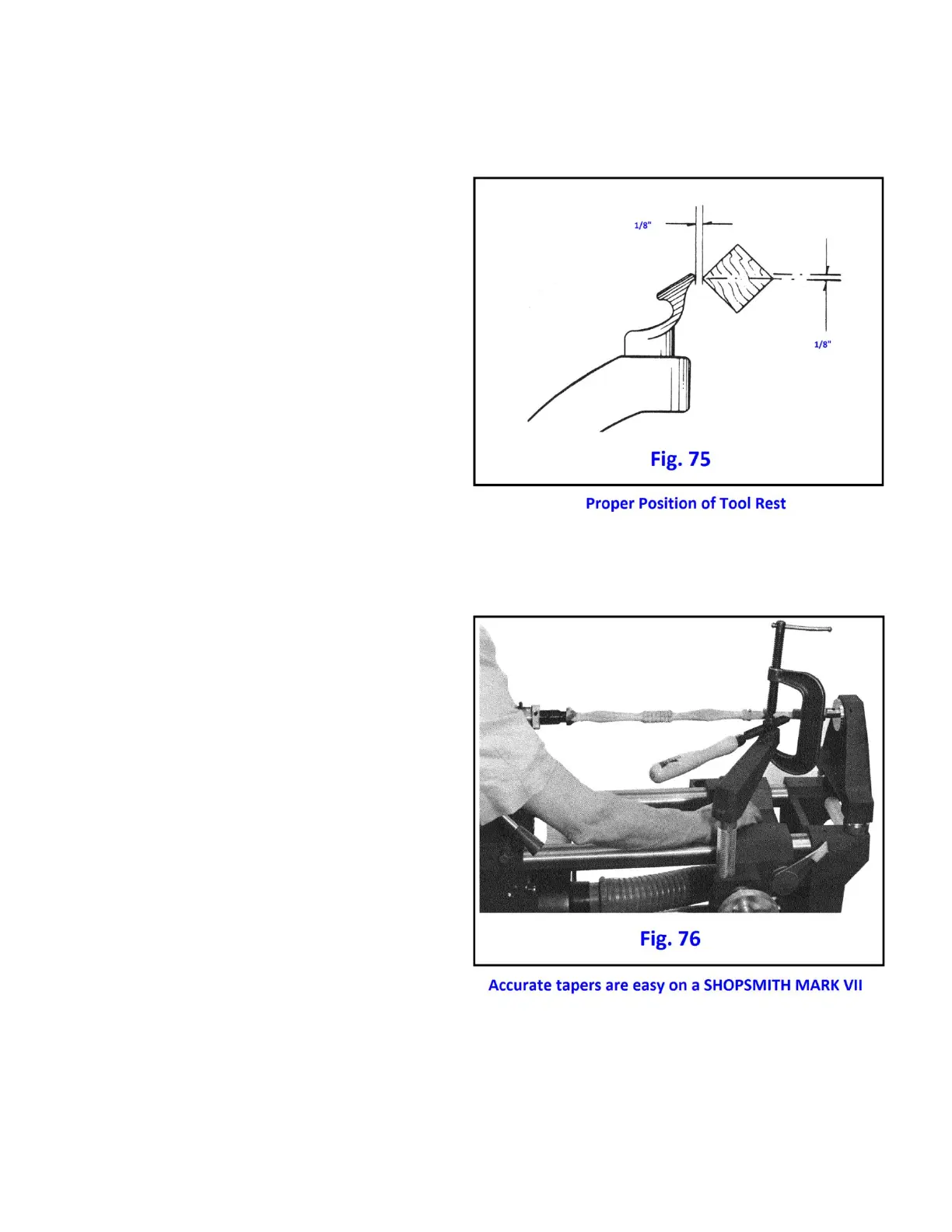

The tool rest is positioned as shown in Figure 75.

This is the ideal condition and should be

approximated as closely as possible at all times.

Naturally, because the size of the work

diminishes with successive cuts, it is impossible

for the tool rest to remain in one fixed position.

As turning proceeds, adjust the tool rest to give

maximum support to the chisels.

OFFSET TURNING

The SHOPSMITH MARK VII eccentric cup center

mount, combined with the controlled parallelism

of the tool rest makes turning tapers an almost

automatic job. The cup center mount is

calibrated in 16ths of an inch with a maximum

offset of 1/2". To use it, turn the stock to full

round, maximum diameter of the design. Turn

the cup center mount to the offset needed. Lock

in place and raise tailstock to bring points back

into correct alignment.

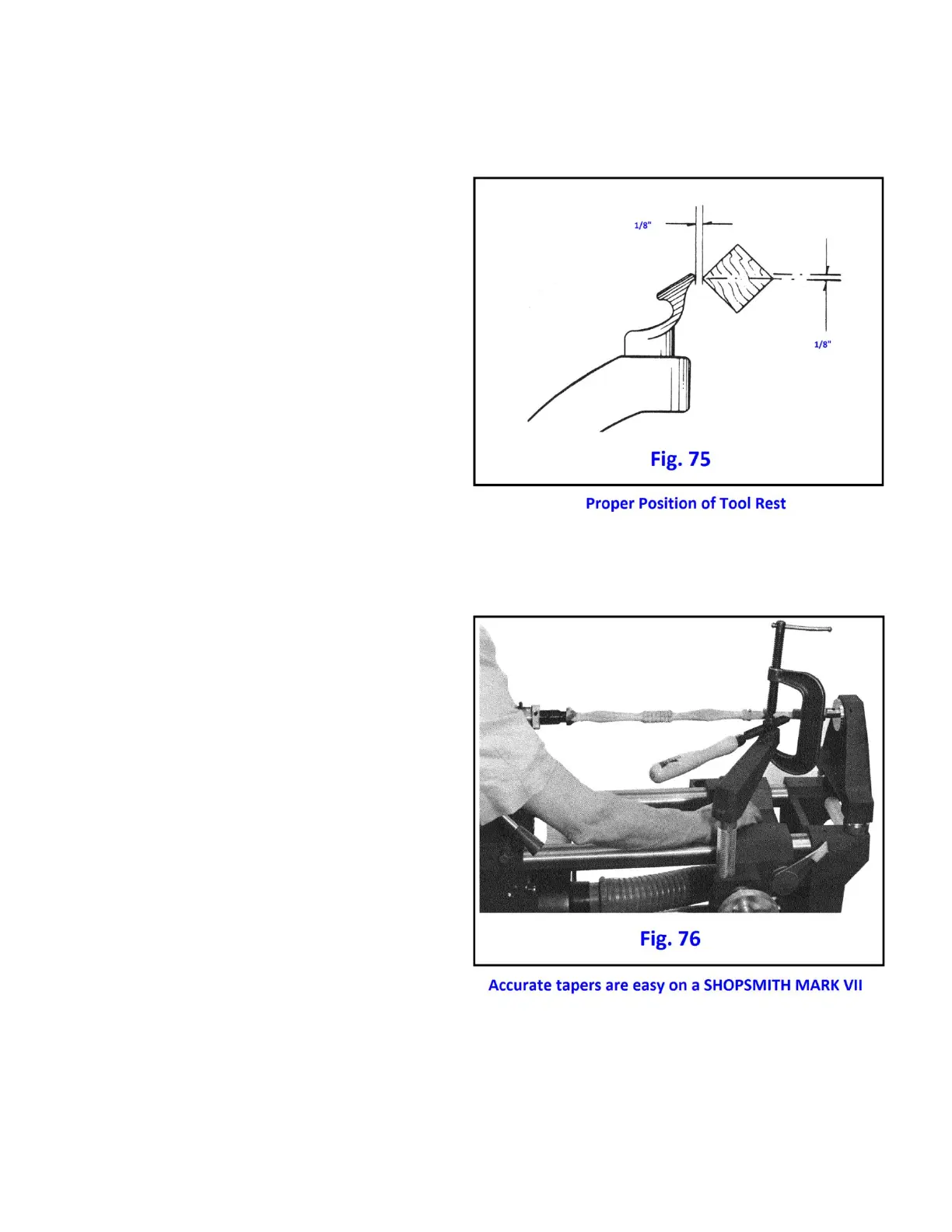

Clamp the turning tool (the gouge will do a good

job) to the top of the tool rest arm (Fig. 76) and

situate it for a light cut. Turn on the machine and

advance the tool slowly by sliding the carriage.

Move the carriage slowly and make successive

passes until the taper is complete. Smooth with

sandpaper as you would any other turning.

Loading...

Loading...