Mark VII Restored Manual - V1.02 – Donated without cost to the world-wide Shopsmith Community - Everett L. Davis 2016 34

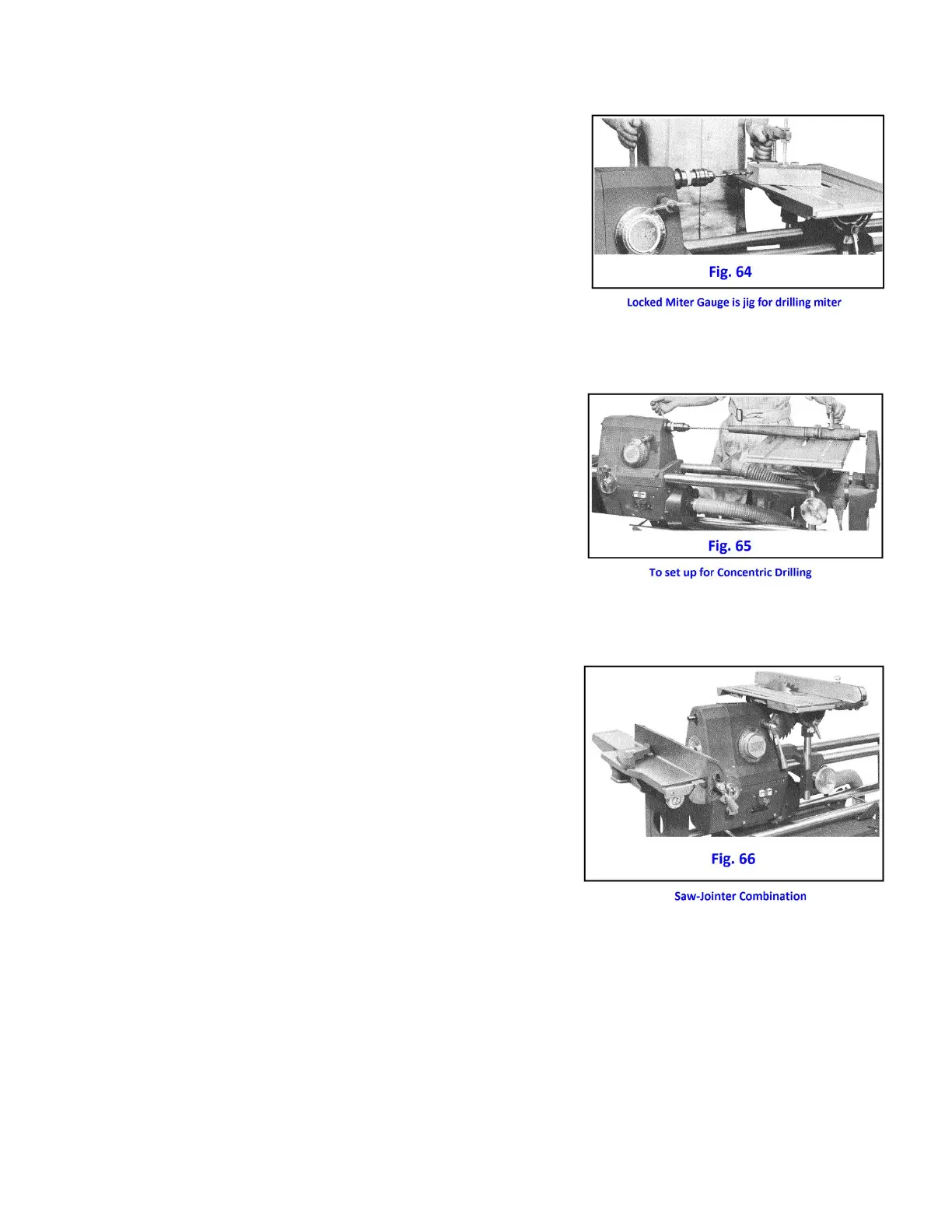

Figure 64 shows how easy it is to set up for drilling dowel holes in

mitered pieces. Lock the miter gauge in place to act as a stop and

guide for the work and clamp the work to the table before drilling.

It is a good idea to set up so that aligning the front of the work

with the front edge of the table positions it to maintain uniform

hole depth.

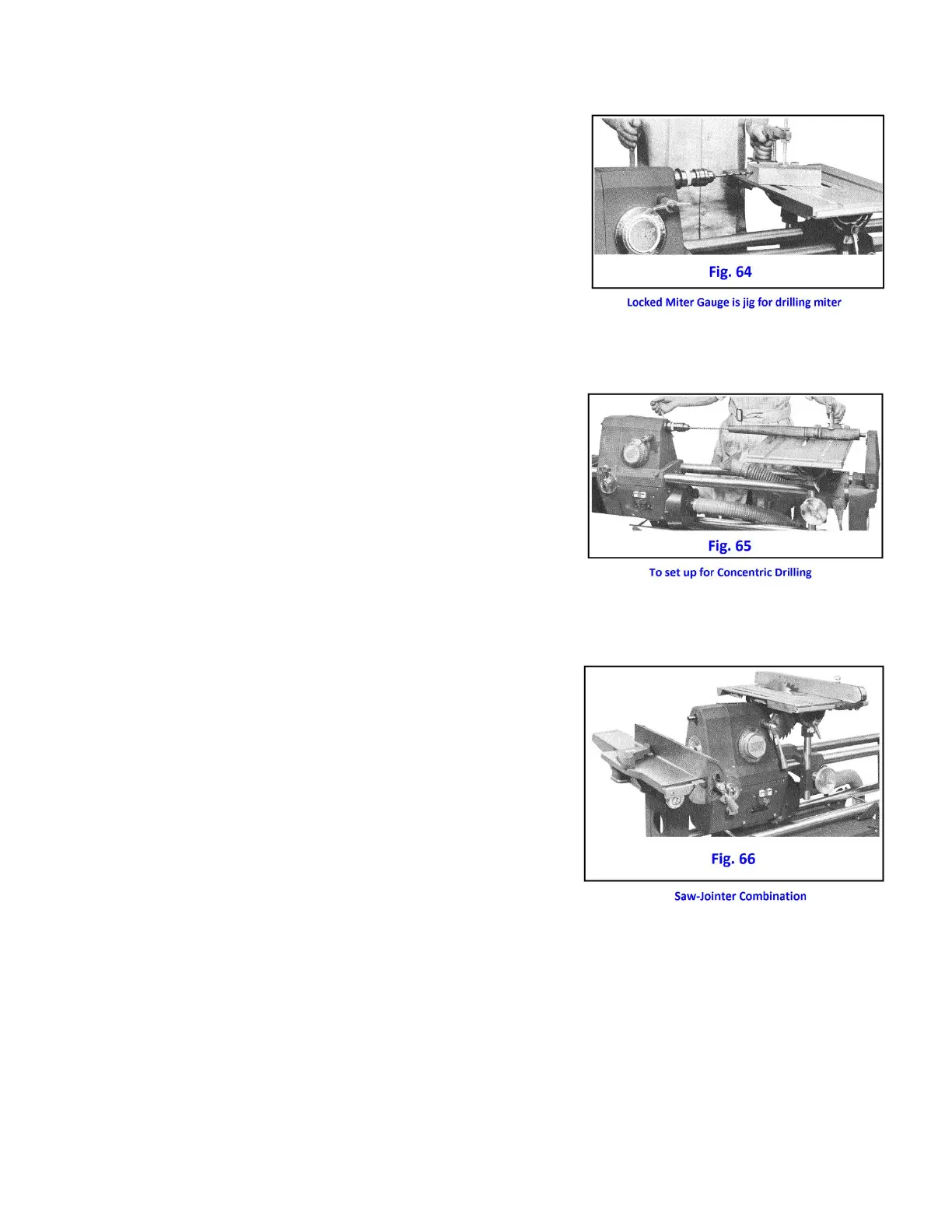

CONCENTRIC DRILLING

Concentric holes needed in lamp bases and similar projects are

easily drilled as shown in Figure 65.

The tailstock and cup center (see section on THE LATHE) are

mounted in the right hand power mount holes. One end of the

work is positioned on the cup center and the other end centered

with the drill bit. Raise the table to support the work and lock the

miter gauge in place to act as a stop and guide.

OTHER OPERATIONS WITH HORIZONTAL SPINDLE

Auxiliary operations usually performed on a "Polishing Head",

with its own separate stand and motor and limited capacity, can

be done better on SHOPSMITH. With MARK VII you have a

double-end spindle plus quill action, plus variable speed for any

tool or operation.

The double-end spindle makes possible dual mounting of

complementary tools. Not only the traditional saw-jointer setup

(Fig. 66) but other worthwhile combinations.

When mounting accessories on the MARK VII spindles be sure to use arbors with a keyway and tongued washer

- Item Nos. 505506 (5/8" arbor) and 505505 (1/2" arbor). These are designed to prevent the arbor nut from

loosening regardless of direction of rotation and may be used on front or rear spindles.

NEVER USE A CONVENTIONAL ARBOR HAVING A RIGHT HAND THREAD unless rotation of the spindle for the

particular application is counterclockwise when viewed from the shaft end.

Loading...

Loading...