Mark VII Restored Manual - V1.02 – Donated without cost to the world-wide Shopsmith Community - Everett L. Davis 2016 43

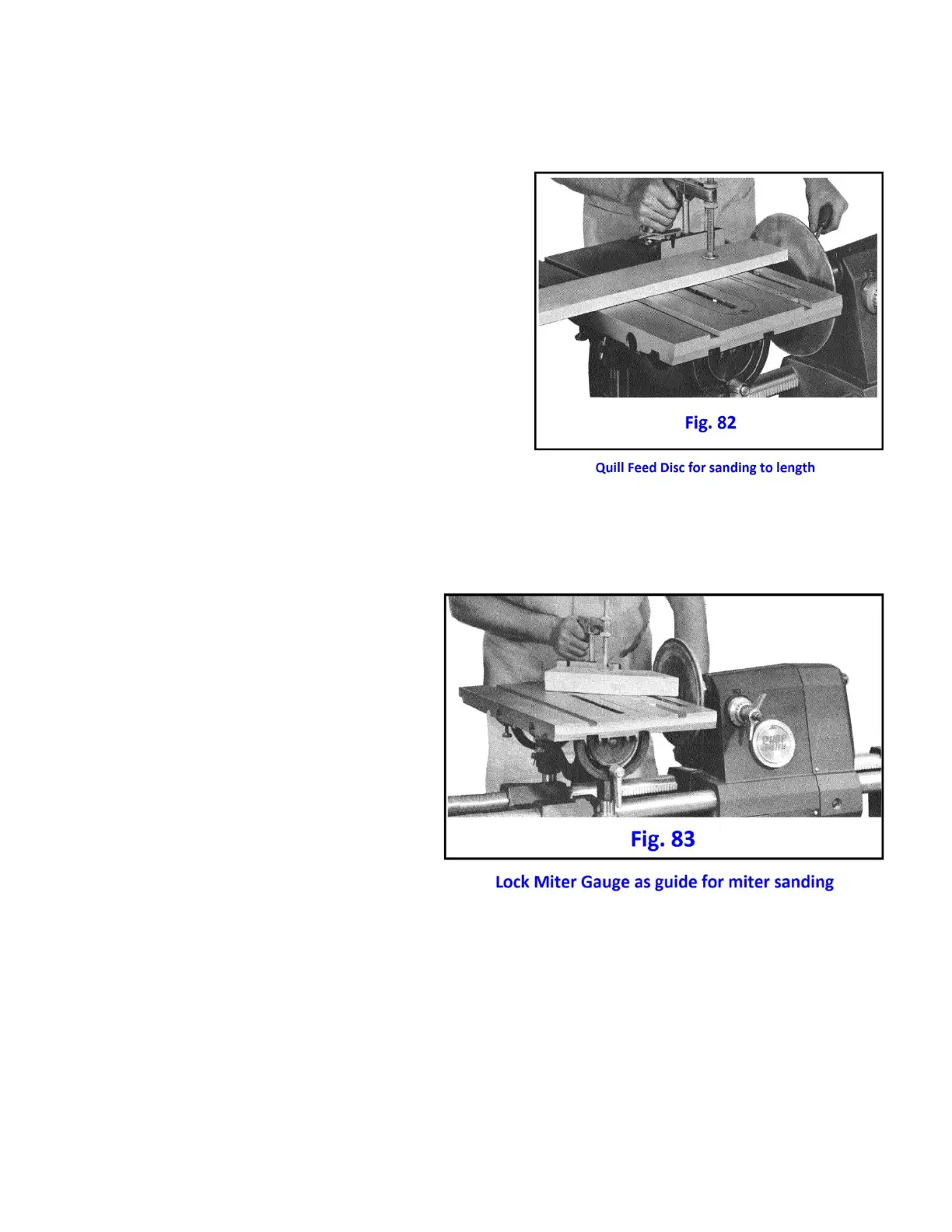

SANDING TO LENGTH

Hold the work with miter gauge safety grip and advance

quill for fine feed (Fig. 82). Duplicate pieces are quickly

and easily sanded to exact length by the following

method: Lock the table about 1/2" away from the disc.

Set the rip fence on the table or extension table,

depending on length of work. Lock miter gauge in place to

act as a guide for the work. Place one work piece on the

table and sand to the exact length required by feeding the

disc into it.

Turn off machine and extend disc to butt against sanded

piece. Set depth control dial and lock the feed stop. Then

sand each piece by placing in jig formed by miter gauge

and rip fence and feeding disc forward.

FEED SLOWLY - NEVER FORCE THE DISC INTO THE WORK.

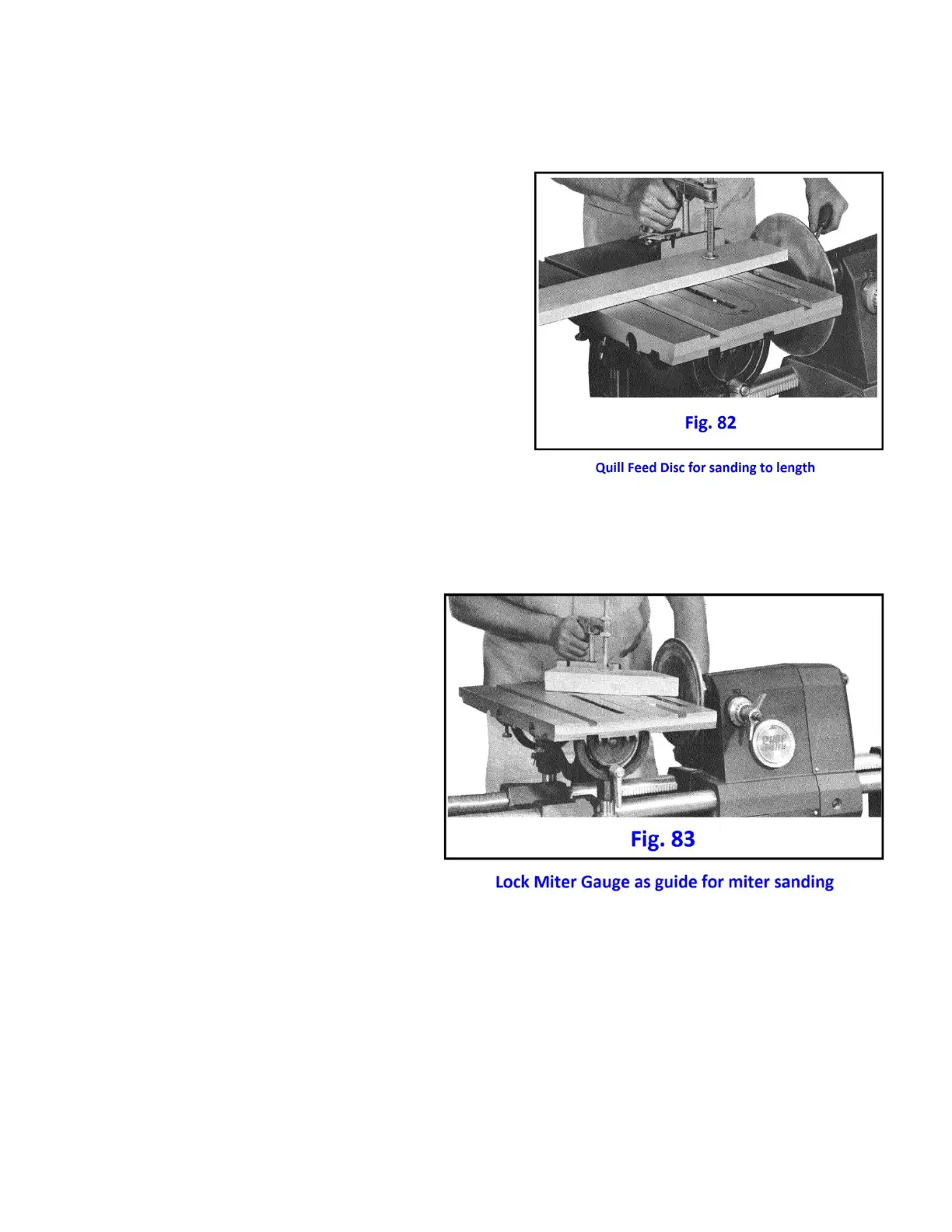

MITER SANDING

The best way to get perfect miters is to saw

the pieces about 1/16" oversize and sand

them to exact length (Fig. 83). Lock the

miter gauge in place after it has been set to

the angle needed. Place and hold the work

firmly against the miter gauge and feed the

disc forward.

ANGULAR SANDING

For bevels and cross miters tilt the table to

the angle needed and sand as you would any

other piece. Always tilt the table to form an

open angle with the disc. If you tilt the other

way there is the possibility, especially with

thin pieces, that the work will grab between

the edge of the table and the disc.

To sand compound angles set the miter gauge and table to the same angles used to cut the pieces on the saw.

Loading...

Loading...