8 Troubleshooting

8.1 Possible errors during commissioning

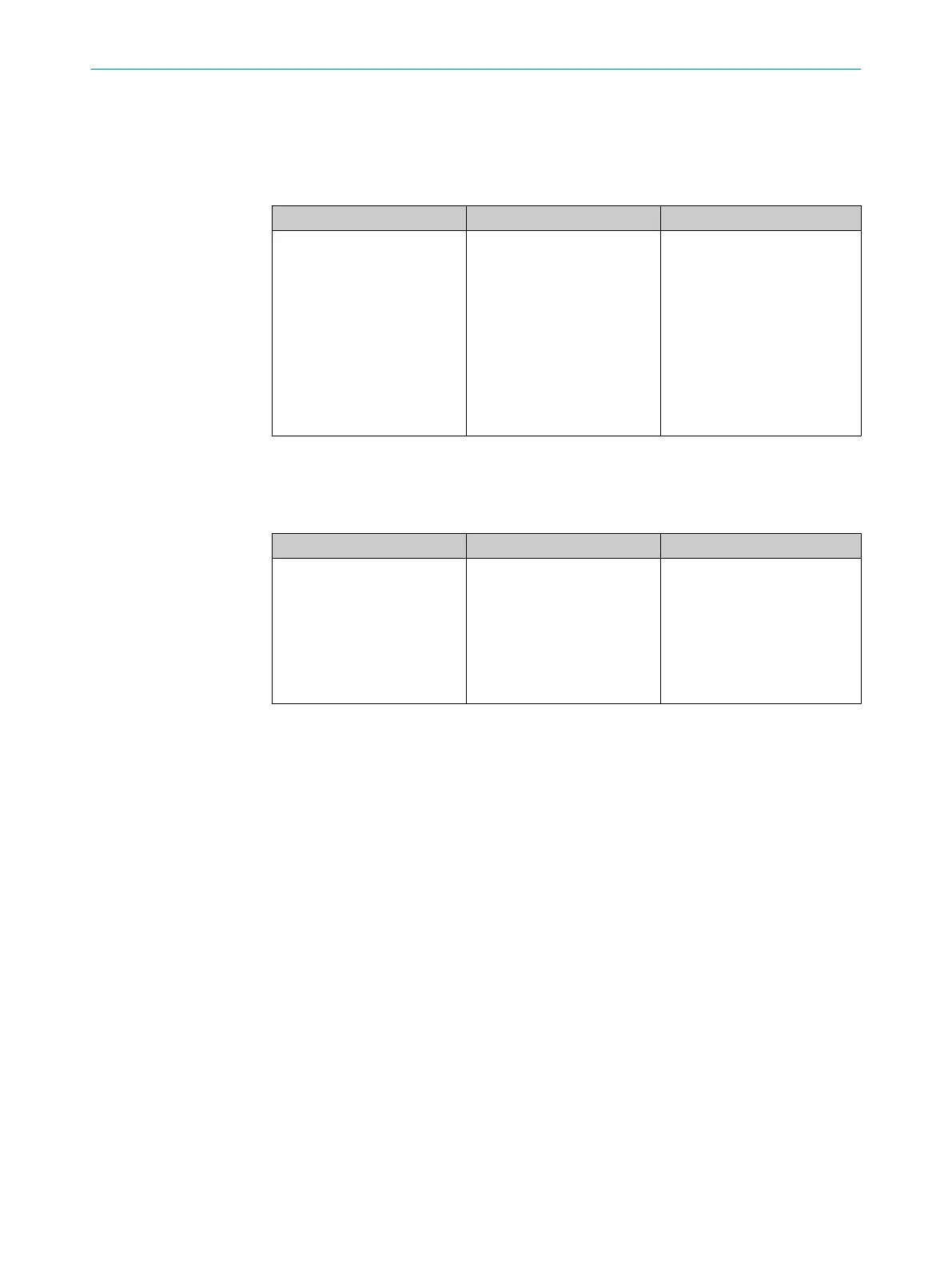

Table 8: Troubleshooting during commissioning

Display, error situation Cause Measure

After the teach process

•

“Err1” is displayed

•

“Err2” is displayed

•

“Err3” is displayed

Programmed contrast or con‐

trast difference is not suffi‐

cient for stable contrast detec‐

tion.

•

“Err1”: Receive value is too

low

•

“Err2”: Receive value is

saturated

•

“Err3”: Difference between

two receive values is too

small

•

Readjust fibers

•

Clean fibers

•

Check the application con‐

ditions

•

Restart teach process

•

Increase contrast difference

8.2 Possible errors during operation

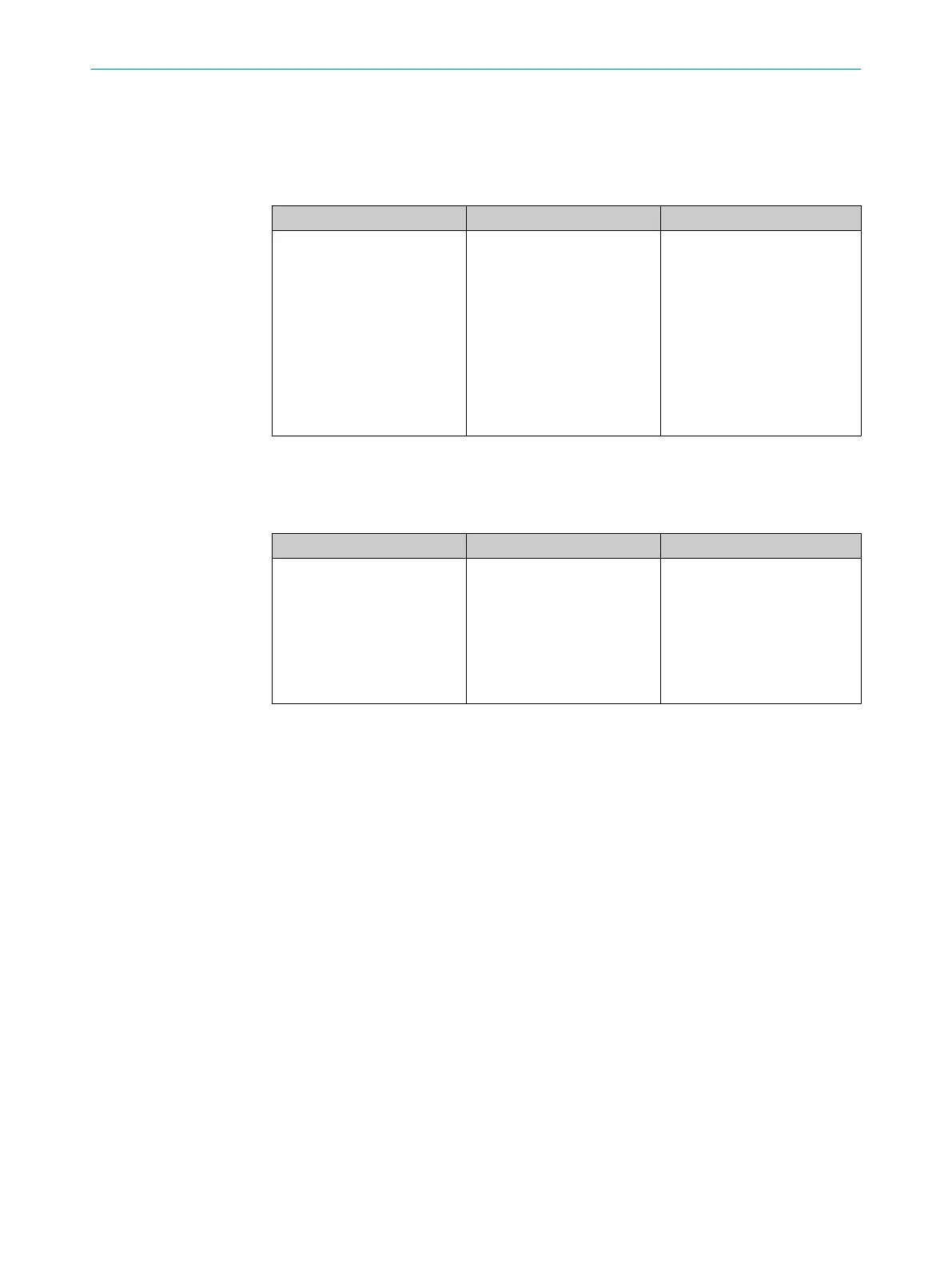

Table 9: Troubleshooting during operation

Fault pattern Cause Measure

No switching output any more

•

Distance or angle to mater‐

ial not consistent

•

Light emission (optics) is

dirty

•

Manual switching thresh‐

old set incorrectly

•

Fibers have detached from

the amplifier

•

Clean fibers

•

Readjust fibers

•

Check parameter settings

•

Perform teach process

again

•

Check fiber mounting

8 TROUBLESHOOTING

40

O P E R A T I N G I N S T R U C T I O N S | KTL180 8023304.11XV/2018-11-29 | SICK

Subject to change without notice

Loading...

Loading...