RAY26P-xxxxx5

RAY26P-xxxxx9

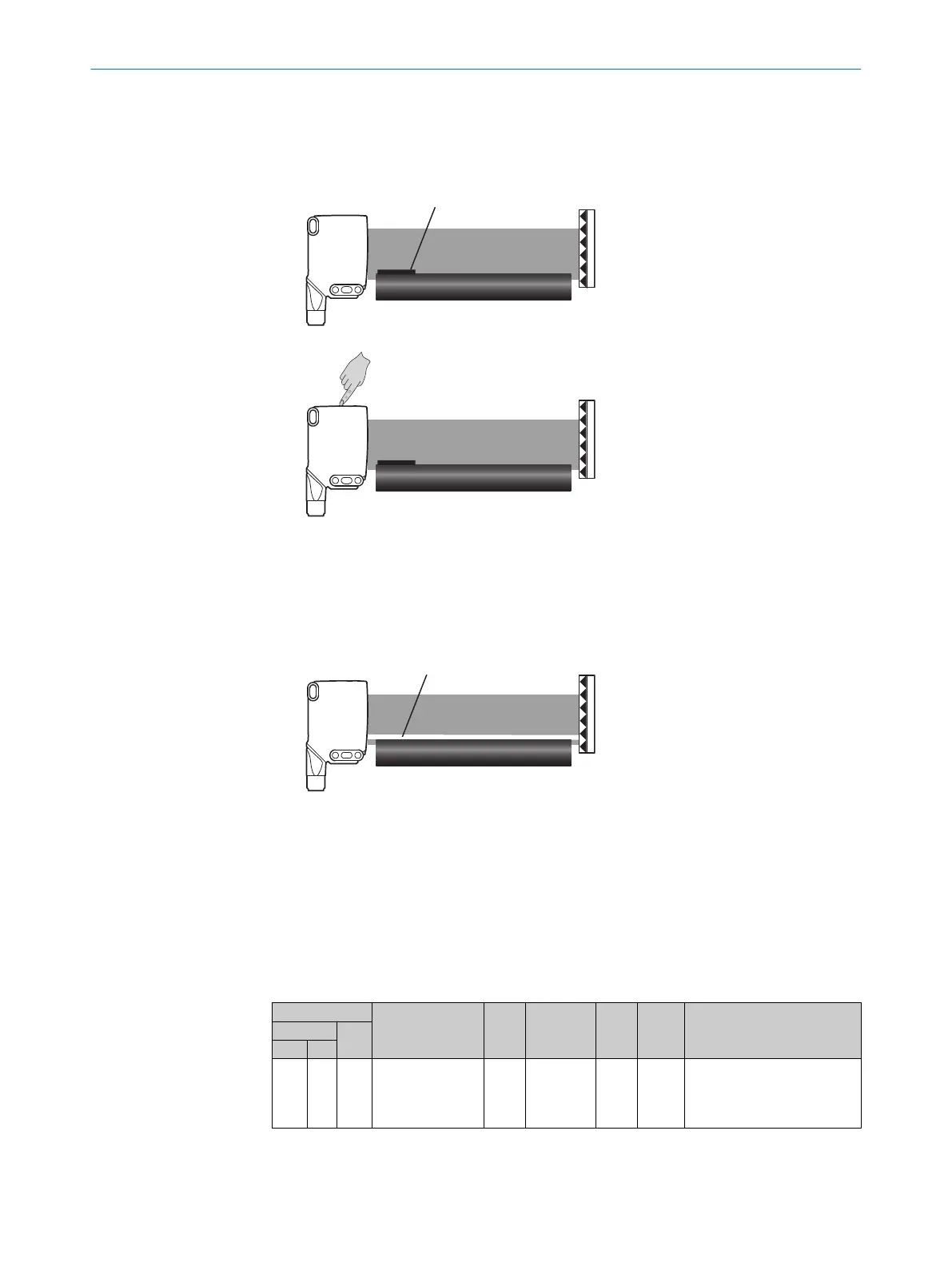

1. Place an object A with the corresponding height to be blanked (e.g. 3 mm) in the

light band in front of the RAY26.

2. Teach RAY26 and it is ready for use.

3. Remove the object from the light band.

This area (B = object height A) is now blanked for detection.

If the conveyor belt moves a little bit up, it is not detected.

An object must now be e.g. approx. 8 mm high so that it can be detected by

RAY26P-xxxxx5 (MDO: 5 mm). If the RAY26 is re-teached without object A into the

light band, then the blanked area is no longer present and is available for detec‐

tion again.

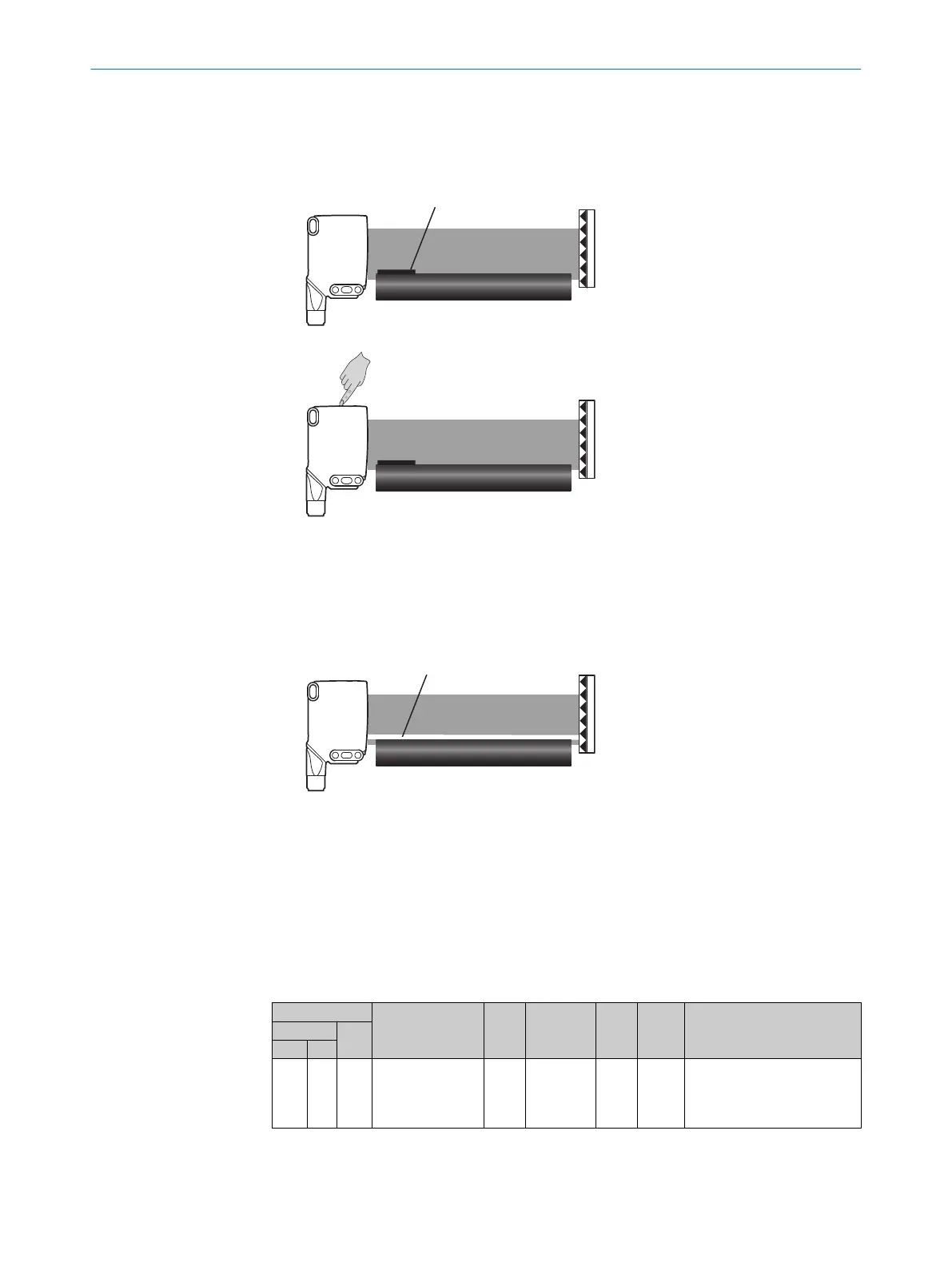

Conveyor blanking via IO-Link

RAY26P-xxxxx3

The conveyor blanking allows a stepwise inactivation of the detection area (A = approx.

1 mm for each level) just above the conveyor belt. Thereby influences of the conveyor

belt (which causes false signals of the sensor) can be suppressed. The setting of the

conveyor blanking can be done via IO-Link with the index 238.

After setting the sensor has to be taught again (index 2, value 65).

Table 7: Index 238

ISDU

Name

Data

type

Length Access

Default

value

Value/RangeIndex

Sub-

Index

DEC HEX

238

0xE

E

- Conveyor blanking Uint 8 Bit rw 0

0 = Deactivated

1 = Level 1

2 = Level 2

3 = Level 3

4 = Level 4

7 COMMISSIONING

14

8022178.18JF 02.07.2020 | SICK

Subject to change without notice

Loading...

Loading...