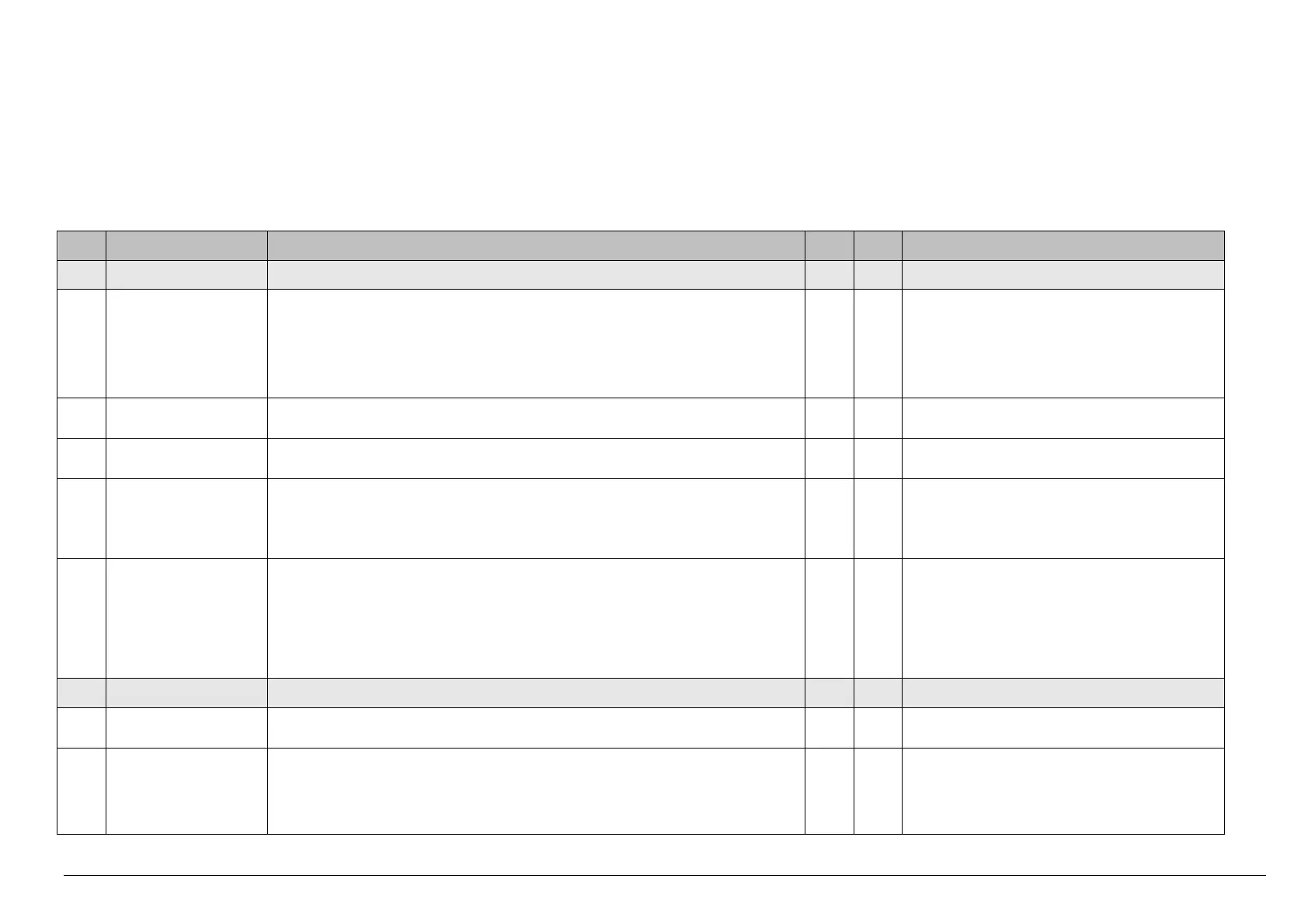

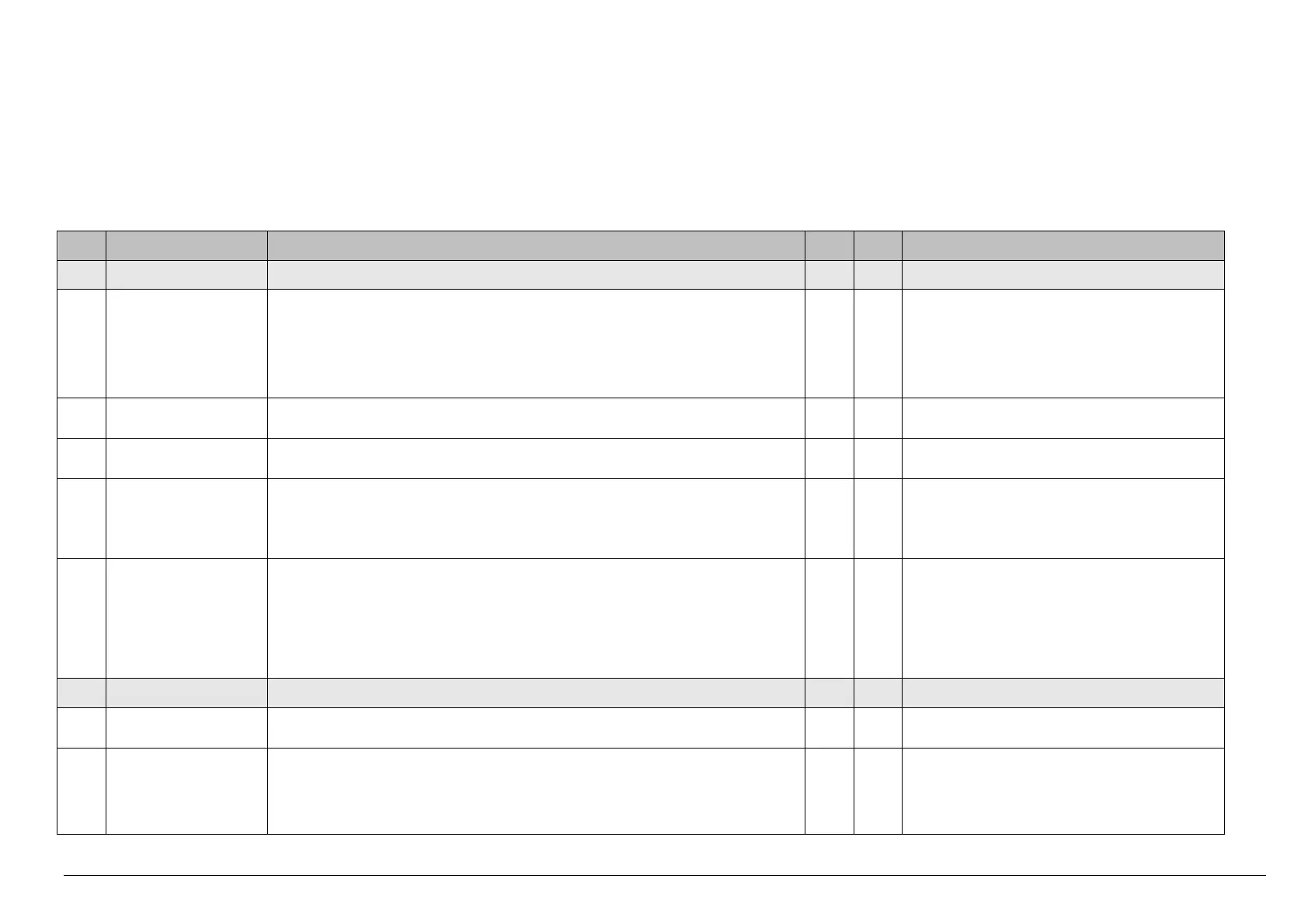

8PQ9801-8AA61 B1 en

ALPHA 3200 Eco

Maintenance Check List

General inspection and servicing of the low-voltage switchboard

For the installed equipment, the manufacturer’s operating instructions take precedence and must be complied with.

Item

No.

Work to be performed Notes / Criteria Yes No Remarks / Result

1 External visual

inspection

1.1 Ambient conditions

- Switchboard is configured for the existing ambient conditions

- Maintenance is performed according to the operating conditions (maintenance intervals)

- Signs of loading with sulfurous gases (formation of pollution layers on silver-plated

components and copper bars)

- Impermissible high temperature (>35°C), excessive air humidity or dust loading in the

switch room

1.2 Efficiency of the

ventilation

- Ventilation openings are not covered or blocked

- Unobstructed entry and exit of air to and from the sections possible

1.3 Tools and accessories

- Complete

- In a perfect working order

1.4 Documentation

- Circuit diagrams of switchboard and functional units available

- Necessary operating instructions of the switchboard available

- Necessary operating instructions of devices available

- Documentation up to date

1.5 Condition of enclosure

- Damage or corrosion present

- All doors, side and top covers present

- Doors closed, all locks engaged

- Sealing material on doors in working order

- Existing ventilation openings in door, top plate and rear wall are free of dirt and dust

- Clean or replace existing filter mats

2 Internal visual

inspection

2.1 Covers, separations

- Complete

- Protection against electric shock is ensured

2.2 Pollution

- Dust deposits and pollution inside the switchboard

- Impairment of mechanical functions

- Effectiveness of the device ventilation

- Impairment of the clearance and creepage distances by pollution or foreign bodies

Loading...

Loading...