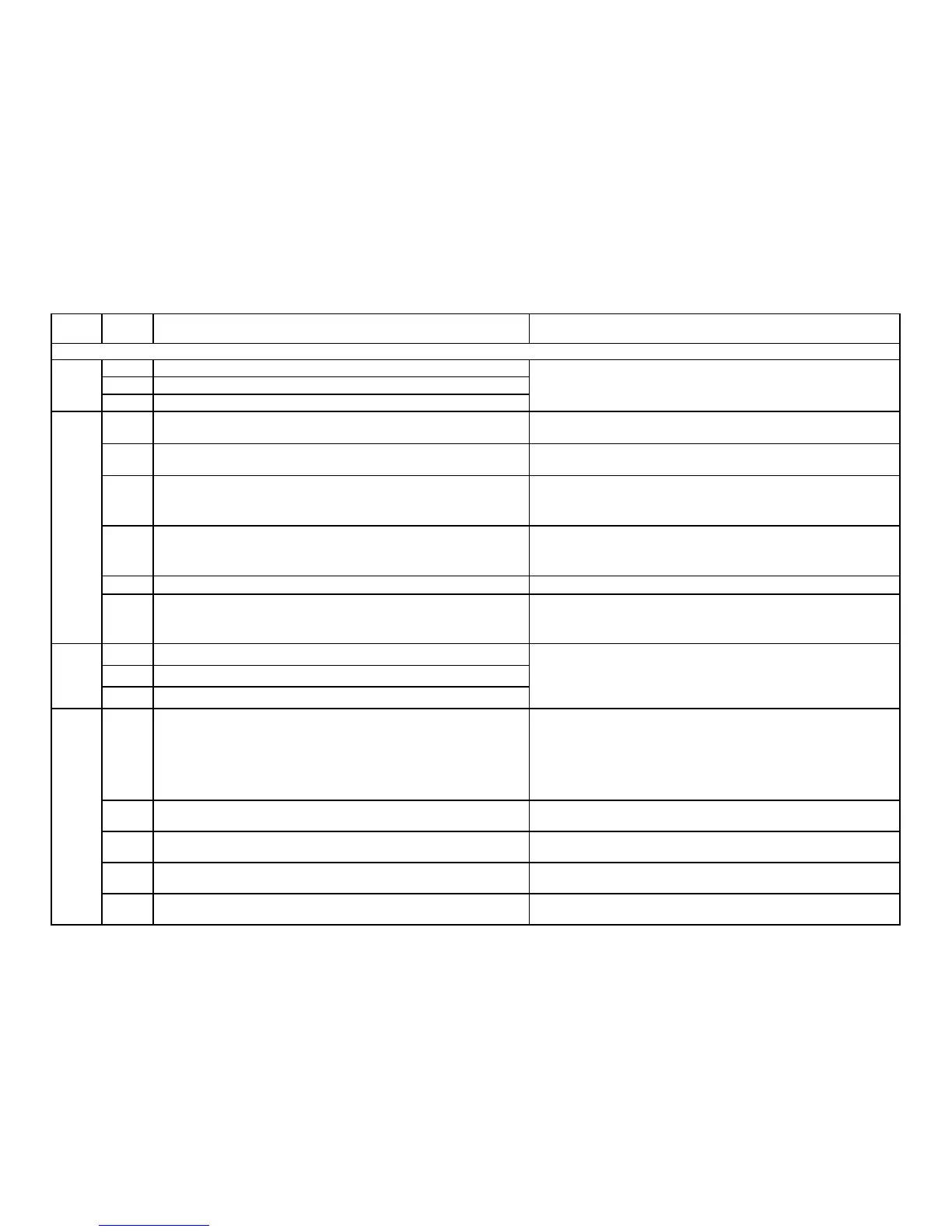

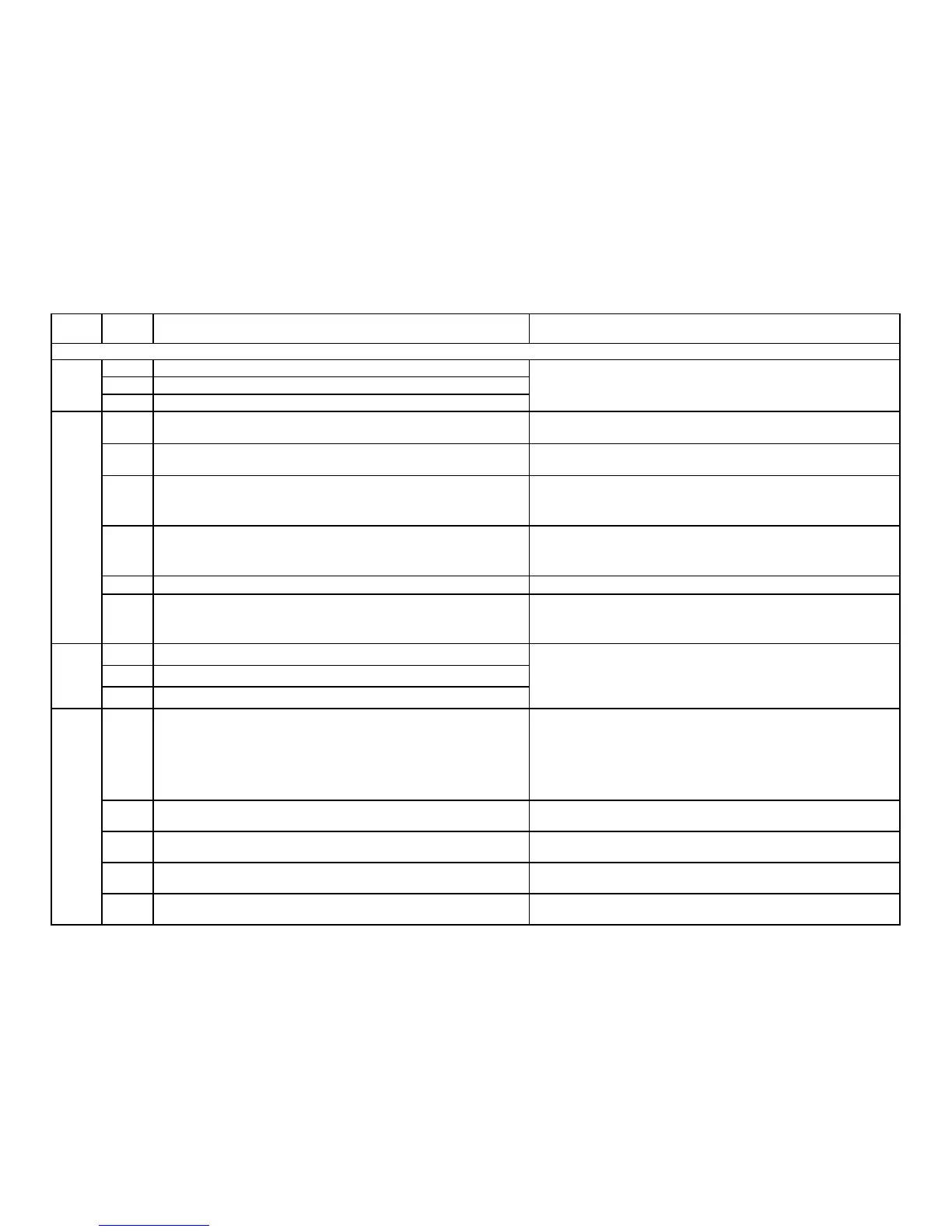

Meaning for the LMV3 System Corrective Action

Note: Diagnostic codes are additive. If a diagnostic code appears that is not on this list, it is a combination of multiple diagnostic codes.

Any # Timeout building automation interface

1 Modbus timeout

2 Reserved

Any # TUV test

A fault occurred during the TUV test. See diagnostic codes for more

information.

1 (-1) Invalid phase

The TUV test can only be started in phase 60 (operation). Reset the fault.

When the LMV3 reaches phase 60, attempt to start the TUV test again.

2 (-2) TUV test default output too low

The TUV test default output (parameter 133/134) cannot be set lower than

the lower load limit (parameter 545/565). Either increase the TUV test

default output or decrease the lower load limit, then reset the fault.

3 (-3) TUV test default output too high

The TUV test default output (parameter 133/134) cannot be set higher

than the upper load limit (parameter 546/566). Either decrease the TUV

test default output or increase the upper load limit, then reset the fault.

4 (-4) Manual interruption No fault: The TUV test was aborted manually by the user.

5 (-5) TUV test timeout

There was no loss of flame after shutdown of the fuel valves. Check for

extraneous light or a faulty flame scanner, then reset the fault and start

the TUV test again.

Any # Trim function: Invalid analog value

1 Start prevention

2 Warning (trim function temporarily disabled)

Any # Trim function: Invalid curve setting of VSD / PWM blower

The following equations set the limits on the curve settings for the VSD /

PWM blower.

Fuel 0: Parameter 669:00 + parameter 547 ≤ curve point ≤ parameter

669:01 - parameter 548

Fuel 1: Parameter 669:00 + parameter 567 ≤ curve point ≤ parameter

1-9 Minimum value VSD curve invalid

A VSD curve point is below the permissible minimum value (diagnostic

code = point number, example: 1 = point P1)

21-29 Maximum value VSD curve invalid

A VSD curve point is above the permissible maximum value (diagnostic

code = point number, example: 21 = point P1)

41-49 Fuel 1: Minimum value VSD curve invalid

Fuel 1: A VSD curve point is below the permissible minimum value

(diagnostic code = point number, example: 41 = point P1)

61-69 Fuel 1: Maximum value VSD curve invalid

Fuel 1: A VSD curve point is above the permissible maximum value

(diagnostic code = point number, example: 61 = point P1)

155

146

150

154

Modbus communication has been interrupted for longer than the setting

of parameter 142. Re-establish communication, then reset the fault.

An invalid 4-20 mA signal was detected on input X64. Check the wiring to

terminal X64. Check the value of parameter 916. A value under -16%

indicates <4 mA is being detected, while a value over 26% indicates >20

mA is being detected.

Section 6 Page 20 SCC Inc.

Loading...

Loading...