International English 2. INSTALLATION

18 MICROMASTER 420 Operating Instructions

6SE6400-5AA00-0BP0

!

Warnings

♦ Work on the device/system by unqualified personnel or failure to comply with

warnings can result in severe personal injury or serious damage to material. Only

suitably qualified personnel trained in the setup, installation, commissioning and

operation of the product should carry out work on the device/system.

♦ Only permanently-wired input power connections are allowed. This equipment must

be grounded (IEC 536 Class 1, NEC and other applicable standards).

♦ If a Residual Current-operated protective Device (RCD) is to be used, it must be an

RCD type B.

♦ Machines with a three-phase power supply, fitted with EMC filters, must not be

connected to a supply via an ELCB (Earth Leakage Circuit-Breaker EN50178

Section 5.2.11.1).

♦ The following terminals can carry dangerous voltages even if the inverter is

inoperative:

- the power supply terminals L/L1, N/L2, L3.

- the motor terminals U, V, W, DC+, DC-

♦ Always wait 5 minutes to allow the unit to discharge after switching off before

carrying out any installation work.

♦ This equipment must not be used as an ‘emergency stop mechanism’ (see EN

60204, 9.2.5.4)

♦ The minimum size of the earth bonding conductor must be equal to or greater than

the cross-section of the power supply cables.

!

Caution

The connection of power, motor and control cables to the inverter must be carried out

as shown in Figure 2-4 on page 25, to prevent inductive and capacitive interference

from affecting the correct functioning of the inverter.

2.1 General

Installation after a Period of Storage

Following a prolonged period of storage, you must reform the capacitors in the inverter.

The requirements are listed below.

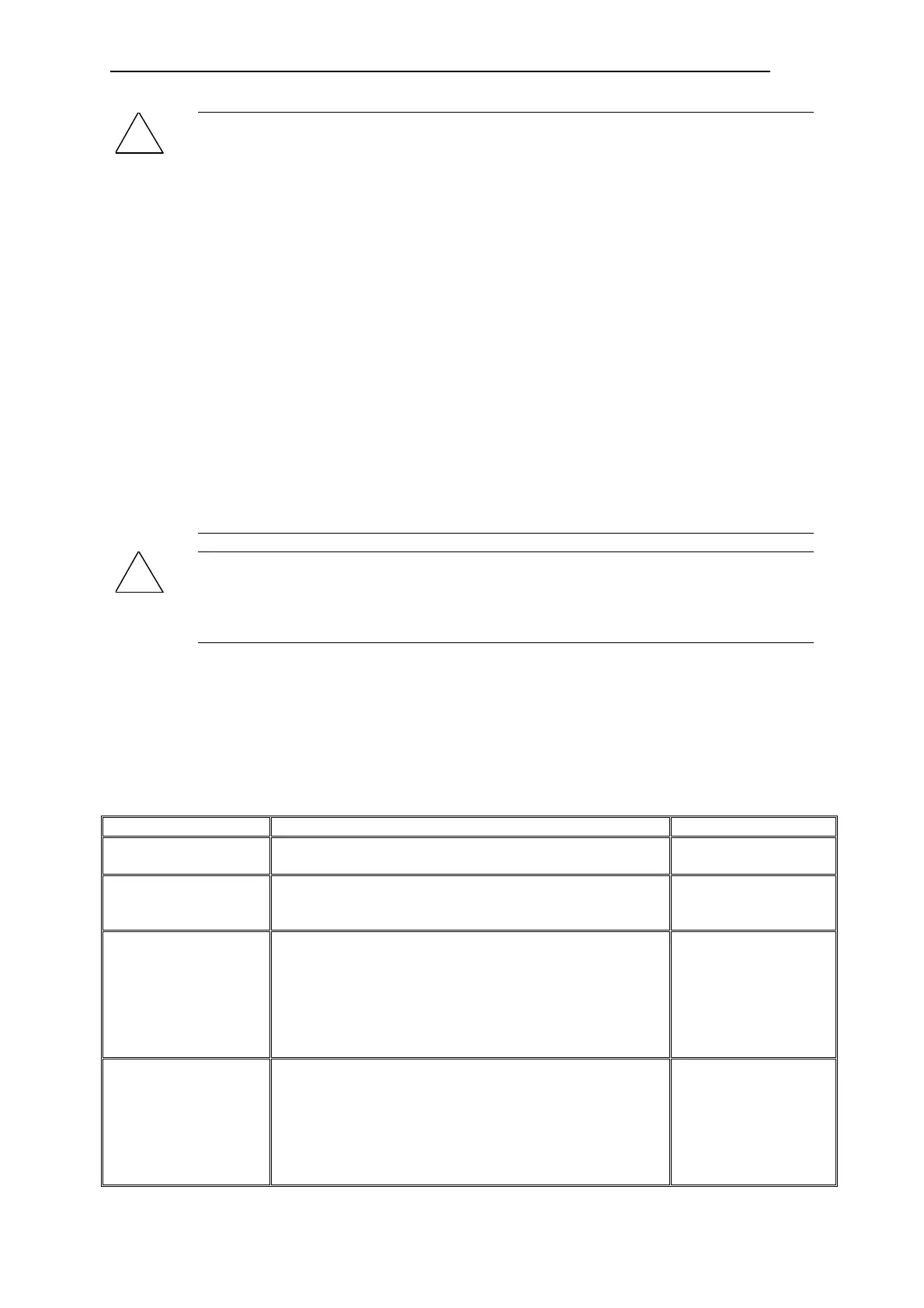

Period of Storage Required Action Preparation Time

1 year or less No reforming required No preparation

1 to 2 years Apply power to the inverter for one hour before issuing

the run command

1 hour

2 to 3 years Use a variable AC supply

Apply 25% of input voltage for 30 minutes

Increase volts to 50% for a further 30 minutes

Increase volts to 75% for a further 30 minutes

Increase volts to 100% for a further 30 minutes

Inverter ready for run signal

2 hours

3 years and over Use a variable AC supply

Apply 25% of input voltage for 2 hours

Increase volts to 50% for a further 2 hours

Increase volts to 75% for a further 2 hours

Increase volts to 100% for a further 2 hours

Inverter ready for run signal

8 hours

Loading...

Loading...