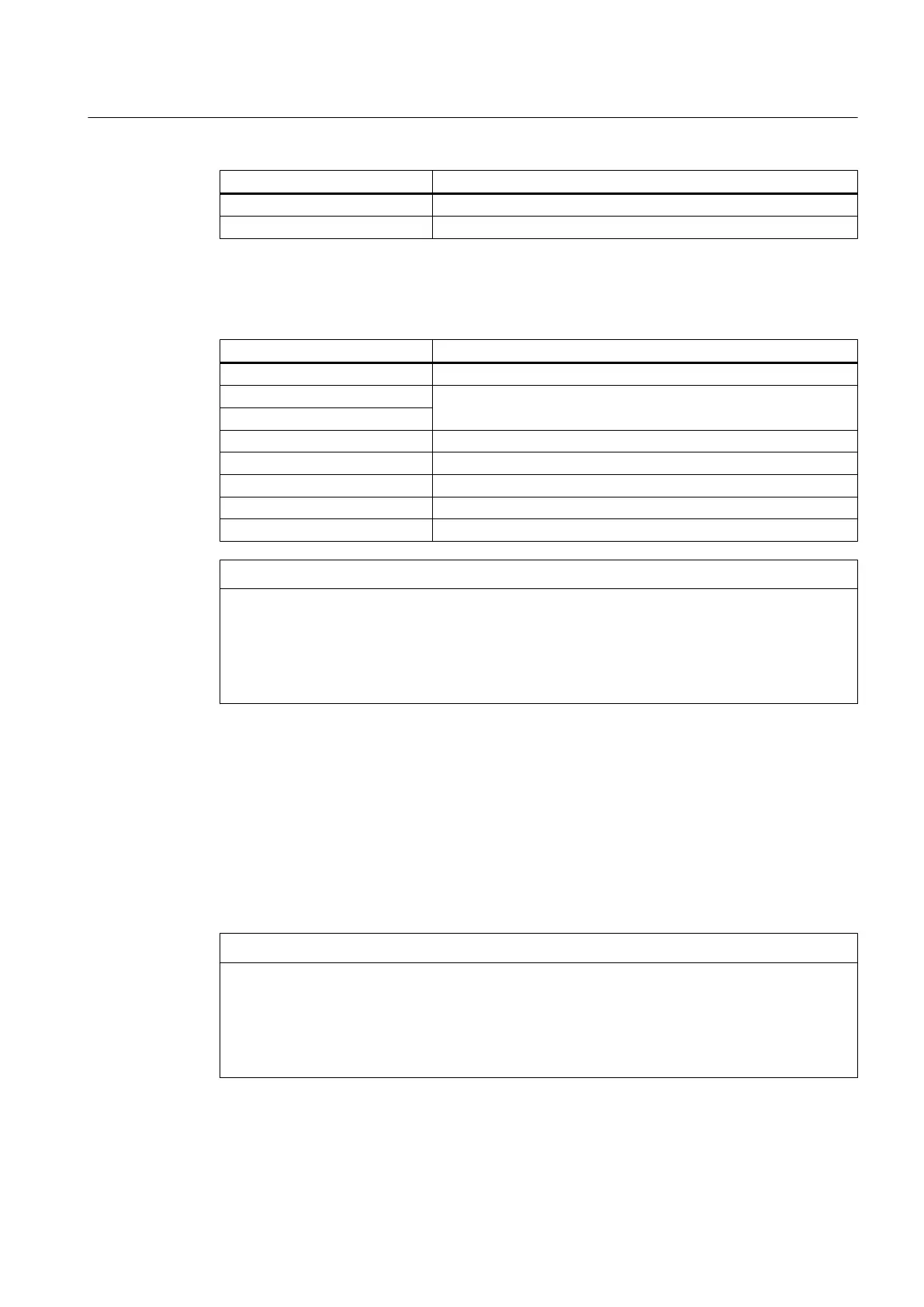

Manufacturer Grease type

Addinol LM 3 EP

FAG Arcanol Multi 3

For motors of horizontal construction you can alternatively use greases with NLGI class 2.

However, this reduces the lubrication interval by 20%.

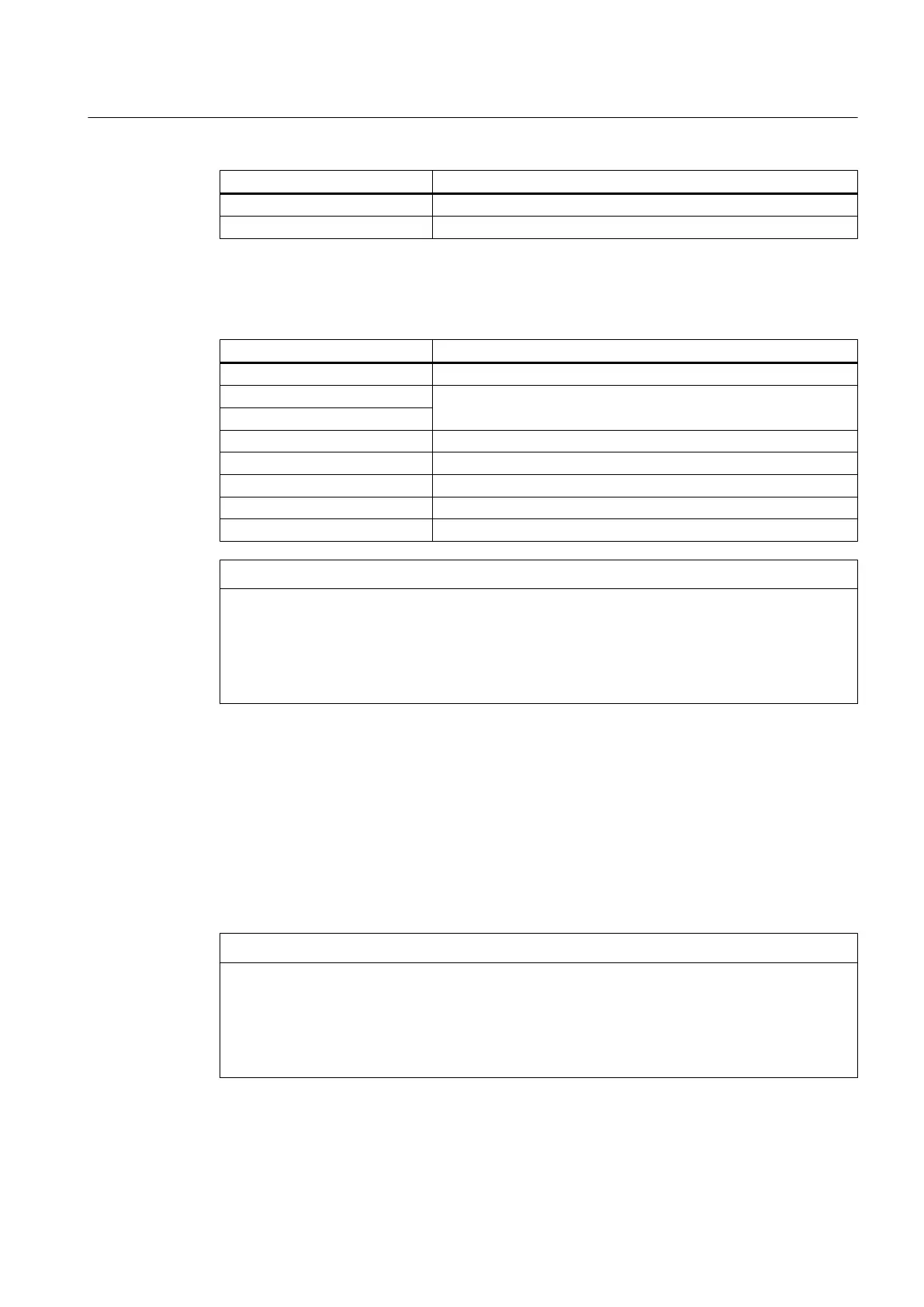

Table 9-3 Alternative greases with NLGI class 2 for motors of horizontal construction

Manufacturer Grease type

Shell Gadus S2 V100 2

ExxonMobil

Unirex N2

Esso

BP Energrease LS2

Castrol Longtime PD2

Lubcon Turmogrease L 802 EP plus

Shell Retinax LX2

FAG Arcanol Multi 2

NOTICE

Diminished lubrication properties by mixing greases

The lubrication properties will be impaired if you mix different greases. This can result in

material damage.

● Avoid mixing greases. Only the manufacturer can provide a guarantee for the miscibility

of particular greases.

Lubrication data

Regreasing data are stated on the lubricant plate of the machine:

● Regreasing intervals in operating hours

● Regreasing amount in grams

● Grease type

Regrease the roller bearing at the latest every 12 months irrespective of the actual number of

operating hours.

NOTICE

Damage to roller bearings

The regreasing intervals for roller bearings are different from the servicing intervals for the

machine. The roller bearings may be damaged if the relubrication intervals are not adhered

to.

● Pay attention to the instructions on the lubricant plate.

Maintenance

9.1 Inspection and maintenance

SIMOTICS HV M 1RN76308PR900CG0-Z

Operating Instructions 07/2018 93

Loading...

Loading...