Technical data and characteristic curves

6.2 Motor overview / assignment of Motor Modules / power cables

S-1FT7 synchronous motors

Configuration Manual, 09/2018, A5E45099423B AA

149

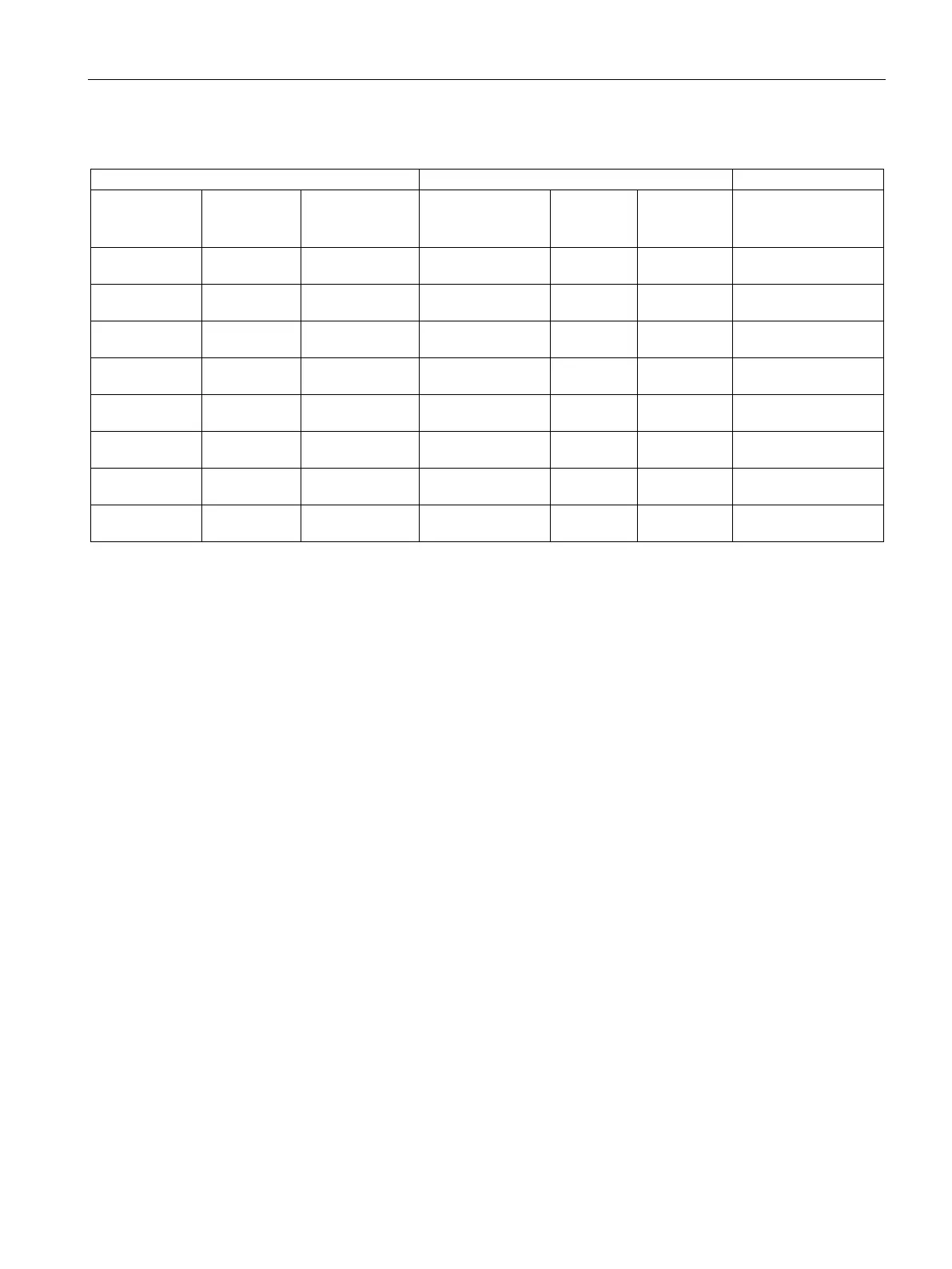

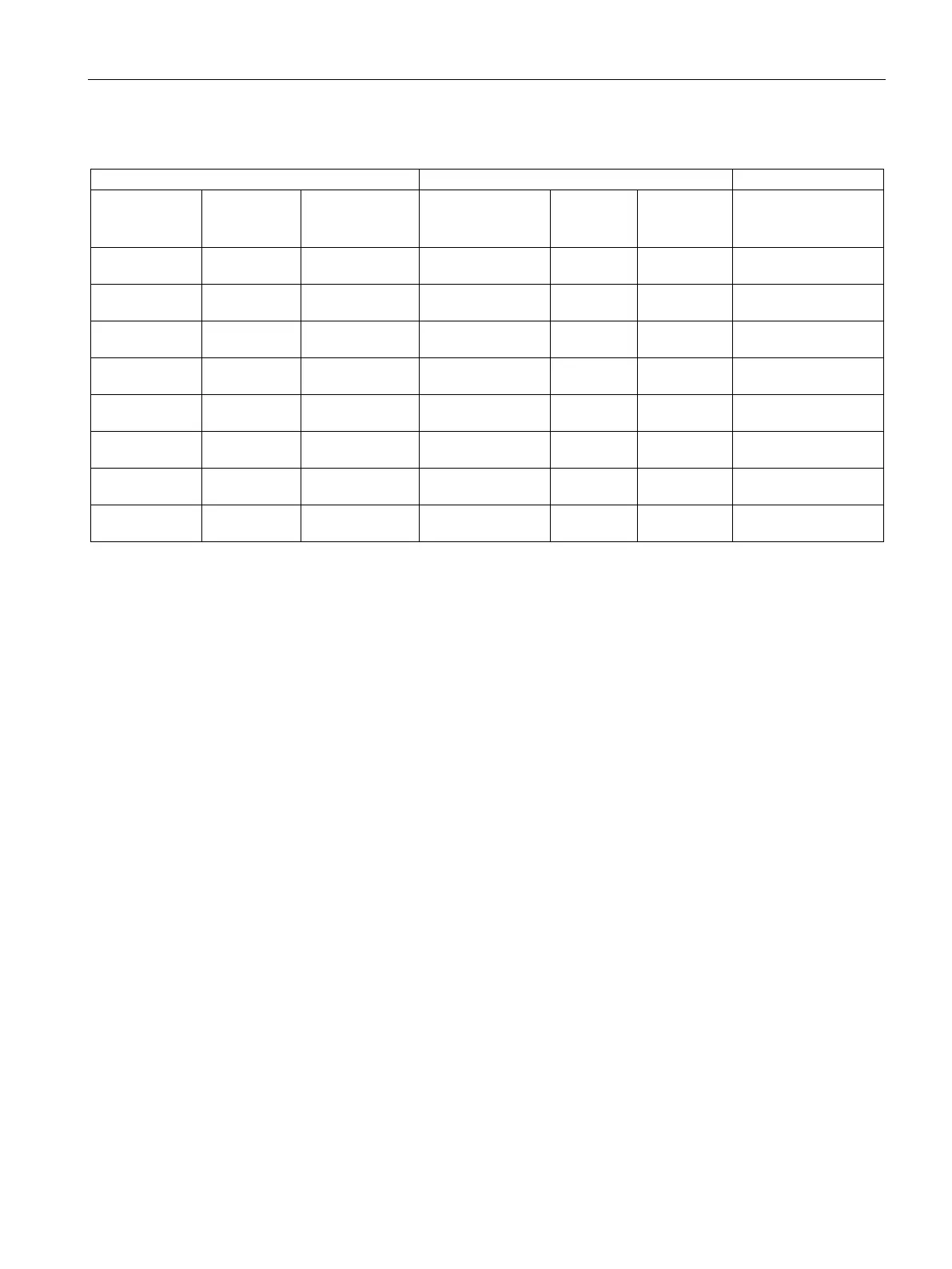

Table 6- 11 1FT7 High Dynamic water cooling

Converter: SINAMICS S120 Booksize

Connector size

5)

/

Cable cross-

section

4)

1FT7065-7WF7 19 1.5 / 4 x 2.5 6SL3120-1TE21-

18 18 6FX❑002-5❑N36-

1FT7065-7WH7 19 1.5 / 4 x 4 6SL3120-1TE23-

30 30 6FX❑002-5❑N46-

1FT7067-7WF7 25 1.5 / 4 x 4 6SL3120-1TE23-

30 30 6FX❑002-5❑N46-

1FT7067-7WH7 25 1.5 / 4 x 4 6SL3120-1TE23-

30 30 6FX❑002-5❑N46-

1FT7085-7WF7 43 1.5 / 4 x 6 6SL3120-1TE24-

45 45 6FX❑002-5❑N54-

1FT7085-7WH7 43 3 / 4 x 16 6SL3120-1TE26-

60 60 6FX❑002-5❑S23-

1FT7087-7WF7 61 3 / 4 x 16 6SL3120-1TE26-

60 60 6FX❑002-5❑S23-

1FT7087-7WH7 61 3 / 4 x 25 6SL3120-1TE28-

85 85 6FX❑002-5❑G33-

The maximum torques of servomotors up to and including stall currents of 30

A are shown

with 3-fold overload capacity. Beyond that with 2-fold.

The Motor Modules are shown as Single Motor Module (6SL3120

-1❑❑❑❑-

❑❑❑❑). Up to

and including 18

A stall current you can also choose Double Motor Modules (6SL3120-

2❑❑❑❑-❑❑❑❑). The last digit of the order number shows the version.

The 4th digit of the order number of pre

-assembled power cables defines the type (5: for

t 500 and 8: for Motion Connect 800 Plus). Via the 9th digit of the order

number the brake connection can be set (C: Without brake cores, and D: with brake

cores). The cable cross

-section for the brake connection is 2 x 1.5 mm². Power cables in

izes 1 and 1.5 are shown as SPEED-

CONNECT. For assigned Motor Modules

for IN > 30

A, the cables on the module side are equipped with ring cable lugs. From con-

nector size 3 onwards, the power connector has a full thread.

The current carrying capacity of

the power cables corresponds to EN 60204-1 for routing

type C under continuous operation conditions at an ambient air temperature of 40 °C.

Loading...

Loading...