Electrical connection

8.3 System integration

S-1FT7 synchronous motors

388 Configuration Manual, 09/2018, A5E45099423B AA

The motor holding brake requires 24 V ± 10 % at the motor connection in order to reliably

open.

● Take into account the voltage drops along the supply cable.

● Use a Control Supply Module (CSM) or a regulated DC power supply, whose setpoint is

set to 26 V.

● Use power supply cables with a minimum cross-section of 1.5 mm².

● Calculate the maximum permissible cable length using the following formula.

If the maximum voltage of 24 V DC +10 % is exceeded, then the brake can close again.

You can approximately calculate the voltage drop Δ

U

for copper cables as follows:

Δ

U

/ V = 0.042 •

x

•

I

Brake

=

l

/

q

/ mm

2

= brake conductor cross-section

Brake

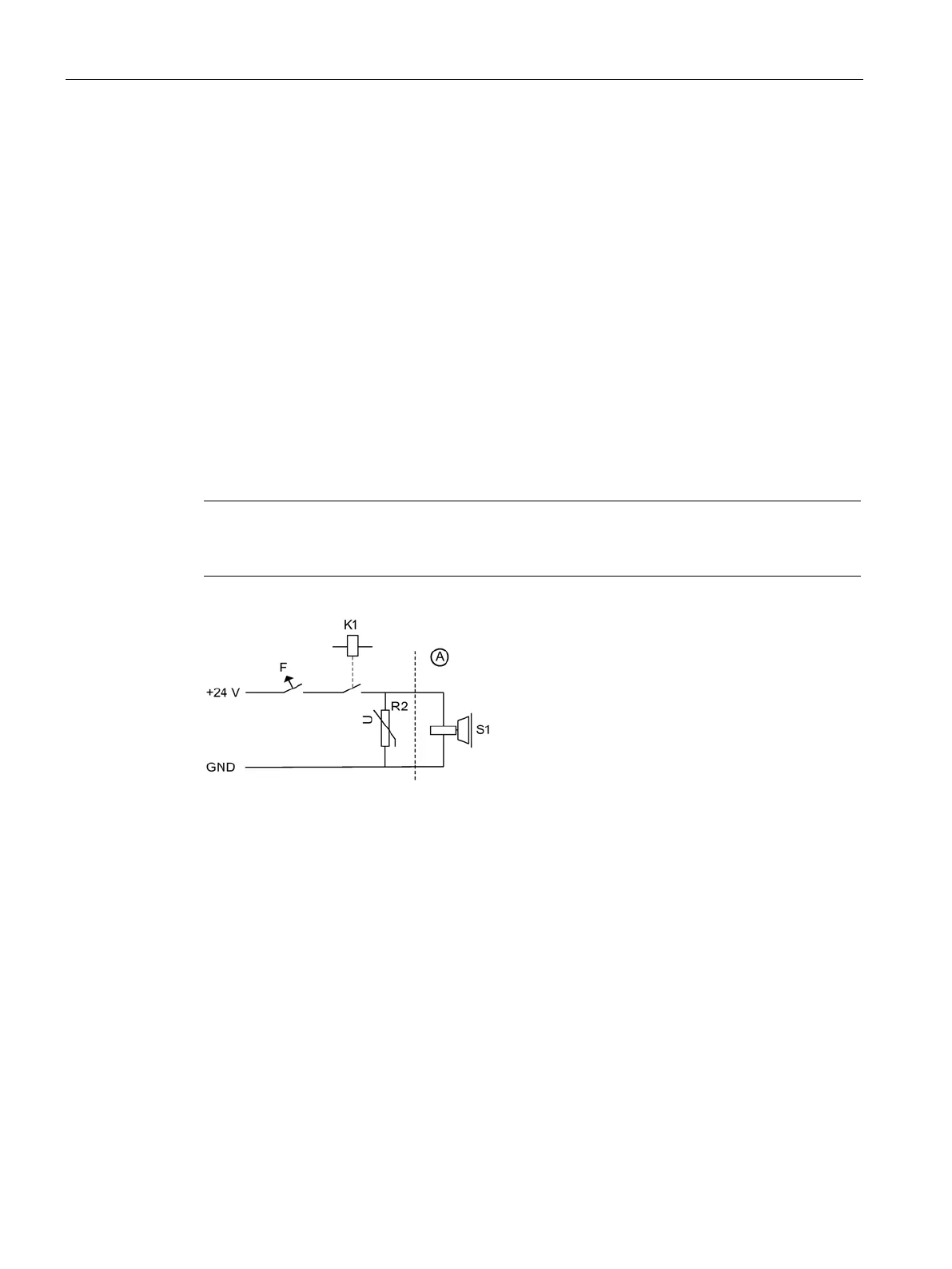

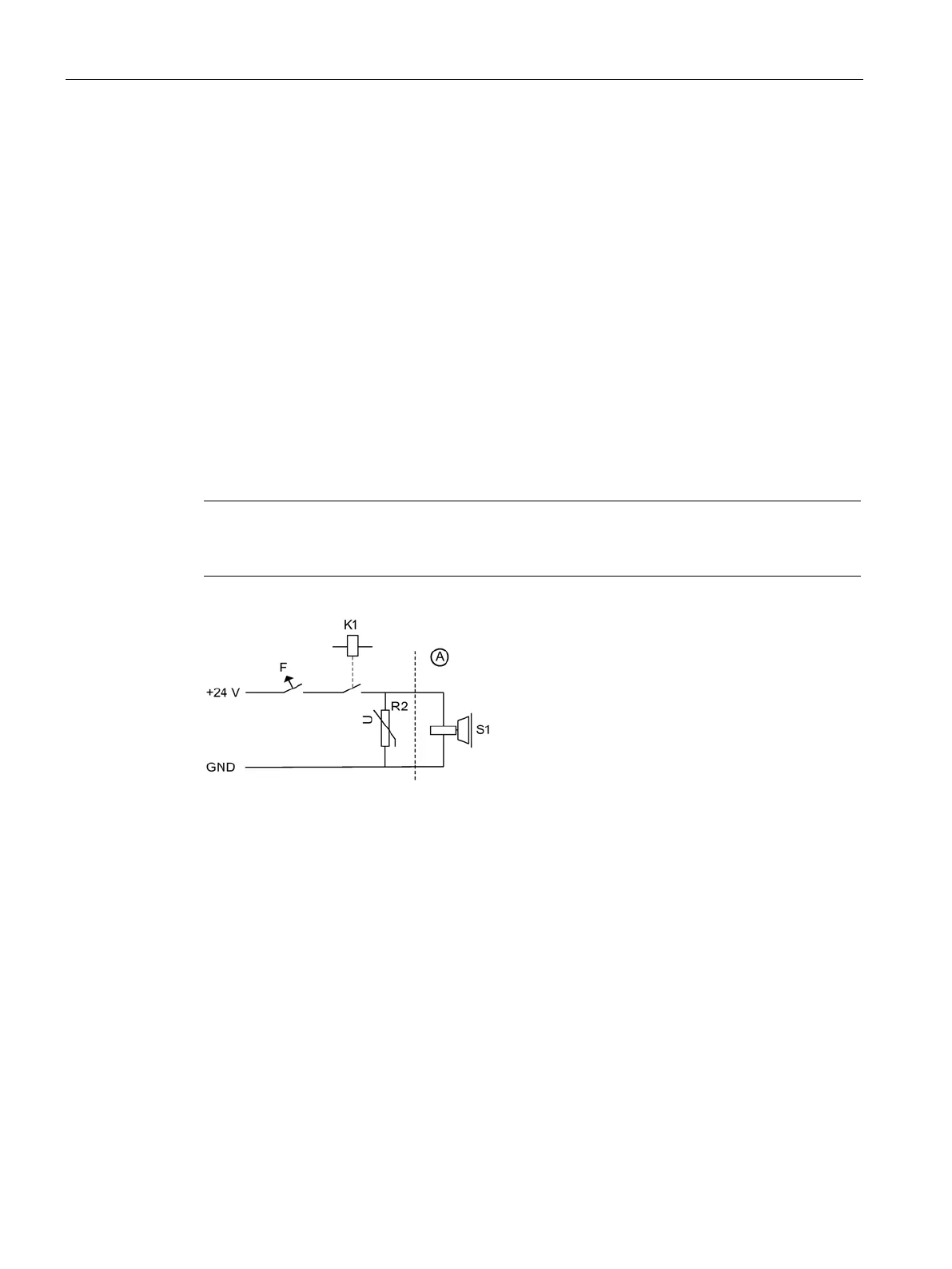

Note

Integrate a protective circuit into the incoming cable. In this way, you avoid

switching

overvoltages and possible influence of the installation environment. See the figure below

Figure 8-9 Suggested circuit for the external power supply with protective circuit

Loading...

Loading...