Mechanical properties

3.1 Cooling

S-1FT7 synchronous motors

Configuration Manual, 09/2018, A5E45099423B AA

45

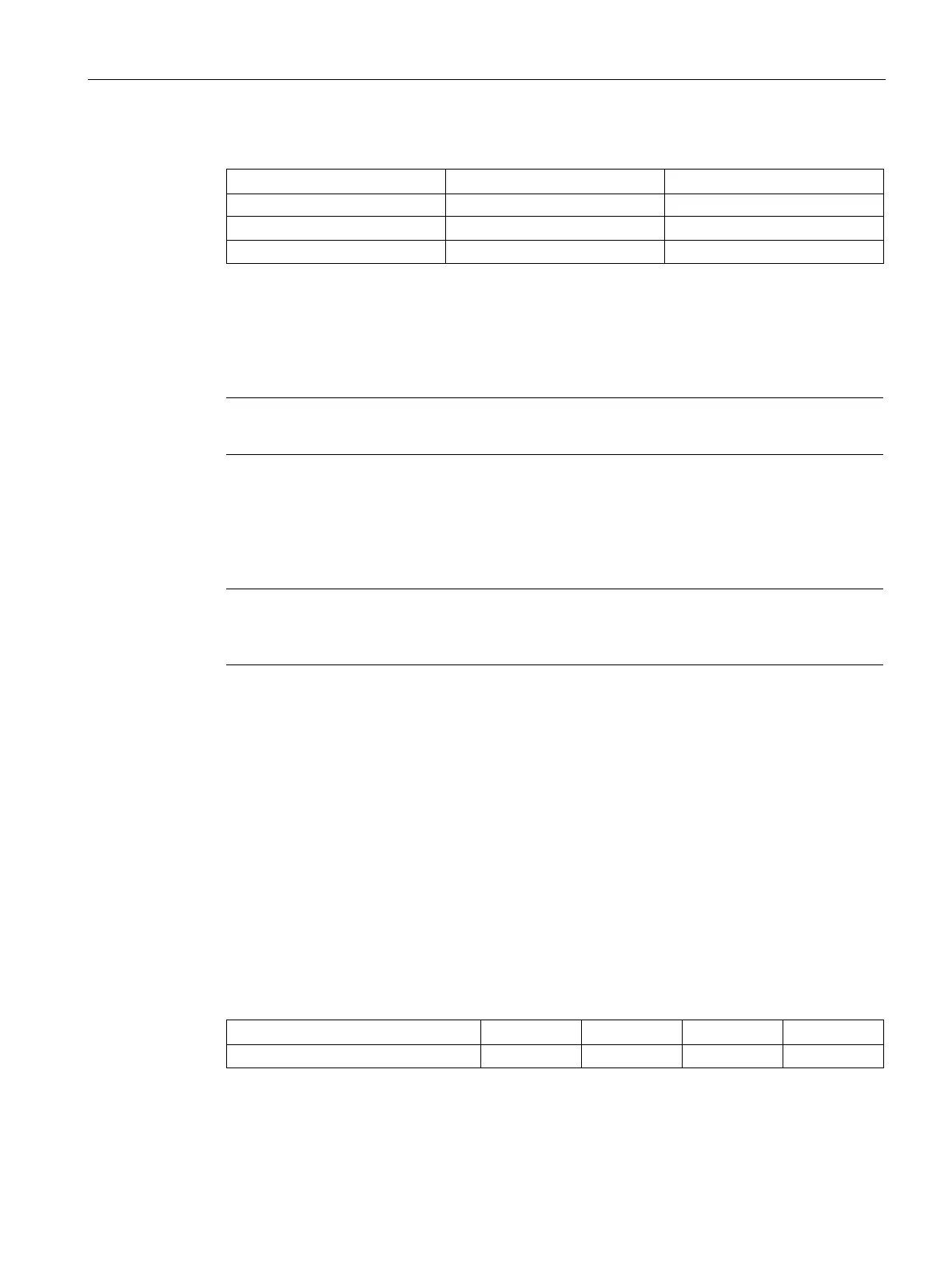

Table 3- 7 Pressure drop at the nominal coolant flow

1FT708x 4 l/min 0.03 MPa

Ensure the nominal coolant flows in the above table for sufficient heat dissipation.

If various components are connected up in the cooling circuit, it may be necessary to

measure the inlet and outlet pressure and adjust accordingly.

Note

Mount flow restrictors on the cooling water outlet of the motor or the relevant component!

● Adjust the pressure, if necessary.

Cooling water inlet temperature

The motors are designed for operation with a cooling water inlet temperature of ≤ 30 °C.

Note

Cooling water temperatures that are lower than the ambient temperature tend to result in

increased water condensation.

● Use the formula below to determine the permissible cooling water inlet temperature to

prevent condensation from forming on the motor surface:

T

cooling water

>

T

ambient

- 5 K

The determined temperature

T

cooling water

is valid for a relative humidity up to approximately

75%.

The cooling water inlet temperature must be higher if the relative humidity is > 75%.

The cooling water inlet temperature can be lowered if the relative humidity is < 75%.

If necessary, a Mollier diagram can be used to determine more precise details.

The permissible rated torque M

N

of the motor changes at a cooling water inlet temperature of

≥ 30 °C.

● Reduce the static torque M

0

according to the derating factor k in the following table.

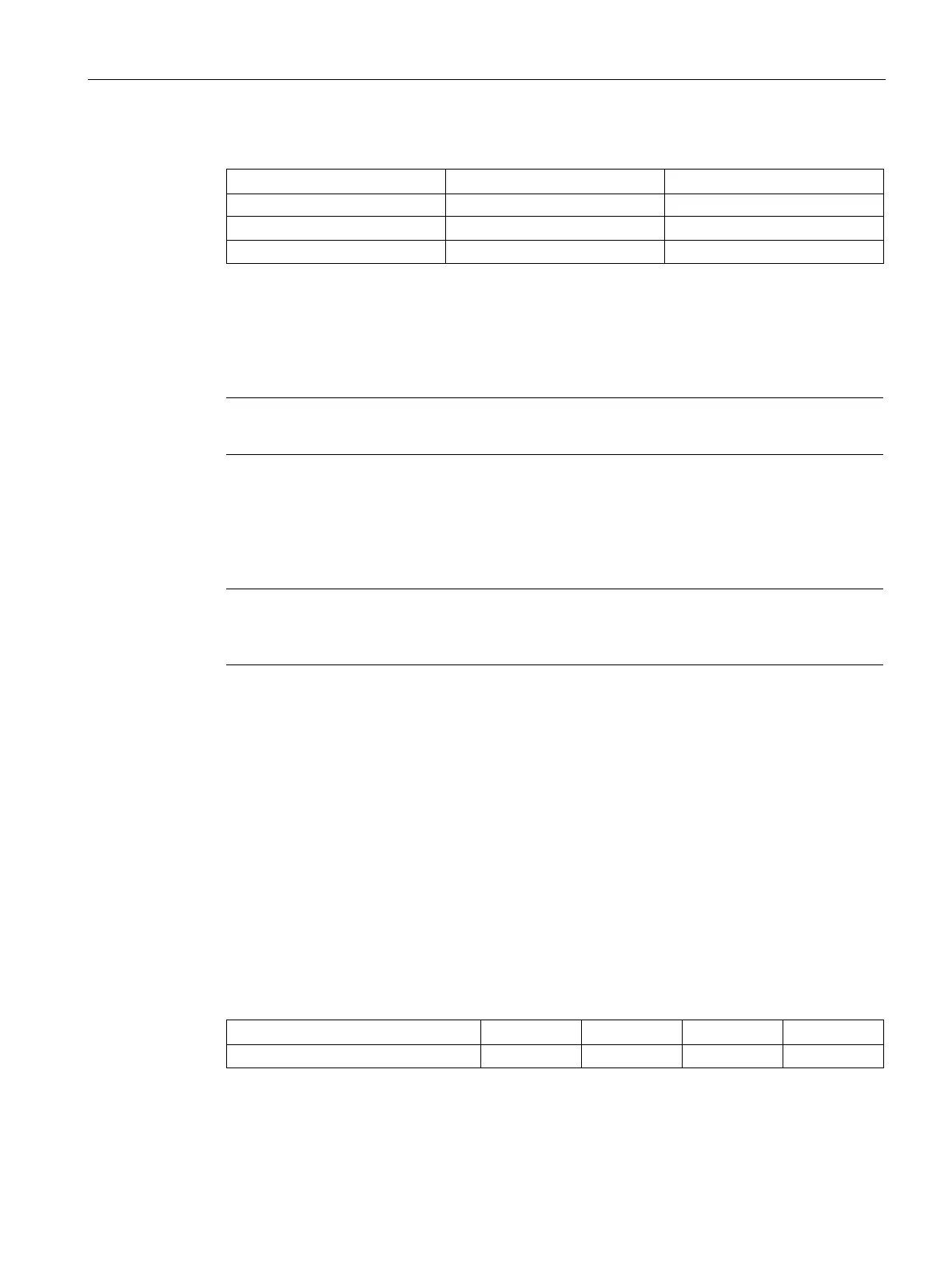

Table 3- 8 Derating factors

Cooling water inlet temperature

Reduce the torque and the speed by the derating factor.

You can calculate the reduced rated torque

M

N red

with the following formula:

M

N red

= M

N

-

(

M

0

-

M

0

*

k

)

Loading...

Loading...